Production line for wheat aleurone layer content starch flour

A wheat aleurone layer and production line technology, applied in the fields of production line design and mechanical manufacturing design, can solve the problems of long production cycle and complex process flow, and achieve the effects of short production cycle, simple and fast method, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

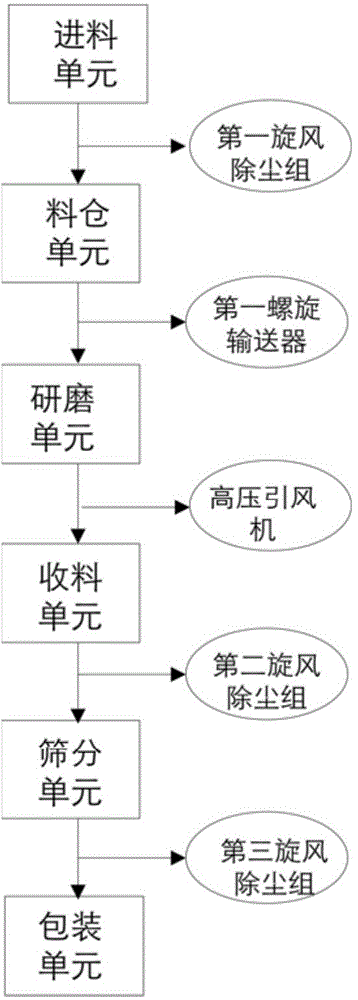

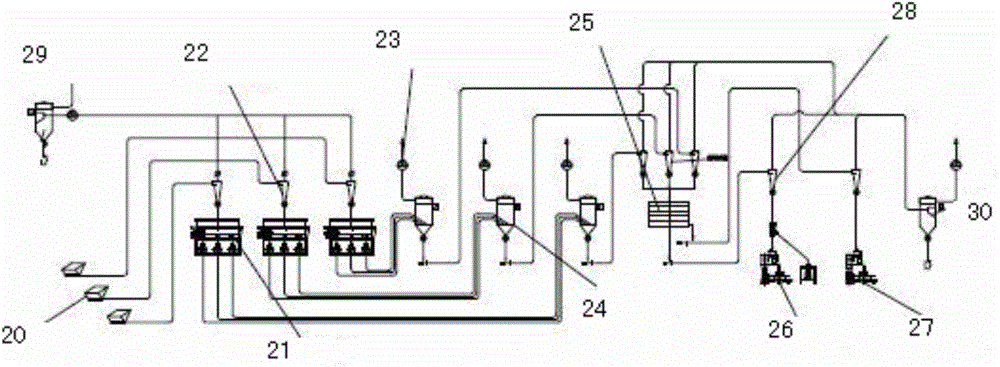

[0032] The invention provides a production line for raw flour processing of wheat aleurone layer content. The production line includes a feeding unit, a silo unit, a grinding unit, a receiving unit, a screening unit and a packaging unit. The material to be processed in the feeding unit enters the silo unit through the first cyclone dedusting group and its discharge valve. There is a first screw conveyor between the silo unit and the grinding unit. The material processed by the grinding unit passes through the high-pressure induced draft fan. Transported to the receiving unit, the material in the receiving unit enters the screening unit through the second cyclone dust removal group and its discharge valve, and the material screened by the screening unit enters the packaging unit through the third cyclone dust removal group and its discharge valve Complete metered packaging. Wherein the feeding unit and the silo unit form the feeding device (20), the screening device (25) is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com