An all-in-one anaerobic membrane bioreactor that effectively reduces membrane fouling

An anaerobic membrane biology and membrane fouling technology, applied in anaerobic digestion treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of serious membrane fouling, high cleaning and renewal costs, etc. Reduced losses and improved shearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

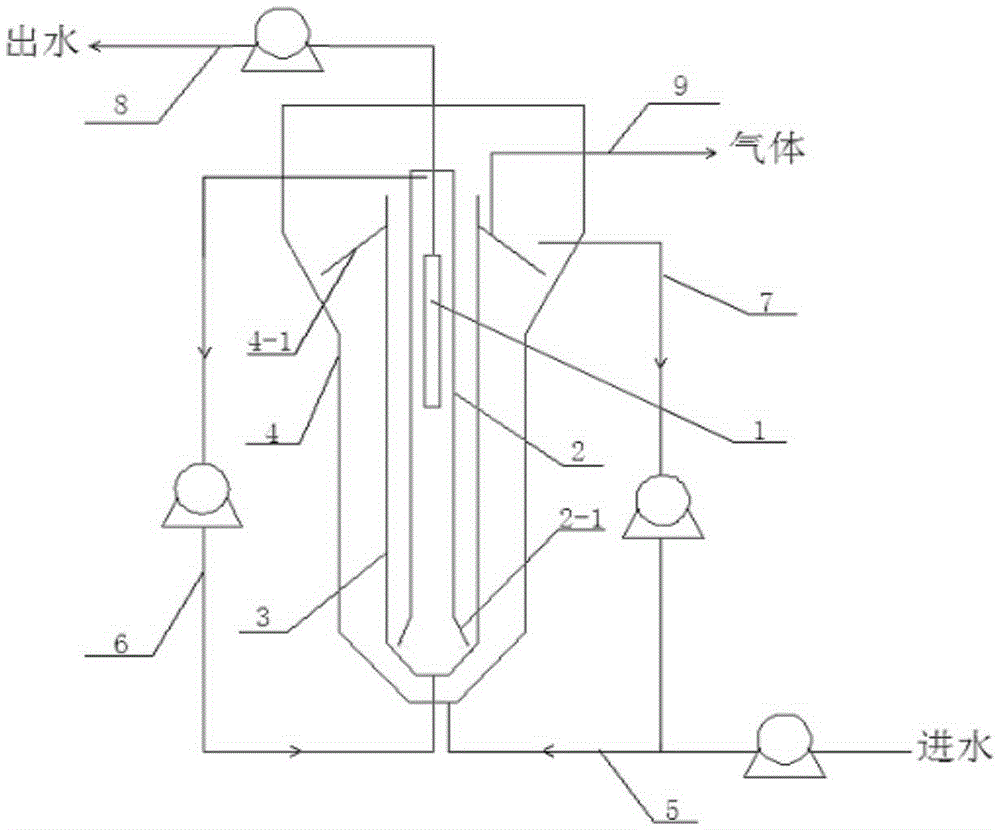

[0019] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is an effective low membrane fouling integrated anaerobic membrane bioreactor, from the inside to the outside is the inner tube membrane module 1, the inner tube 2, the middle tube 3 and the outer tube 4, it also A three-phase separator 4-1, an outlet pipe 8, an air collecting pipe 9, an inlet pipe 5 and an outer cylinder return pipe 7 are provided, the three-phase separator 4-1 is arranged in the sedimentation area of the outer cylinder 4, and the outlet pipe 8 and the inner cylinder membrane module The top of 1 is connected, the gas collecting pipe 9 is connected with the gas phase separation area of the three-phase separator 4-1, the water inlet pipe 5 is connected with the bottom of the outer cylinder 4, and one end of the return pipe 7 of the outer cylinder is connected with the outer cylinder 4 and is located in the third Above the item separator 4-1, the other end of ...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the distance between the bottom edge of the water inlet 2-1 of the inner cylinder and the inner wall of the middle cylinder 3 is less than 0.5-0.8 cm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the lower part of the middle tube 3 is an inverted triangle. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com