Metal microstructure direct forming method based on electric spark discharging deposition additive manufacturing

A technology of discharge deposition and additive manufacturing, which is applied in the coating process and coating of metal materials, and can solve the problems of expensive processing equipment, limited processing depth, and small processing gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

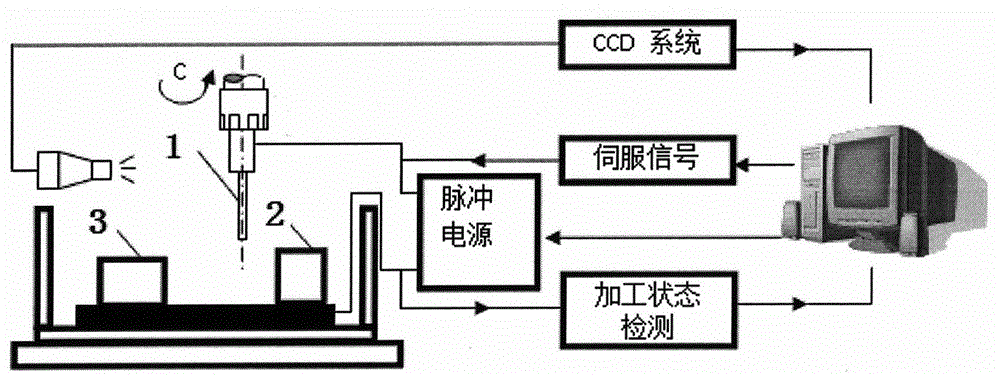

[0025] An embodiment of the present invention provides a method for direct forming of metal microstructures based on EDM additive manufacturing, including the following steps:

[0026] S1. Using a cylindrical tool electrode (500 microns in diameter) to connect the positive electrode of the pulse power supply to the processing polarity, using kerosene as the working medium, and preparing the tool electrode with the required diameter through the reverse handcuffing process of the fine electric spark block electrode;

[0027] S2. Connect the workpiece and the tool electrode prepared in step S1 to the negative pole and the positive pole of the pulse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com