Direct current glow discharge mass-spectrography method for determination of impurity elements in high purity alpha-Al2O3

A technology of DC glow discharge and impurity elements, which is applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., to achieve the effect of simplifying the steps of sample pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

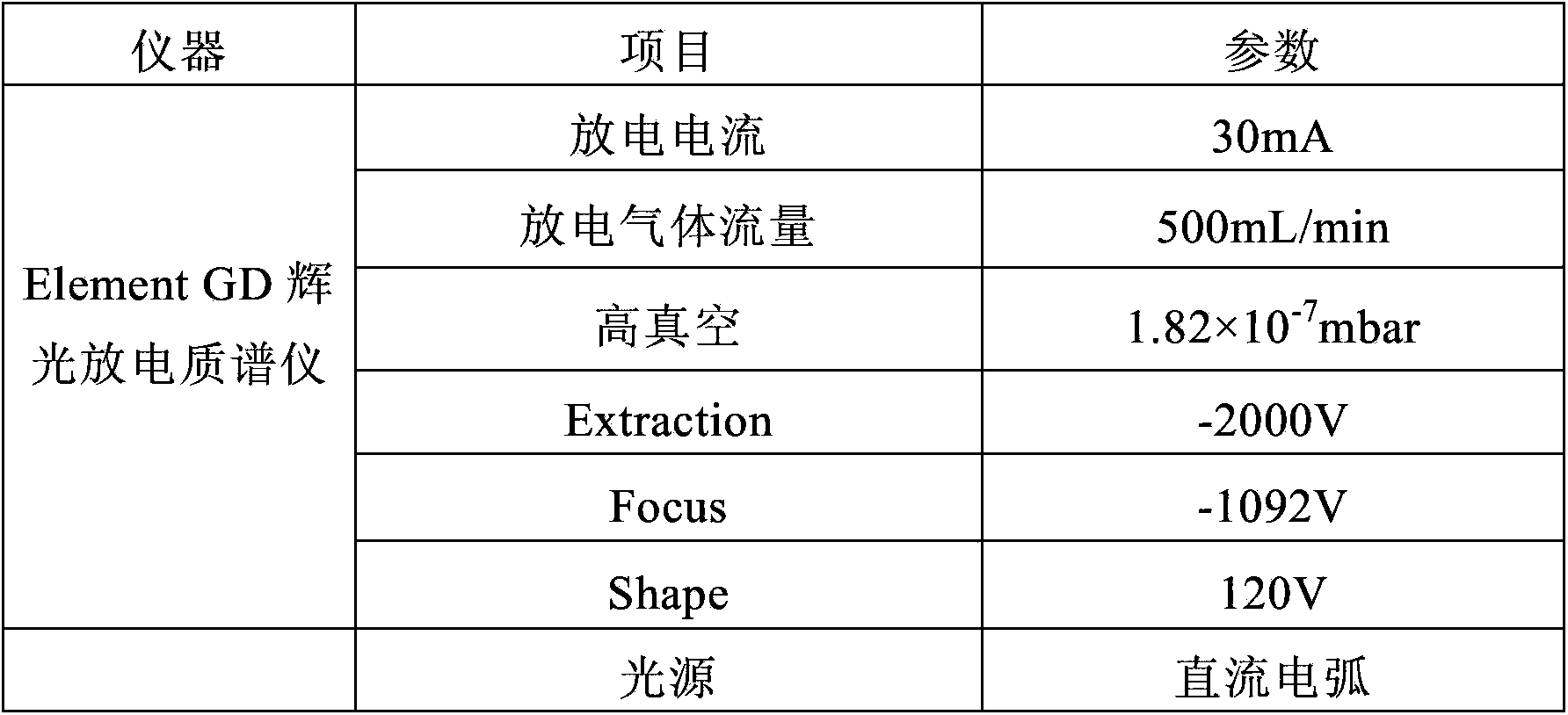

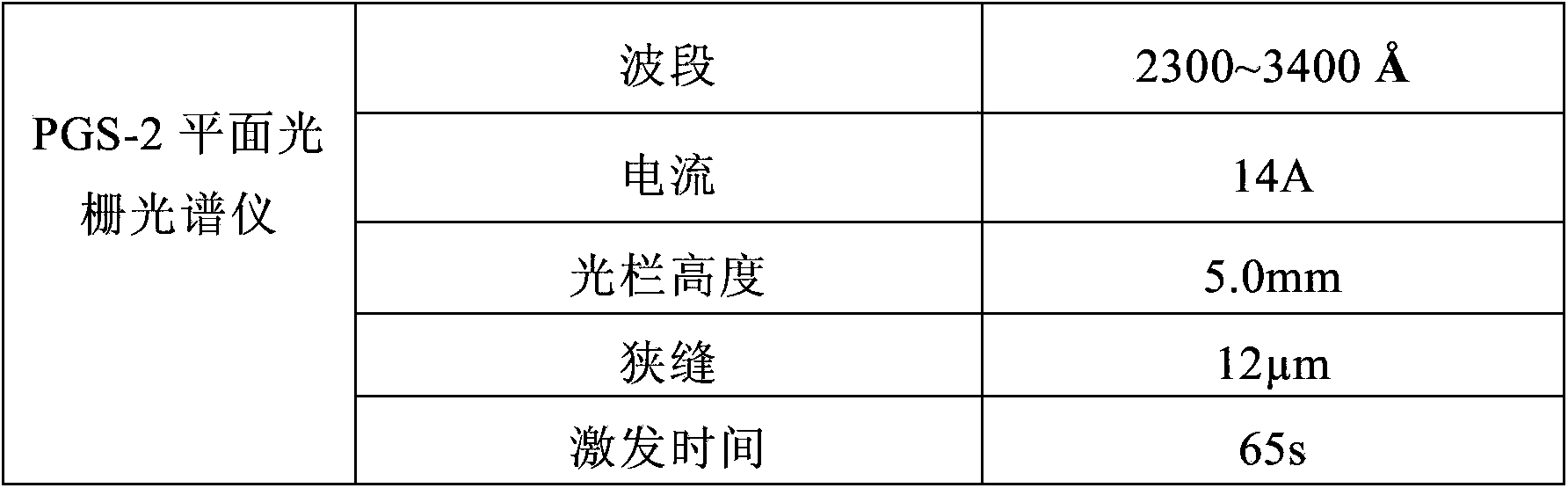

[0025] α-Al 2 o 3 The powder and copper powder (the content of each element to be tested is not higher than 0.1 μg / g) are mixed evenly at a ratio of 1:2, and the appropriate powder is selected by using a DY-60 electric powder tablet press (Tianjin Keqi High-tech Co., Ltd.). Pressure The mixed powder is pressed into tablets, the mold is selected as Φ=20mm, and six tablet samples are prepared in parallel. use N 2 Blow off the powder on the surface of the tableted sample and put it into the sample cell. Element GD glow discharge mass spectrometer (Thermo Fisher, USA) was used to adjust parameters such as discharge current and discharge gas flow rate, as shown in Table 1, and pre-sputter for 15 minutes to remove contamination on the surface of the tablet. Then measure with the measurement parameters in Table 1, collect the signals of the elements to be measured and the matrix elements Al, O and Cu, the instrument automatically gives the content of the elements to be measured in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com