Rapidly degradable plant fiber building decoration material and preparation method thereof

A technology of building decoration materials and plant fibers, which is applied in the field of plant fiber building decoration materials and its preparation, can solve the problems of uneven product structure, low surface finish, weak anti-aging ability, etc., and achieve good appearance finish and excellent mechanical properties , The effect of strong degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The rapidly degradable plant fiber building decoration material is prepared from the following raw materials in weight percentage: 40% bamboo and wood fiber, 12% corn starch, 15% talcum powder, 13% pulp, and 18% adhesive. Bamboo fiber is 40% and wood fiber is 10% in bamboo wood fiber. The selected bamboo fiber has a length of 0.3-2.0mm, a diameter of 0.125-0.225mm, and a width distribution of 10-15um.

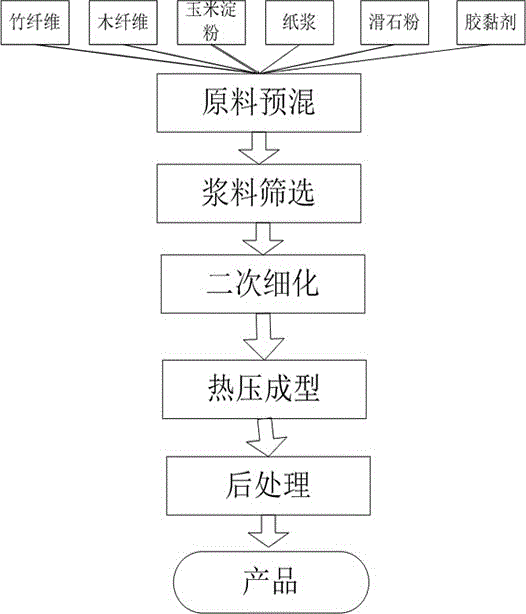

[0029] The method for preparing the described rapidly degradable plant fiber building decoration material comprises the following steps:

[0030] The first step, raw material premixing: according to the proportioning requirements, take bamboo fiber, wood fiber, corn starch, talcum powder, paper pulp, and adhesive that meet the weight percentage according to the proportioning requirements and add them to the mixer to stir and mix evenly to obtain a mixed slurry. The speed of the mixer is 300 rpm.

[0031] The second step, slurry screening: transfer the mixed slurry obta...

Embodiment 2

[0037] The rapidly degradable plant fiber building decoration material is prepared from the following raw materials in weight percentage: 47% bamboo and wood fiber, 13% corn starch, 13% talcum powder, 17% pulp, and 10% adhesive. Among the bamboo and wood fibers, bamboo fiber is 37.6%, and wood fiber is 9.4%. The selected bamboo fiber has a length of 0.3-2.0mm, a diameter of 0.125-0.225mm, and a width distribution of 10-15um.

[0038] The method for preparing the described rapidly degradable plant fiber building decoration material comprises the following steps:

[0039] The first step, raw material premixing: according to the proportioning requirements, take bamboo fiber, wood fiber, corn starch, talcum powder, paper pulp, and adhesive that meet the weight percentage according to the proportioning requirements and add them to the mixer to stir and mix evenly to obtain a mixed slurry. The speed of the mixer is 200 rpm.

[0040] The second step, slurry screening: transfer the ...

Embodiment 3

[0046] The rapidly degradable plant fiber building decoration material is prepared from the following raw materials in weight percentage: 43% bamboo and wood fiber, 8% corn starch, 17% talcum powder, 14% pulp, and 18% adhesive. Among the bamboo and wood fibers, bamboo fiber is 42.4%, and wood fiber is 10.6%. The selected bamboo fiber has a length of 0.3-2.0mm, a diameter of 0.125-0.225mm, and a width distribution of 10-15um.

[0047] The method for preparing the described rapidly degradable plant fiber building decoration material comprises the following steps:

[0048] The first step, raw material premixing: according to the proportioning requirements, take bamboo fiber, wood fiber, corn starch, talcum powder, paper pulp, and adhesive that meet the weight percentage according to the proportioning requirements and add them to the mixer to stir and mix evenly to obtain a mixed slurry. The speed of the mixer is 200 rpm.

[0049] The second step, slurry screening: transfer the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com