Catalyst carrier and application thereof

A catalyst carrier, photocatalysis technology, applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instruments and methods, etc., can solve the problem of less active sites, and achieve the effect of improving catalytic activity and improving active sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

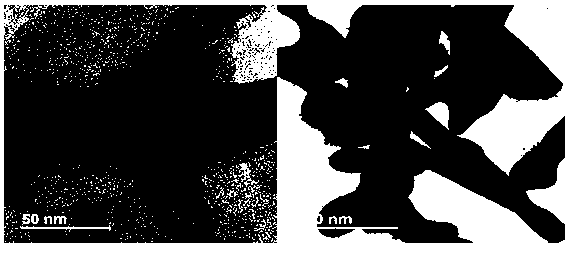

[0033] (Step 1) Preparation of Catalyst Support α-Fe 2 o 3 / RGO solution: the catalyst carrier α-Fe 2 o 3 / RGO is dissolved in the mixed solution of water and methanol and stirred evenly, the concentration of the catalyst carrier is 0.1 mg / mL, and the volume ratio of water and methanol is 1:1;

[0034] (step 2) prepare the aqueous solution of chloroplatinic acid and surfactant PVP respectively, the concentration of the aqueous solution of described chloroplatinic acid is 50mg / mL, the concentration of the aqueous solution of described surfactant PVP is 45mg / mL, then equal volume The aqueous solution of chloroplatinic acid and surfactant PVP is injected in the catalyst carrier solution simultaneously, and wherein the mass ratio of chloroplatinic acid and catalyst carrier is 10:1, and the mass ratio of surfactant PVP and catalyst carrier is 5:1; At the same time, the solution was irradiated with visible light for 90 min.

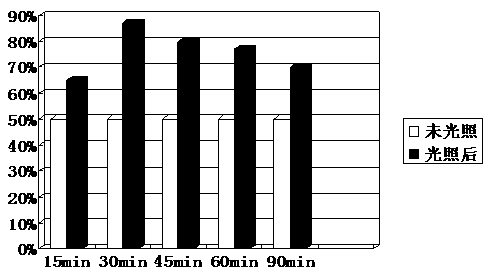

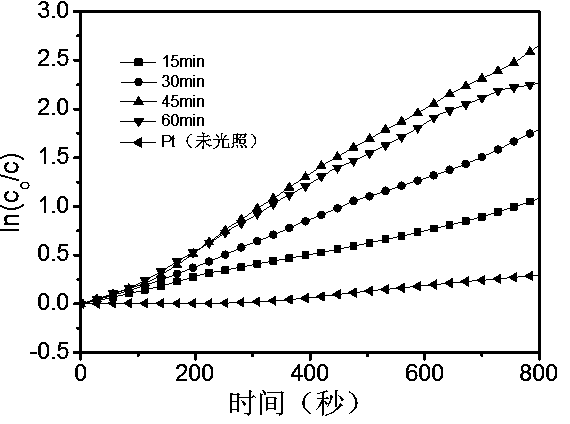

[0035] (Step 3) Samples were taken at different time p...

Embodiment 2

[0037] (Step 1) Preparation of Catalyst Support α-Fe 2 o 3 / RGO solution: the catalyst carrier α-Fe 2 o 3 / RGO is dissolved in the mixed solution of water and methanol and stirred evenly, the concentration of the catalyst carrier is 5 mg / mL, and the volume ratio of water and methanol is 1:3;

[0038] (step 2) prepare the aqueous solution of chloroplatinic acid and surfactant PVP respectively, the concentration of the aqueous solution of described chloroplatinic acid is 100mg / mL, the concentration of the aqueous solution of described surfactant PVP is 80mg / mL, then equivolume The aqueous solution of chloroplatinic acid and surfactant PVP is injected in the catalyst carrier solution simultaneously, and wherein the mass ratio of chloroplatinic acid and catalyst carrier is 20:1, and the mass ratio of surfactant PVP and catalyst carrier is 10:1; The solution was irradiated with visible light for 90 min.

[0039] (Step 3) Samples were taken at different time periods of light, an...

Embodiment 3

[0041] (Step 1) Preparation of Catalyst Support TiO 2 / RGO solution: the catalyst carrier TiO 2 / RGO is dissolved in the mixed solution of water and methanol and stirred evenly, the concentration of the catalyst carrier is 10mg / mL, and the volume ratio of water and methanol is 3:1;

[0042] (step 2) prepare the aqueous solution of chloroplatinic acid and surfactant PVP respectively, the concentration of the aqueous solution of described chloroplatinic acid is 5mg / mL, the concentration of the aqueous solution of described surfactant PVP is 3mg / mL, then equal volume The aqueous solution of chloroplatinic acid and surfactant PVP is simultaneously injected in the catalyst carrier solution, wherein the mass ratio of chloroplatinic acid and catalyst carrier is 2:5, and the mass ratio of surfactant PVP to catalyst carrier is 1:10; The solution was irradiated with visible light for 90 min.

[0043] (Step 3) Samples were taken at different time periods of light, and then the decompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com