Method for adjusting crystalline silica growth solid-liquid interface

A solid-liquid interface and crystalline silicon technology, which is applied in the field of solar photovoltaics, can solve problems such as quality fluctuations of crystalline silicon ingots, misalignment of solid-liquid interfaces, and uneven distribution of the thermal field of the ingot furnace, so as to increase and decrease the yield of ingots Dislocation density and effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

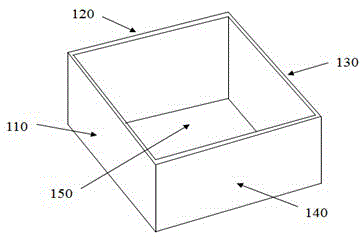

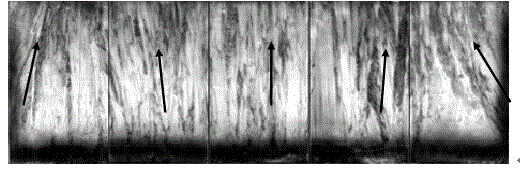

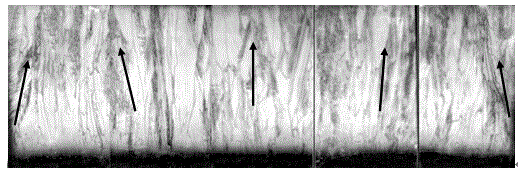

[0021] The invention discloses a method for adjusting the solid-liquid interface of crystalline silicon growth. The polysilicon ingot is grown by using a common lifting heat-insulating cage type GT450 directional solidification polysilicon furnace. The material of the crucible is high-purity quartz ceramics, and the size is 880*880*420mm. Design the crucible, side 110, side 120, side 130, side 140, and bottom 150. The thickness is designed to be 22mm, 22mm, 26mm, 22mm, 23mm in turn, and the wall thickness corresponding to side 130 is increased from 22mm to 26mm. Fill the crucible with silicon Material 485kg, successively through the melting stage → crystal growth stage → annealing stage → cooling stage. After the ingot casting is completed, the silicon ingot is longitudinally sectioned, and the longitudinal section of the five small square ingots corresponding to the center line of the silicon ingot is detected by the LIS-R1 photoluminescence tester produced by BTI Company. Af...

Embodiment 2

[0028] An improved method for adjusting the solid-liquid interface of crystalline silicon growth, specifically changing the shape, size and ingot casting process of the insulation strips on the side of the heat insulation cage in the ingot furnace: the ingot furnace includes an upper furnace body 1, a heat insulation plate 2. Side heat insulation cage 3, heater 4, graphite guard plate 5, heat exchange block 6, lower furnace body 7, heat preservation bar 8, bottom heat insulation plate 9, heat preservation device 10, ceramic crucible 11, lifting connecting rod 12, Electrode 13; Upper furnace body 1 and lower furnace body 7 are connected to form the whole furnace body, and ceramic crucible 10 is arranged in the furnace body, and crucible cover plate 11 is placed on ceramic crucible 10, and ceramic crucible 10 outside is provided with graphite guard plate 5, and ceramic crucible 10 is provided with a heat exchange block 6, the heater 4 is connected with the upper furnace body 1 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com