System for processing breeding and slaughtering sewage and technology for system

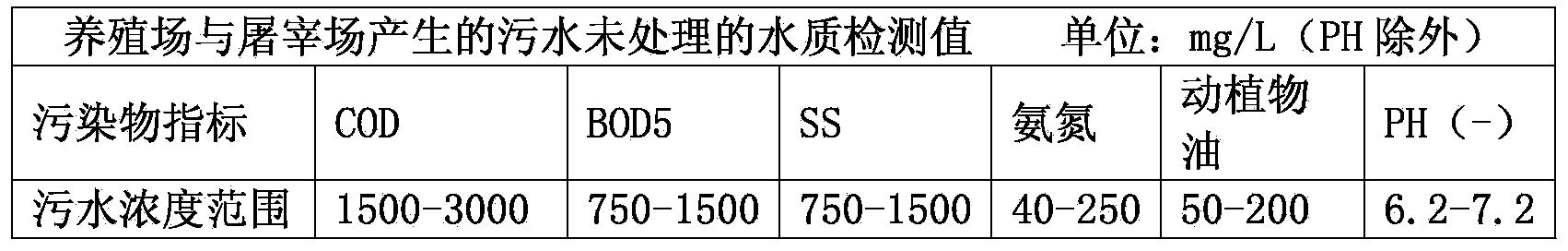

A technology for slaughtering sewage and sewage, applied in filtration treatment, multi-stage water treatment, aerobic process treatment, etc., can solve the problems of many solid impurities, endanger ecological health and safety, increase the difficulty of pretreatment technology, etc., and achieve good degradation effect. , the effect of eliminating odorous gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

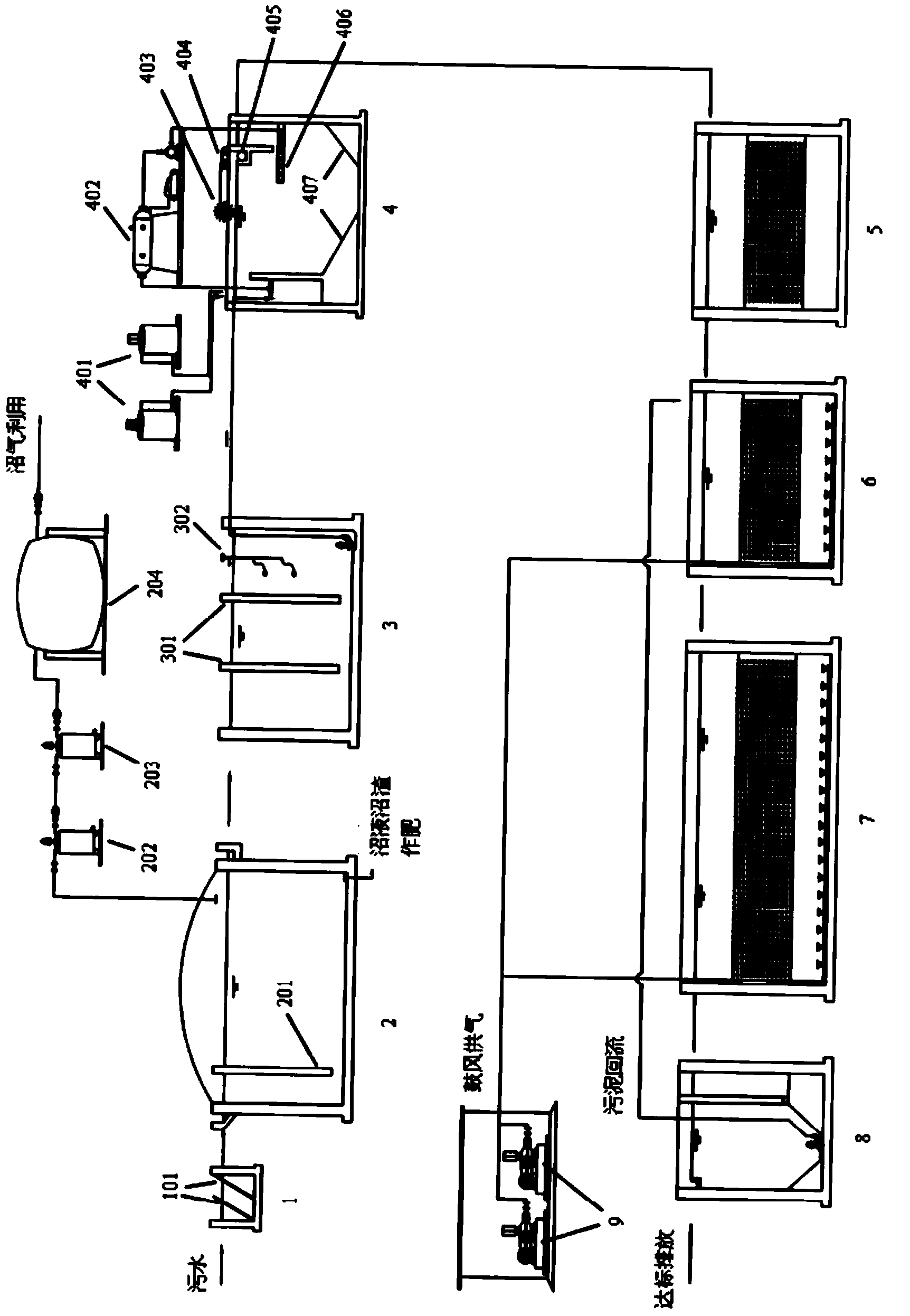

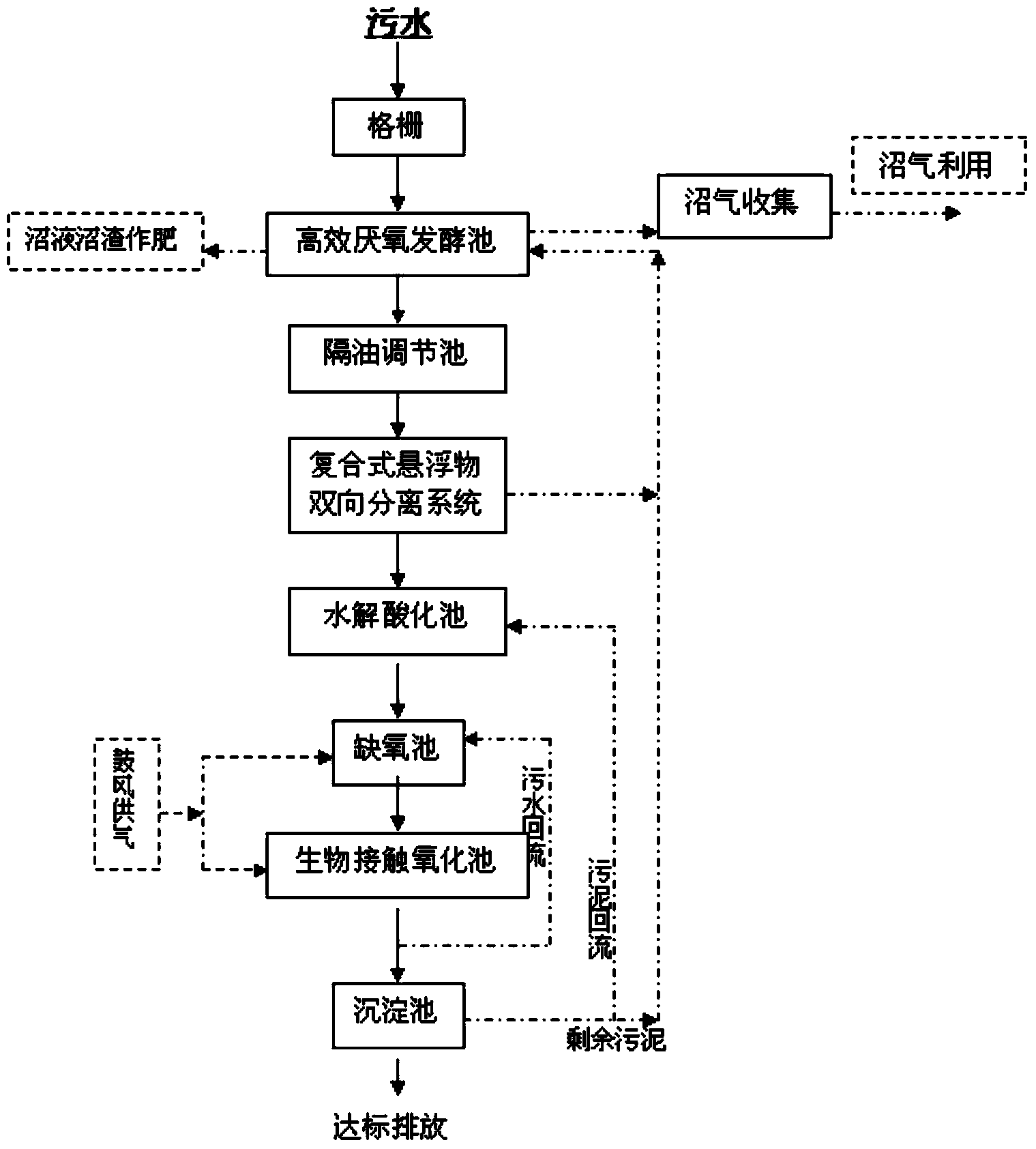

[0031] combine figure 1 It can be seen that the system for treating breeding and slaughtering sewage includes: grille channel 1, which is provided with an inlet channel composed of backward-inclined grille 101; The baffle wall panel 201 in the internal space of the anaerobic fermentation tank 2 is separated into a front section and a rear section, and the grid canal 1 communicates with the front section of the anaerobic fermentation tank 2; the oil separation regulating tank 3 is provided with The oil-separating baffle 301 suspended at the bottom is used to separate the internal space of the oil-separating adjustment tank 3, and is divided into multiple sections, which can be divided into front section, middle section and back section or separated into sequentially continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com