Active and passive compound control system for hybrid power hydraulic excavator

A hydraulic excavator and compound control technology, applied in the field of hydraulic systems, can solve the problems of throttling loss and large discharge, and achieve the effects of eliminating throttling loss, eliminating the need for pilot oil sources, and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

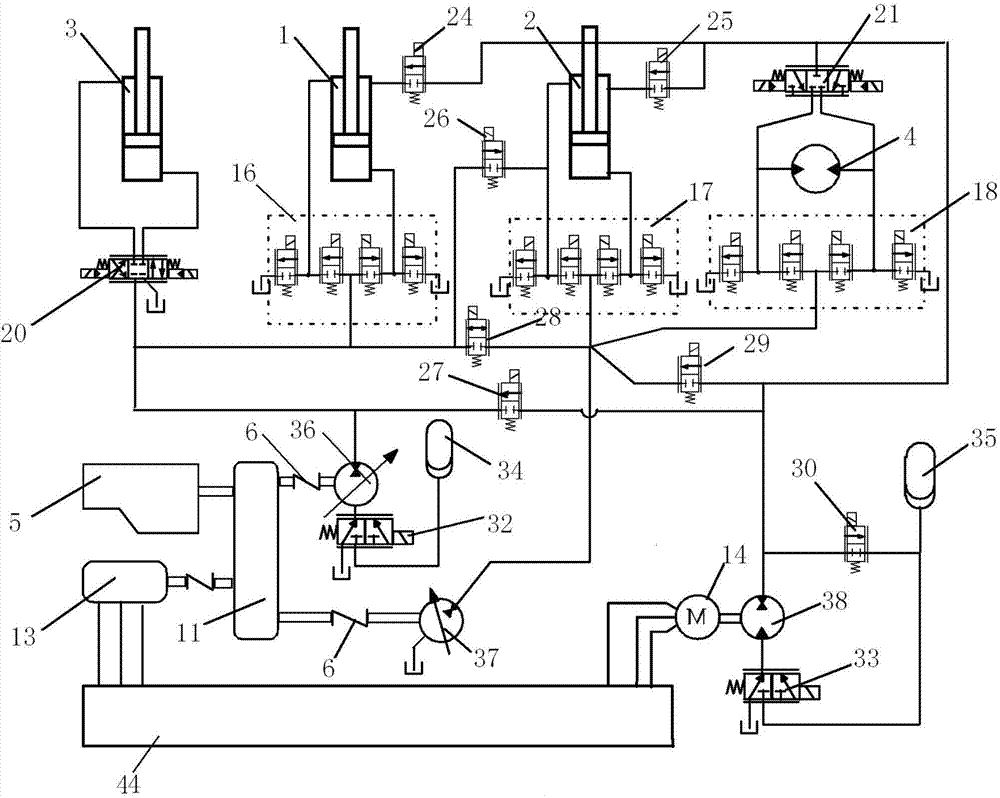

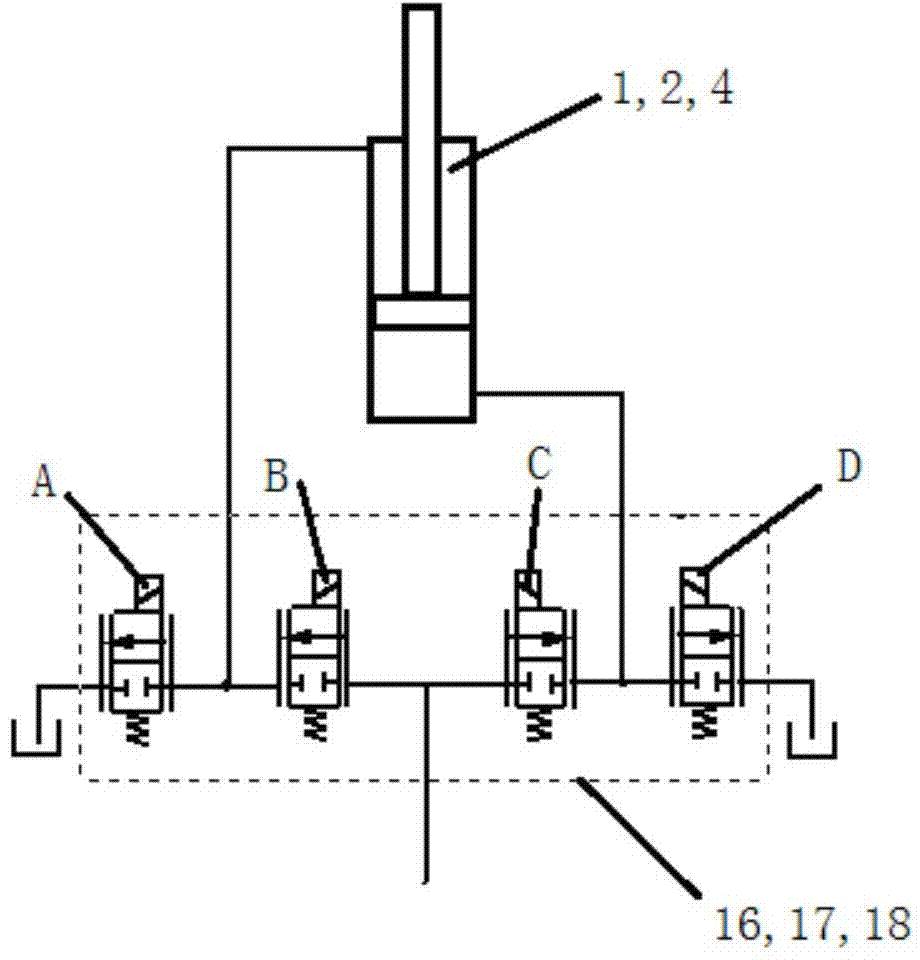

[0037] Such as figure 2 As shown, the active and passive compound control system of the hybrid hydraulic excavator in this embodiment includes boom hydraulic cylinder 1, stick hydraulic cylinder 2, bucket hydraulic cylinder 3, swing motor 4, power source 5, and coupling 6 , transfer case 11, A motor generator 13, B motor generator 14, revolving body 15, power supply system 44 and control circuit, the power supply system includes a shared DC bus 7, a main power switch 8, a rectifier 9, a smoothing capacitor 10, and a storage battery 12 and inverter 40; the control circuit includes boom cylinder control valve group 16, arm cylinder control valve group 17, swing motor control valve group 18, bucket control valve 20, swing control valve 21, and the serial numbers are Ⅰ to Ⅶ The I-VII two-position two-way valves 24-30, the I and II two-position three-way valves 32, 33, the I and II accumulators 34, 35, the A hydraulic pump 36, and the B hydraulic pump 37 and C hydraulic pump 38; ...

Embodiment 2

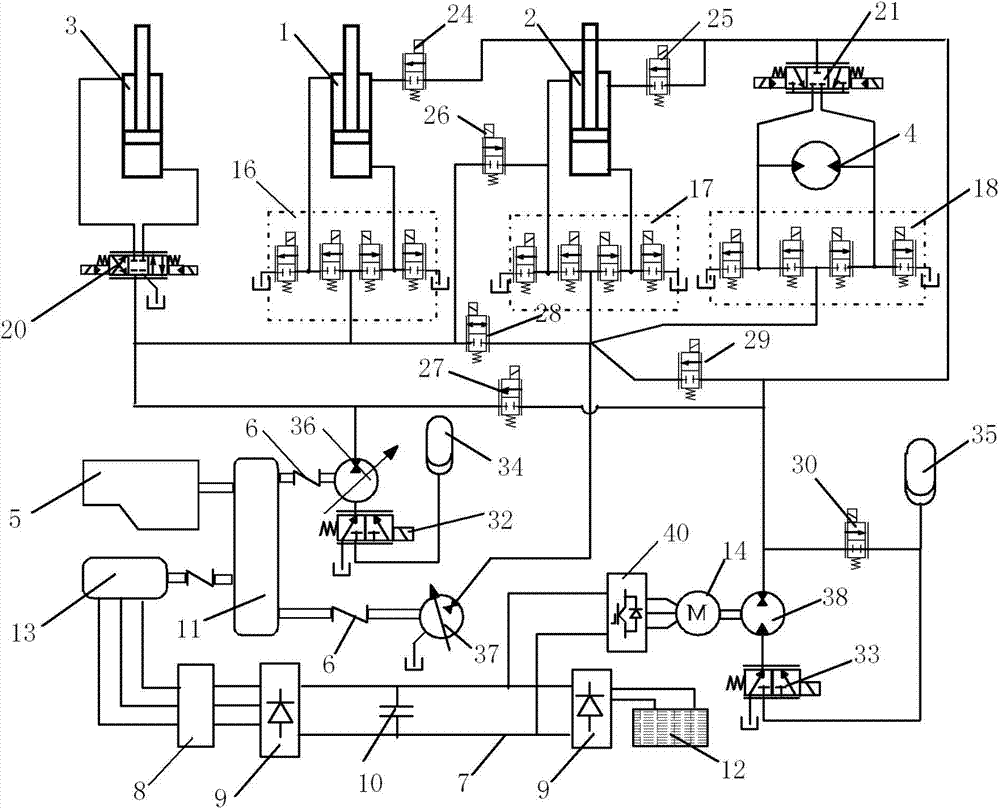

[0044] Such as Figure 4 As shown, the active and passive compound control system of the hybrid hydraulic excavator in this embodiment includes boom hydraulic cylinder 1, stick hydraulic cylinder 2, bucket hydraulic cylinder 3, swing motor 4, power source 5, and coupling 6 , transfer case 11, A motor generator 13, B motor generator 14, rotating body 15, shared DC bus 7, main power switch 8, rectifier 9, smoothing capacitor 10, battery 12, inverter 40 and control circuit, The control loop includes the boom cylinder control valve group 16, the arm cylinder control valve group 17, the bucket control valve 20, the swing control valve 21, and the I-V two-position two-way valves 24 to 28 whose serial numbers are I to V in sequence. , the first two-position three-way valve 32, the first and second accumulators 34, 35, the A hydraulic pump 36, the B hydraulic pump 37; the power source 5 is connected to the transfer case, and the A motor generator is connected to the The transfer case...

Embodiment 3

[0050] Such as Figure 5 As shown, the active and passive composite control system of the hybrid hydraulic excavator in this embodiment includes boom hydraulic cylinder 1, arm hydraulic cylinder 2, bucket hydraulic cylinder 3, swing motor 4, coupling 6, and power source A 41. B power source 42, C power source 43 and the control circuit, the control circuit includes the boom cylinder control valve group 16, the arm cylinder control valve group 17, the swing motor control valve group 18, the bucket control valve 20, and the swing control valve 21. The I-VIII two-position two-way valves 24 to 31, the I and II two-position three-way valves 32, 33, and the I and II accumulators 34 and 35, whose serial numbers are I to VIII in sequence.

[0051] A power source 41, B power source 42, and C power source 43 in the figure all include a power source 5 and a D hydraulic pump 39, and the D hydraulic pump is connected to the power source, and the power source of the A power source is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com