Beryllium oxide crucible for smelting pure beryllium, and preparation method thereof

A technology for beryllium oxide and crucibles, which is applied in the field of beryllium oxide crucibles for pure beryllium smelting and its preparation, can solve the problems of crucibles with poor thermal shock resistance, complicated production methods, and long preparation cycles, etc. The effect of short preparation cycle and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

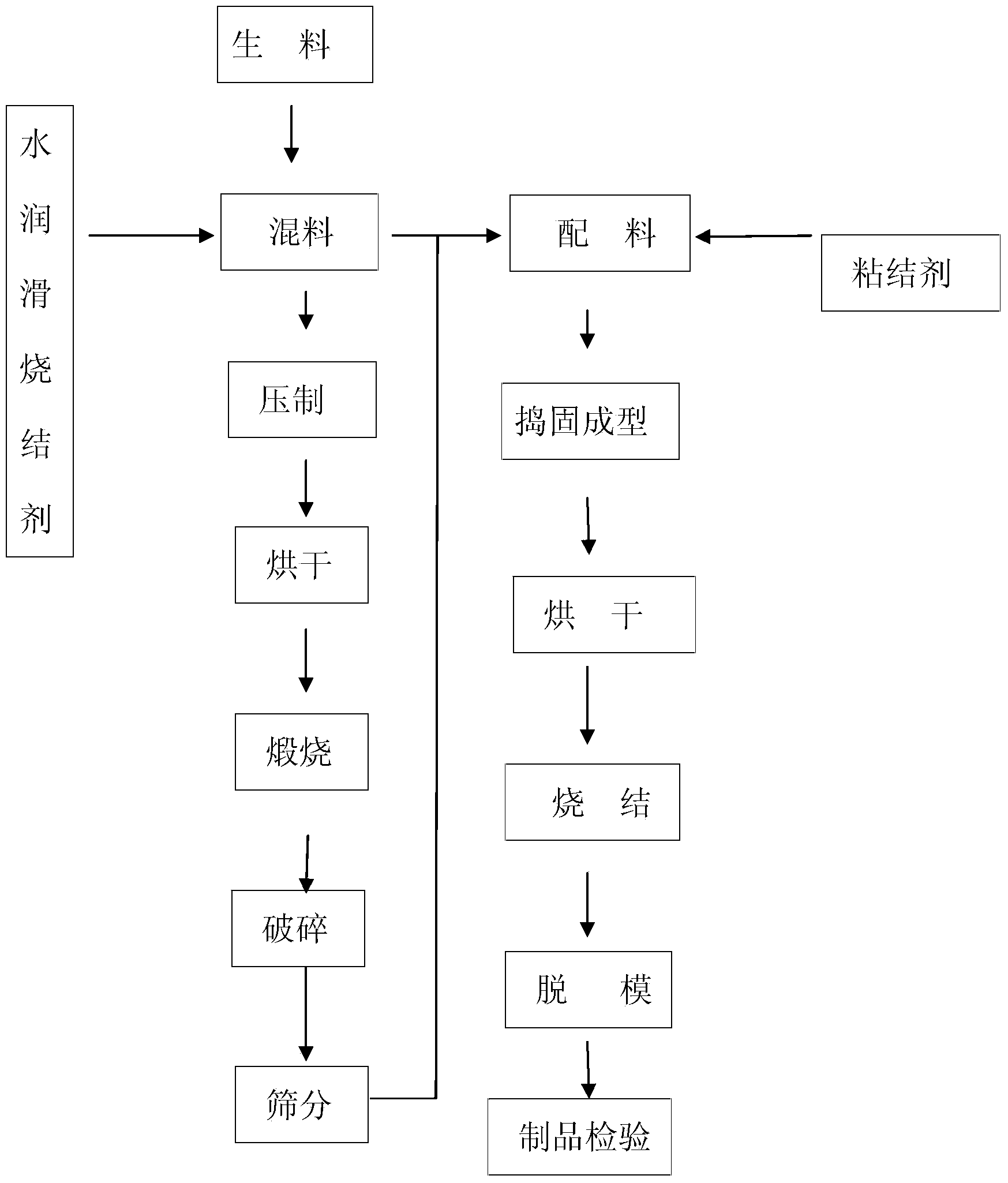

Method used

Image

Examples

Embodiment 1

[0018] 1. Preparation of beryllium oxide calcined material

[0019] Add 5kg of pure water to 50kg of beryllium oxide powder, put it in a bag, and use a cold isostatic press to perform compression molding, and control the compression pressure to 800kg (0-800kg for 1 hour, and 800kg for 30 minutes). Calcination: Put the pressed raw material into a graphite crucible and sinter it in an intermediate frequency induction furnace to increase the bulk density of the scale. The calcination process is: The calcined materials are respectively coarsely crushed and finely crushed, and then screened with sieves of three specifications. The specifications of the sieves are 5 cm, 2 cm, and less than 2 cm, respectively, to obtain granular materials in three particle size ranges, that is, particle size 5 ~10mm pellets, 2~5mm pellets and <2mm pellets.

[0020] 2. Preparation of beryllium oxide crucible

[0021] Ingredients: According to the weight ratio of 25%: 55%: 20%, three kinds of beryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com