Seal primer added polymer with formaldehyde catching function and preparation method of polymer

A technology for sealing primers and polymers, applied in the direction of polyurea/polyurethane coatings, coatings, epoxy resin coatings, etc., can solve the problem of not considering the compatibility of primers, the decline of formaldehyde absorption performance, and the decline of coating film-forming performance. and other problems, to achieve the effect of lasting formaldehyde capture and removal and obvious formaldehyde capture and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

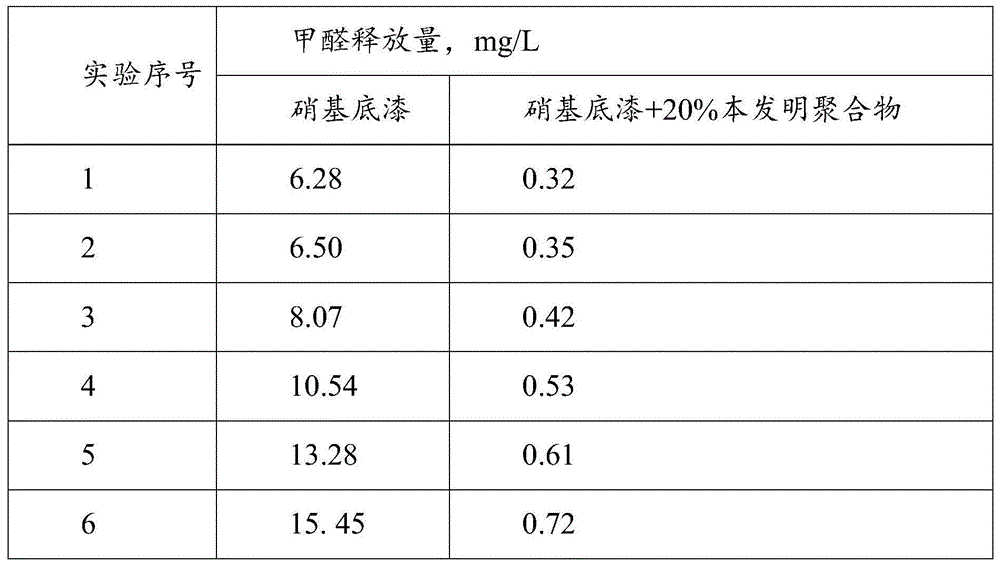

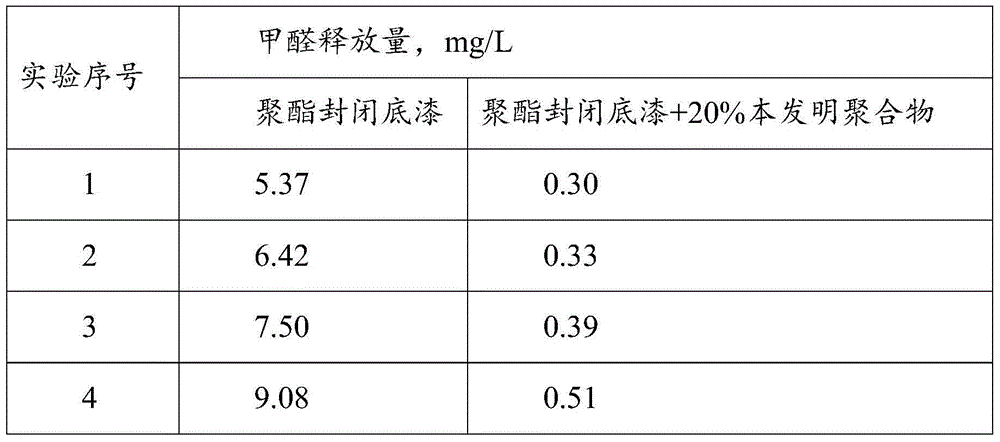

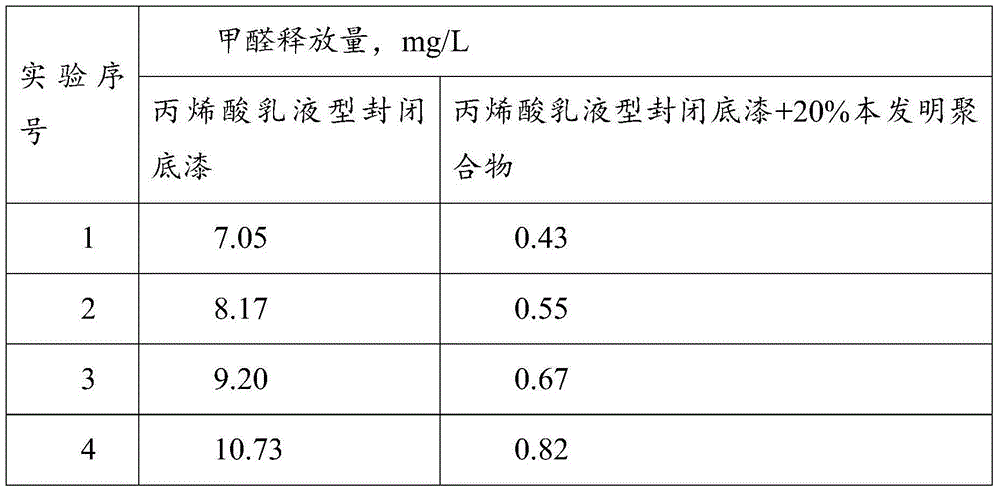

Examples

Embodiment 1

[0024] Weigh 80g of methacrylamide, 30g of butyl acrylate, 40g of methyl methacrylate, 30g of lauryl methacrylate, 2.1g of azobisisobutyronitrile, mix well and add the In the dropping funnel for use.

[0025] In a 500mL four-necked reaction flask equipped with stirring, a thermometer, a reflux condenser and a dropping funnel, add 90 g of the solvent ethylene glycol methyl ether acetate, raise the temperature to 95°C while stirring, and start to drop into the dropping funnel The mixed reaction raw material solution was kept at 95° C., and it took 2.5 hours to complete the dropwise addition of the mixed reaction raw material solution at a uniform speed. After the dropwise addition is completed, add 0.14~0.288g (reaction raw material amount=80+30+40+30=180g, 180×(0.08~0.16)=0.14~0.288g) catalyst (azodiiso Butyronitrile), under stirring, the temperature was raised to 105°C and kept at this temperature for 2.5 hours. At this time, the preparation of the resin was completed, and a ...

Embodiment 2

[0030] Weigh 60g of acryloyl hydrazine, 10g of butyl acrylate, 10g of ethyl acrylate, 30g of methyl methacrylate, 20g of lauryl acrylate, and 1.04g of benzoyl peroxide, mix them uniformly and place them in a dropping funnel for use.

[0031] In the device of Example 1, 52 g of solvent propylene glycol methyl ether acetate was added, and the temperature was raised to 90° C. under stirring, and the mixed reaction raw material solution in the dropping funnel was started to be added dropwise, and it took 3.0 hours to maintain 90° C. Add the mixed raw material solution dropwise at an even speed. After the dropwise addition is completed, add 0.104~0.208g (reaction raw material amount=60+10+10+30+20=130g, 130×(0.08~0.16)=0.104~0.208g) catalyst (benzene peroxide formyl), under stirring, the temperature was raised to 110°C, and kept at this temperature for 3.0 hours. At this time, the preparation of the resin was completed, and a transparent, light yellow viscous liquid was obtained—a ...

Embodiment 3

[0036] Weigh 100g of methacrylamide, 30g of butyl acrylate, 10g of ethyl acrylate, 30g of methyl methacrylate, 20g of styrene, 40g of isooctyl methacrylate, 3.7g of catalyst azobisisobutylcyanide, mix Evenly placed in the dropping funnel for use.

[0037] In the device of Example 1, add 138 g of isopropanol as a solvent, raise the temperature to 100°C while stirring, start to drop the mixed reaction raw material solution in the dropping funnel, and complete the mixed raw material solution in 2.0 hours while maintaining 100°C The average speed dropwise. After the dropwise addition was completed, add 0.18~0.368g catalyst (reaction raw material amount=100+30+10+30+20+40=230g, 230*(0.08~0.16)=0.18~0.368g) in the reaction flask (even Azodiisobutyrocyanide), in a stirring state, was incubated at 100°C for 3.0 hours to obtain a transparent, light yellow viscous liquid - a wood sealing primer with a formaldehyde trapping function with a solid content of 63% to add polymer 370g.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com