Method for reducing content of ethyl carbamate in wine by utilizing secondary distillation

A technology of medium urethane and urethane, which is applied in the field of urethane content, can solve the problems of reducing the content of urethane, achieve the reduction of urethane content, the result is intuitive and reliable, and the operation is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the removal of ethyl carbamate in Luzhou-flavor liquor

[0030] (1) Use the ultrapure water produced by the Millipore-Q ultrapure water system (Millipore, USA) to reduce the concentration of the original liquor

[0031] To a Luzhou-flavor liquor (72.7%vol, EC concentration 233.33 μg L -1 ) with ultrapure water to reduce the concentration to 28% vol, the volumes of raw wine (1731.2 mL) and water (2817.6 mL) required to reduce the concentration were calculated by mass.

[0032] (2) Pot distillation parameter control

[0033] (1) Choice of pot still: 7.5 L copper pot still, purchased from Portuguese company Iberian Coppers S.A.

[0034] (2) Liquid volume of pot still: 4.5L (not exceeding 2 / 3 of the effective volume).

[0035] (3) Control the feed liquid temperature to 28°C, the ambient temperature to 20°C, and the condensed water to be tap water at normal temperature (the water temperature is about 20°C).

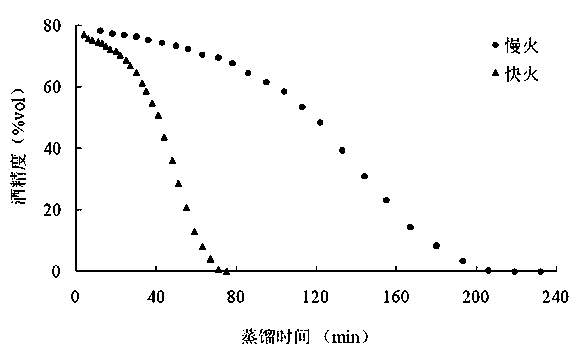

[0036] (4) Heating method: 2000 W electric furna...

Embodiment 2

[0046] Embodiment 2: the removal of ethyl carbamate in fen-flavor liquor

[0047] 1938 mL EC concentration is 110.21 μg L -1 According to Table 2, the raw liquor (65%vol) of a certain Fen-flavor liquor can be obtained after the same fast fire pot distillation as in Example 1, and the concentration of 1232.5 mLEC is lower than 50 μg L -1 Secondary distilled liquor (72% vol), the EC removal rate is as high as 80%, and the alcohol distillation efficiency is over 97%.

[0048] Table 2 Alcohol distillation efficiency and the volume of each fraction, ethyl carbamate (EC) concentration, and EC removal rate of a certain Fen-flavor liquor when it is distilled by fast fire pot

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com