Multistage settling and garden sewage regenerating system

A regeneration system and gardening technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor treatment effect and low treatment efficiency, and achieve low equipment investment, Low operating cost, improved flocculation effect and settling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

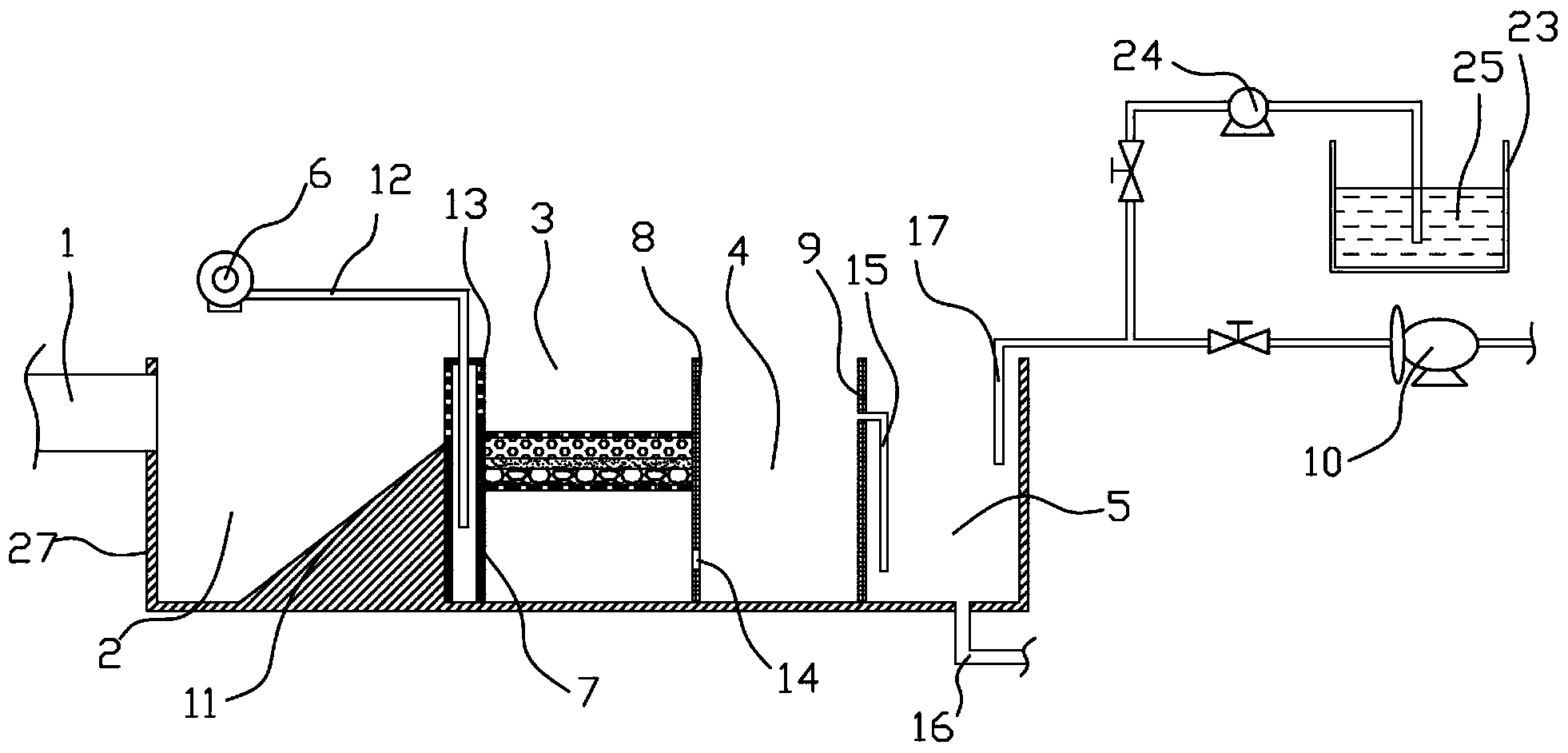

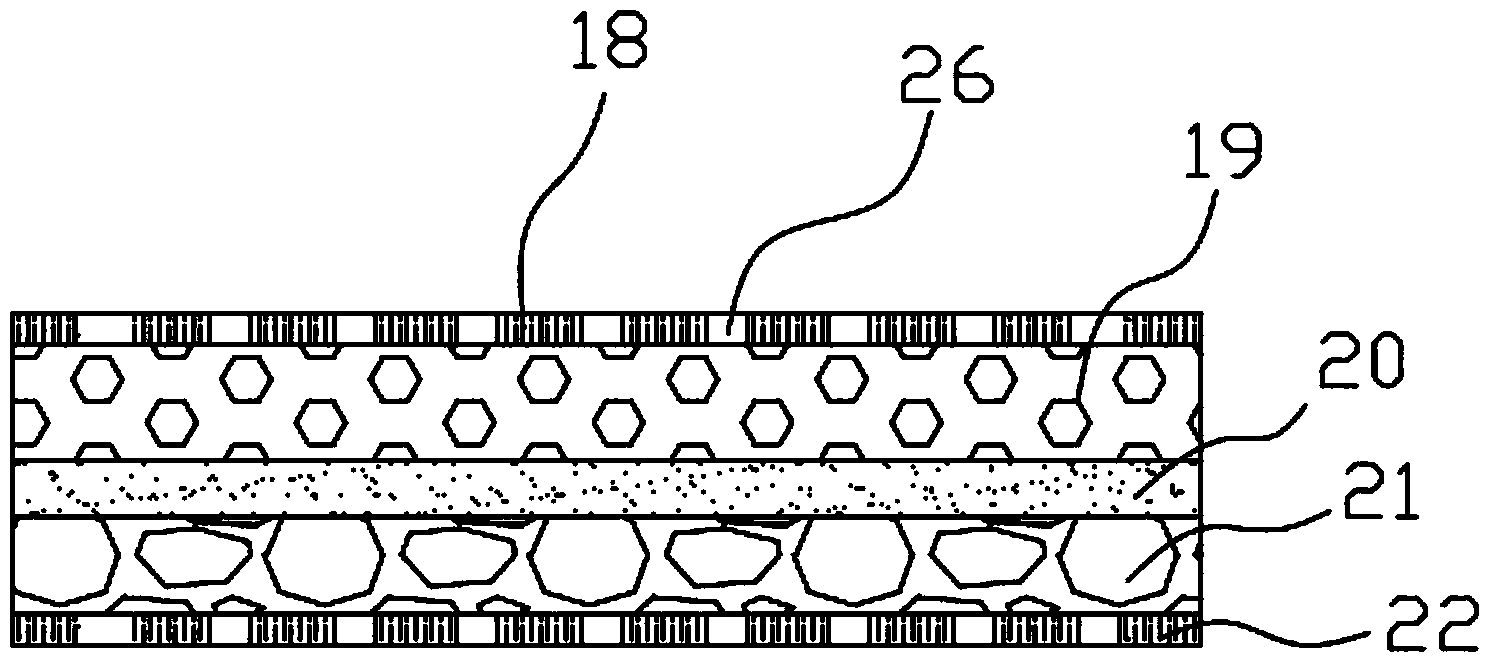

[0021] Such as figure 1 A kind of multi-stage settlement garden sewage regeneration system shown, comprises diversion ditch 1, air blower 6, sedimentation treatment tank 27, inflatable splint 7, first clapboard 8, second clapboard 9 and self-priming pump 10, inflatable splint, The first partition and the second partition are fixed in the sedimentation treatment tank and divide the inner space of the sedimentation treatment tank into a slow flow settlement zone 2, a filter zone 3, a buffer zone 4 and a flocculation settlement zone 5, and the water diversion ditch is located on the upper part of the slow flow settlement zone And connected with it, the bottom of the slow flow settlement area is provided with an upwardly inclined slow flow slope 11 near the side of the inflatable splint, the slope of the slow flow slope is 45°, the inflatable splint is fitted with the slow flow slope, and the inflatable splint is provided with a cavity. An inflatable tube 12 is provided in the cav...

Embodiment 2

[0023] The difference between this example and Example 1 is that the flocculant is made by the following method: by 1% FeCl 3 , 1% Al 2 (SO 4 ) 3 , 0.8% pullulan, 2% bentonite, and the balance is the mass percentage of water. After weighing each component, FeCl 3 with Al 2 (SO4 ) 3 Add water, stir continuously for 3 hours, then age for 2 days, then add bentonite and stir for 1 hour at a speed of 1000 r / min, and finally add pullulan and stir for 1 hour at a speed of 200 r / min, and the rest are exactly the same as in Example 1.

Embodiment 3

[0025] The difference between this example and Example 1 is that the flocculant is made by the following method: by 0.7% FeCl 3 , 0.6% Al 2 (SO 4 ) 3 , 0.7% pullulan, 1.8% bentonite, and the balance is the mass percentage of water. After weighing each component, FeCl 3 with Al 2 (SO 4 ) 3 Add in water, stir continuously for 2.5h, then age for 1.5d, then add bentonite and stir at a high speed of 800r / min for 1.5h, finally add pullulan and stir at a speed of 120r / min for 1.2h, and the rest are the same as those in the examples 1 is exactly the same.

[0026] The operating principle of the present invention is: the sewage is collected into the slow-flow settlement area through the diversion ditch, and heavy impurities such as stones in the sewage in the slow-flow settlement area will sink at the bottom under the blocking of the slow-flow slope and the action of its own gravity. The sewage overflows to the filter area through the grid holes on the inflatable splint. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com