Preparation method of low-heat dried skim milk

A technology of skim milk powder and skim milk, applied in dairy products, milk preparations, applications, etc., can solve the problems of low temperature, high sterilization temperature of milk powder, and inability to kill spores, etc., to improve quality, whey The effect of low protein denaturation and improvement of milk coagulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of low-calorie skimmed milk powder

[0021] (1) Raw milk acceptance: the raw milk is tested, and the follow-up operations are carried out after all indicators are qualified.

[0022] (2) Milk fat separation: the raw milk is heated to 40°C for milk fat separation to obtain skim milk with a fat content of 0.1%.

[0023] (3) Centrifugal sterilization: heat the raw milk to 60°C and centrifuge it in a centrifugal sterilizer with a rotation speed of 10000r / min for 15 minutes.

[0024] (4) Low heat sterilization: Sterilize the milk obtained after centrifugation at 72°C for 10 seconds.

[0025] (5) Vacuum concentration: the sterilized milk is concentrated under the conditions of 50° C. and a vacuum degree of 90 KPa to obtain concentrated milk with a dry matter content of 35%.

[0026] (6) Spray drying: In the spray drying process, the inlet air temperature is 190°C and the exhaust air temperature is 95°C to obtain low-heat skim milk powder.

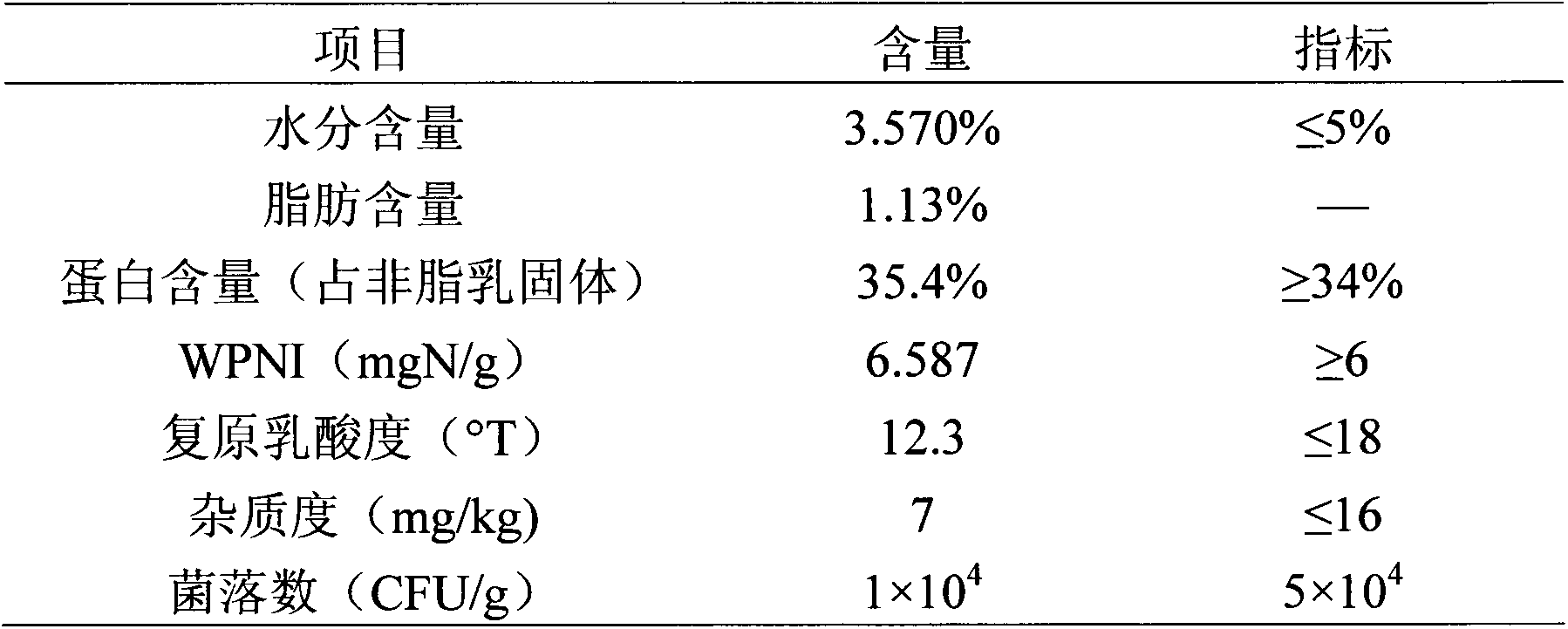

[0027] Table 1 The main ...

Embodiment 2

[0029] Example 2: Preparation of low-calorie skimmed milk powder

[0030] (1) Raw milk acceptance: the raw milk is tested, and the follow-up operations are carried out after all indicators are qualified.

[0031] (2) Milk fat separation: The raw milk is heated to 45°C for milk fat separation to obtain skim milk with a fat content of 0.08%.

[0032] (3) Centrifugal sterilization: heat the raw milk to 55°C and centrifuge it for 20 minutes in a centrifugal sterilizer with a rotation speed of 8000r / min.

[0033] (4) Low heat sterilization: Sterilize the milk obtained after centrifugation at 70°C for 15s.

[0034] (5) Vacuum concentration: Concentrate the sterilized milk at 55° C. and a vacuum degree of 95 KPa to obtain concentrated milk with a dry matter content of 40%.

[0035] (6) Spray drying: In the spray drying process, the inlet air temperature is 190°C and the exhaust air temperature is 95°C to obtain low-heat skim milk powder.

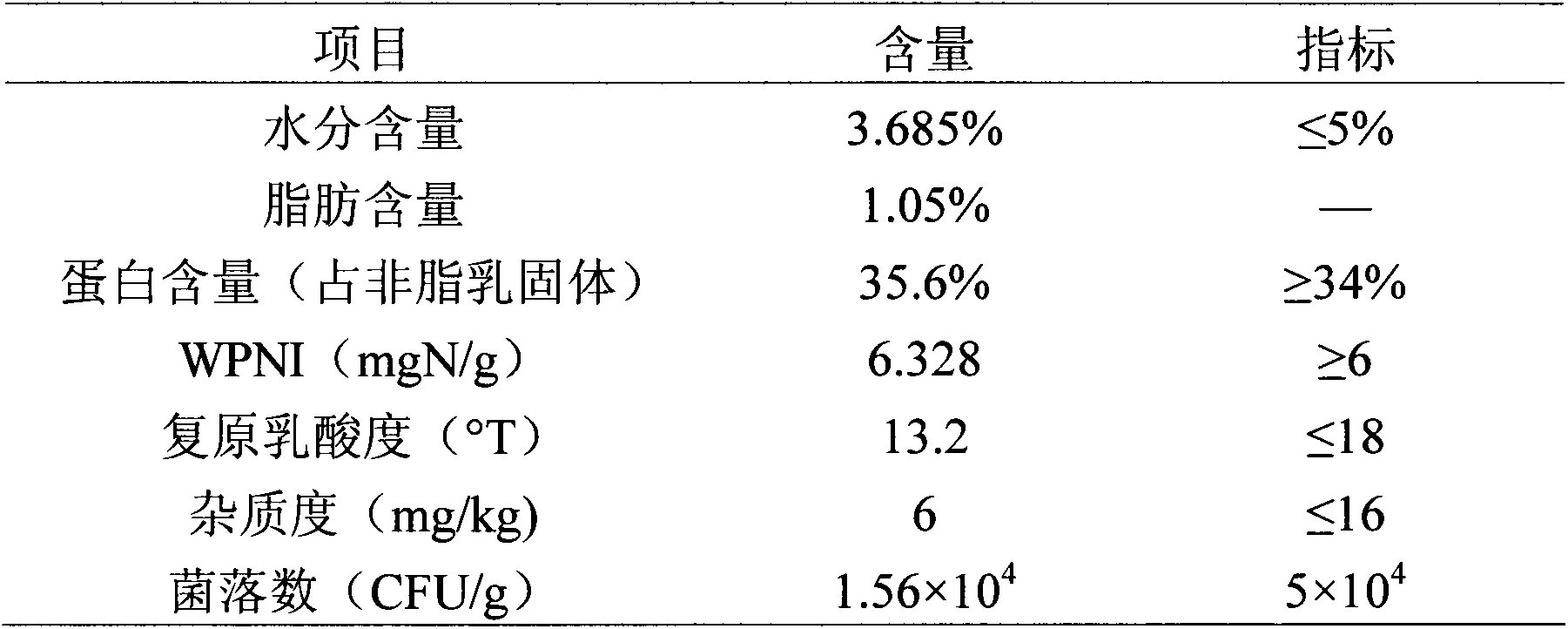

[0036] Table 2 The content of the main components of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com