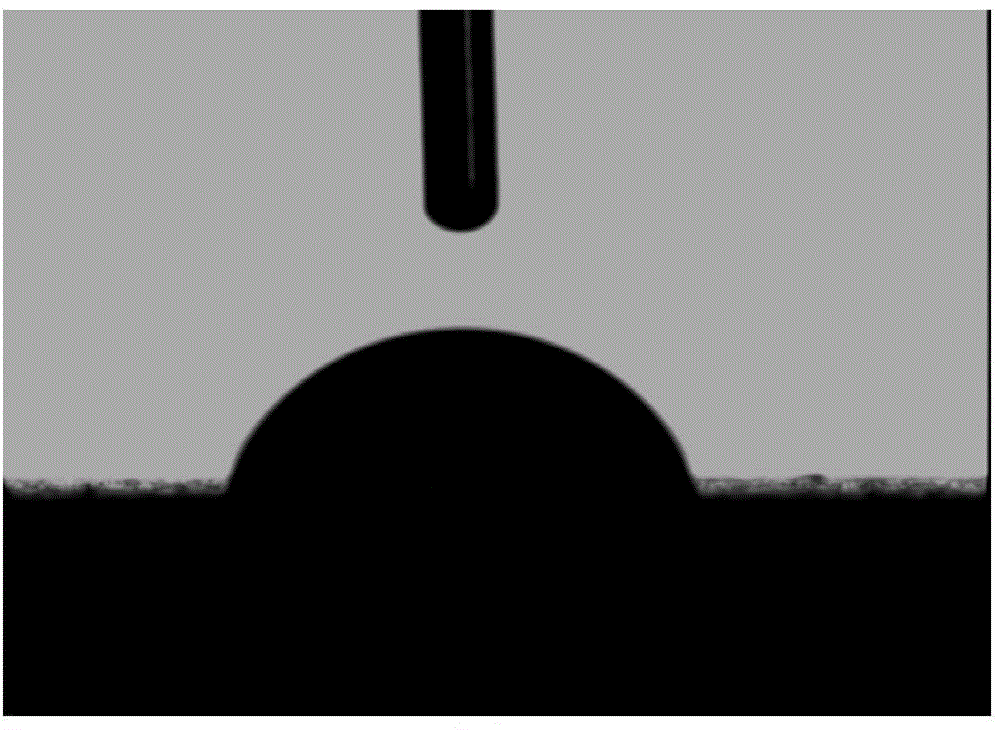

Method for coating biomimetic mineralized assembled super-hydrophilic organic-inorganic hybrid membrane

A biomimetic mineralization and super-hydrophilic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) dissolving polyethyleneimine and polyacrylic acid in water to form solutions of 0.125wt% and 0.025wt% respectively, stirring and ultrasonic defoaming to prepare a film-forming solution;

[0058] (2) Fix the PAN base film on the loading tray of the film carrier, and adjust the speed of the low-speed motor to be constant;

[0059] (3) Place polyethyleneimine, deionized water, and polyacrylic acid solution in the pressure barrel respectively;

[0060] (4) under a pressure of 0.3MPa, the polyethyleneimine solution is sprayed onto the surface of the porous support to form a polycationic film layer on the surface of the support;

[0061] (5) under the pressure of 0.3MPa, deionized water is sprayed onto the surface of the film layer, and the polycation film layer is rinsed;

[0062] (6) Under the pressure of 0.3MPa, the polyacrylic acid solution is sprayed onto the surface of the support, so that the polyanions and polycations react to form a single-layer composite separa...

Embodiment 2

[0080] (1) dissolving polyethyleneimine and polyacrylic acid in water to form solutions of 0.125wt% and 0.025wt% respectively, stirring and ultrasonic defoaming to prepare a film-forming solution;

[0081] (2) Fix the PAN base film on the loading tray of the film carrier, and adjust the speed of the low-speed motor to be constant;

[0082] (3) Place polyethyleneimine, deionized water, and polyacrylic acid solution in the pressure barrel respectively;

[0083] (4) under a pressure of 0.3MPa, the polyethyleneimine solution is sprayed onto the surface of the porous support to form a polycationic film layer on the surface of the support;

[0084] (5) under the pressure of 0.3MPa, deionized water is sprayed onto the surface of the film layer, and the polycation film layer is rinsed;

[0085] (6) Under the pressure of 0.3MPa, the polyacrylic acid solution is sprayed onto the surface of the support, so that the polyanions and polycations react to form a single-layer composite separa...

Embodiment 3

[0103] (1) dissolving polyethyleneimine and polyacrylic acid in water to form solutions of 0.125wt% and 0.025wt% respectively, stirring and ultrasonic defoaming to prepare a film-forming solution;

[0104] (2) Fix the PAN base film on the loading tray of the film carrier, and adjust the speed of the low-speed motor to be constant;

[0105](3) Place polyethyleneimine, deionized water, and polyacrylic acid solution in the pressure barrel respectively;

[0106] (4) under a pressure of 0.3MPa, the polyethyleneimine solution is sprayed onto the surface of the porous support to form a polycationic film layer on the surface of the support;

[0107] (5) under the pressure of 0.3MPa, deionized water is sprayed onto the surface of the film layer, and the polycation film layer is rinsed;

[0108] (6) Under the pressure of 0.3MPa, the polyacrylic acid solution is sprayed onto the surface of the support, so that the polyanions and polycations react to form a single-layer composite separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com