Flame retardant for computer motherboard

A flame retardant, motherboard technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of long-term maintenance of computer chassis, human and material damage, short-circuit of electronic devices, etc., to achieve flame-retardant effect, prevent fire, prevent fire spread effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

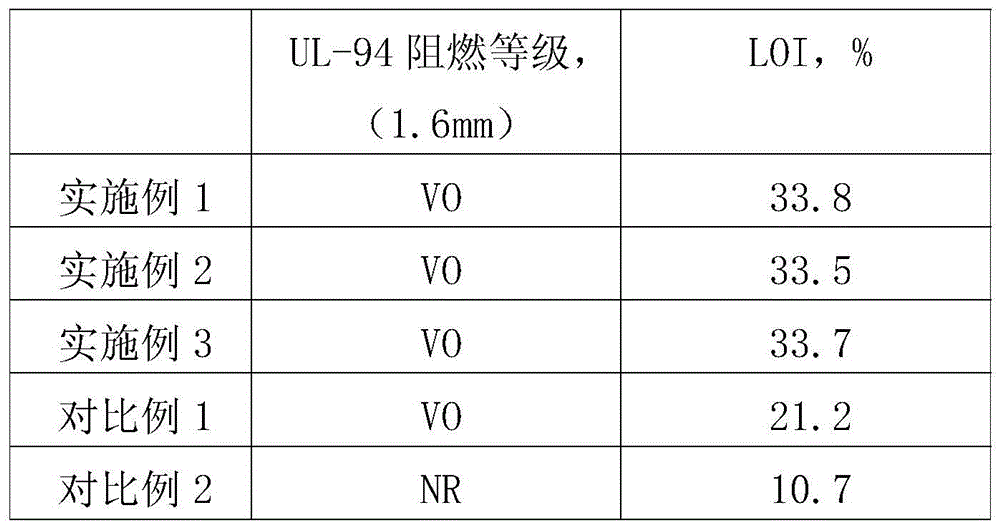

Examples

Embodiment 1

[0019] Weighing: 92kg of water, 35kg of 2-acrylic acid-2,2-dimethyl-1,3-propanediate, 33kg of 3,6-dioxa-1,8-octyldiaminetetraacetic acid, dimethacrylic acid Ethyl amino ethyl ester 28kg, (6-methoxy-4-quinolyl) (5-vinyl-1-azabicyclo[2.2.2]octane-2-yl)methanol 30kg, diethylene glycol Divinyl ether 26kg, ethoxymethylene malonate 22kg, 3-oxo-1-cyclopentane carboxylic acid 12kg, (R)-3-carboxy-2-hydroxy-N,N,N - Trimethylpropylammonium hydroxide inner salt 10 kg.

[0020] The preparation method of the flame retardant for the computer motherboard in this example: add pure water, add 2-acrylic acid-2,2-dimethyl-1,3-propanediate, 3,6-dioxa-1, 8-octyldiaminetetraacetic acid, continue to stir until uniformly dispersed, then heat to 65-80°C; slowly add diethylaminoethyl methacrylate, (6-methoxy-4-quinolyl) (5- Vinyl-1-azabicyclo[2.2.2]octane-2-yl)methanol, stir to dissolve; then add diethylene glycol divinyl ether, ethoxymethylene malonate diethyl , 3-oxo-1-cyclopentanecarboxylic acid, ...

Embodiment 2

[0022] Weighing: 92kg of water, 37kg of 2-acrylic acid-2,2-dimethyl-1,3-propanediate, 32kg of 3,6-dioxa-1,8-octyldiaminetetraacetic acid, dimethacrylic acid Ethyl amino ethyl ester 32kg, (6-methoxy-4-quinolyl) (5-vinyl-1-azabicyclo[2.2.2]octane-2-yl)methanol 32kg, diethylene glycol 25kg of divinyl ether, 20kg of diethyl ethoxymethylene malonate, 15kg of 3-oxo-1-cyclopentane carboxylic acid, (R)-3-carboxy-2-hydroxy-N,N,N - Trimethylpropylammonium hydroxide inner salt 12 kg.

[0023] The preparation method of the flame retardant for the computer motherboard of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0025] Weighing: 92kg of water, 36kg of 2-acrylic acid-2,2-dimethyl-1,3-propanediate, 35kg of 3,6-dioxa-1,8-octyldiaminetetraacetic acid, dimethacrylic acid Ethyl amino ethyl ester 30kg, (6-methoxy-4-quinolyl) (5-vinyl-1-azabicyclo[2.2.2]octane-2-yl)methanol 33kg, diethylene glycol Divinyl ether 27kg, Diethyl ethoxymethylene malonate 18kg, 3-oxo-1-cyclopentane carboxylic acid 14kg, (R)-3-carboxy-2-hydroxy-N,N,N - Trimethylpropylammonium hydroxide inner salt 13 kg.

[0026] The preparation method of the flame retardant for the computer motherboard of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com