Method for using edible mushroom residue hydrothermal carbonized product for improvement of saline-alkali soil

A technology of hydrothermal carbonization and edible fungus, which is applied in the direction of chemical instruments and methods, applications, fertilizer mixtures, etc., can solve the problems of air, soil, groundwater pollution, long improvement cycle of biological improvement methods, and high cost of engineering improvement methods. Influence, increase soil carbon sink, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Raw material preparation: the mushroom residue of Pleurotus eryngii is prepared into a mixed liquid of edible fungus residue according to the ratio of material to water 1:4;

[0018] 2) Hydrothermal carbonization: CaO was added to the mixture of Pleurotus eryngii mushroom residue for 6 hours of hydrothermal carbonization, and the hydrothermal carbonization temperature was 200°C; the amount of CaO added was 2% of that of Pleurotus eryngii mushroom residue.

[0019] 3) Solid-liquid separation: After cooling the product obtained in step 2), solid-liquid separation is carried out to obtain Ca-containing 2+ solid biochar composite materials;

[0020] 4) Saline-alkali soil improvement: will contain Ca 2+ The biochar composite material is mixed with fertilizer or organic material and applied to alkaline soil, and the application amount accounts for 2% of the soil weight.

[0021] After 30 days of planting, the aboveground biomass of sweet potato with leaves increased by 4...

Embodiment 2~6

[0024] Table 1

[0025]

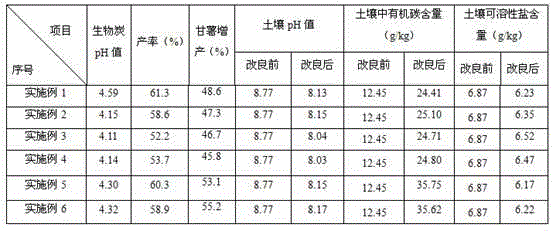

[0026] The pH value, yield of biochar in the product, and the pH value, organic carbon content, and soil soluble salt content of the soil before and after saline-alkali land improvement are shown in Table 2:

[0027] Table 2

[0028]

[0029] As can be seen from Table 2, the yield of biochar produced by hydrothermal carbonization of edible fungus slag and CaO according to the method of the present invention is higher than that obtained by hydrothermal carbonization without adding CaO. Neutralization lowers the pH of saline-alkaline soils while utilizing Ca in the product 2+ The harmful sodium in the soil is replaced by ion exchange, which reduces the salinity of the soil and has a significant improvement effect.

[0030] The raw materials in the above examples are not limited to Pleurotus eryngii and Pleurotus eryngii mushroom residues, all kinds of edible fungus residues are acceptable; the ratio of edible mushroom residues to water is prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com