Detection method of volatile components in honey

A technology for volatile components and detection methods, applied in the field of testing, can solve the problems of artificial by-products, time-consuming, sugar degradation in honey, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

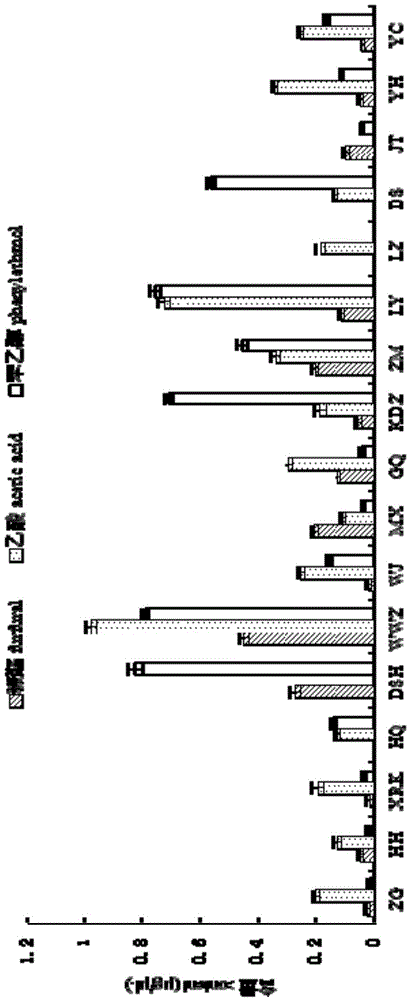

[0039] The information of the samples used in this experiment is listed in Table 1.

[0040] Table 1 Sample collection and honey source information

[0041]

[0042]

[0043] Extraction and chromatographic separation of volatile components in honey samples:

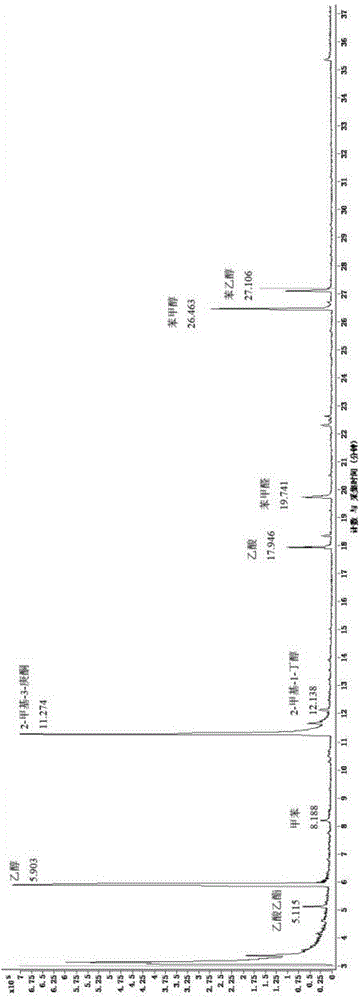

[0044](1) Conditions of headspace solid-phase microextraction Before extracting the volatile components of honey, the extraction head of the solid-phase microextraction device was first inserted into the injection hole of the gas chromatograph, and aged at 270°C for 60 minutes. Weigh 8 g of honey sample and place it in a 100 mL headspace vial, add 1 μL of internal standard substance (2-methyl-3-heptanone dissolved in n-butane, the concentration is 1.632 μg / mL) with a microsampler, and add 10 mL of saturated NaCl solution. Mix the headspace vial on a magnetic stirrer at 50°C for 30 minutes to reach the equilibrium state of the system. Insert the extraction head of the solid-phase microextraction device into the he...

Embodiment 2

[0054] The sample and chromatographic sampling methods are the same as in Example 1.

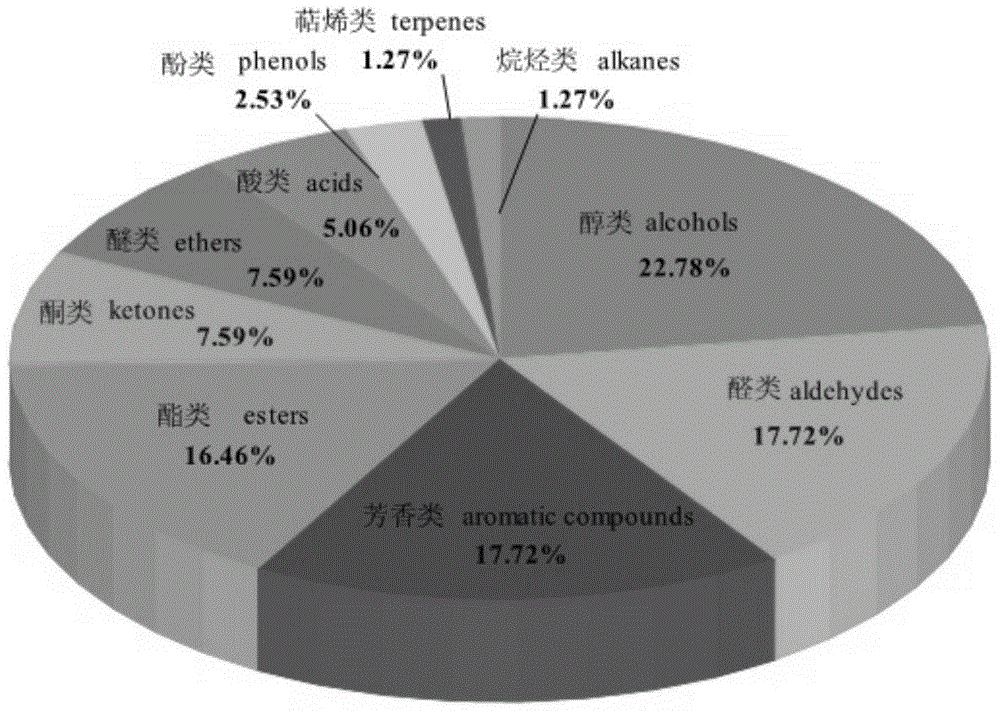

[0055] Qualitative and quantitative analysis of volatile components in honey samples:

[0056] (1) Mass spectrometry conditions: electron bombardment (EI) ion source, ion source temperature is 200°C, electron energy is 70eV, transfer line temperature is 280°C, quadrupole temperature is 150°C, solvent delay is 5min, mass scanning range is m / z 30-500.

[0057] (2) Qualitative analysis of volatile components: using the same conditions to carry out gas chromatography-mass spectrometry analysis of normal series alkanes C8-C27, using the retention time of the chromatographic peak to calculate the retention index LRI value of the corresponding target compound, and compare with www. The comparison of LRI values queried in odour.org.uk is determined to be within the range of 0-100, to achieve auxiliary characterization of compounds. The formula for calculating the LRI value of the chromatographi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com