Curable composition and cured material of the same

A composition and compound technology, applied in the direction of coating, etc., can solve the problems of weakening transparency, reducing weight, easy to change color, etc., and achieve the effects of excellent handling performance, high surface hardness, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0323] [Preparation Example 1] Preparation of Surface-Modified Silica Fine Particles (A-1)

[0324] As the silica fine particles (α) to be subjected to surface treatment, colloidal silica (silica fine particle content: 30% by mass, average particle diameter: 10-20 nm, trade name : IPA-ST, produced by Nissan Chemical Industries, Ltd.).

[0325] To a separable flask, add 100 parts of colloidal silica dispersed in isopropanol (amount includes solvent); to this separable flask, add 3 parts of gamma-methacryloxyoctyltrimethoxysilane (MOS) and 9 parts of phenyltrimethoxysilane (PhS) and mixed by stirring, further added 3.9 parts of hydrochloric acid with a concentration of 0.1825% by mass and stirred the mixture at 25° C. for 24 hours; (α) surface treatment, and then a dispersion containing the surface-modified silica fine particles (A-1) is obtained.

[0326] Loss of silane compound (herein, MOS) by hydrolysis was confirmed by gas chromatography (Model 6850; produced by Agilent...

preparation Embodiment 2

[0327] [Preparation Example 2] Surface-modified silica fine particles (A-2)

[0328] A dispersion containing surface-modified silica fine particles (A-2) was obtained in the same operation as in Preparation Example 1, except that in Preparation Example 1 for silica fine particles (α) The type and amount of each component of the surface treatment and the amount of hydrochloric acid became those shown in Table 1. The amounts added are summarized in Table 1.

[0329] [Table 1]

[0330]

[0331] The abbreviations in the table have the following meanings:

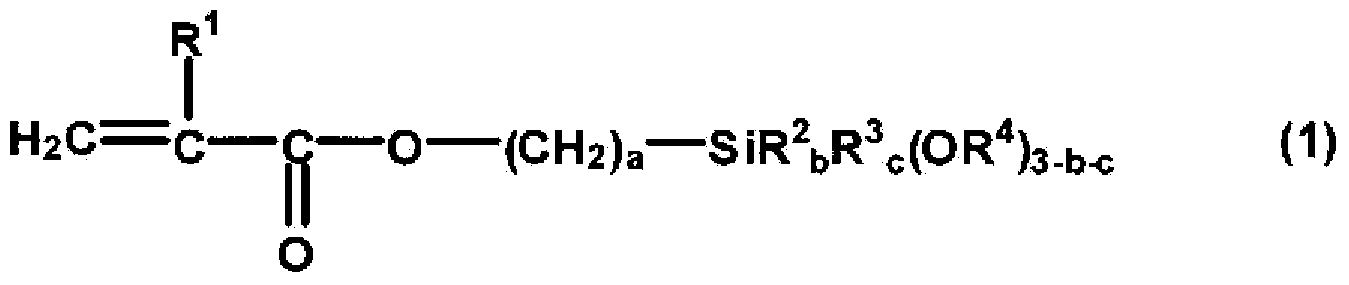

[0332] MOS, γ-methacryloxyoctyltrimethoxysilane;

[0333] MPS, γ-methacryloxypropyltrimethoxysilane;

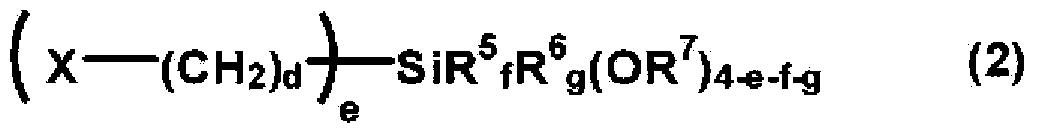

[0334] PhS, phenyltrimethoxysilane.

[0335] The unit of the values in the table is parts by mass.

Embodiment 1

[0337] Next, 24 parts by mass of trimethylolpropane triacrylate (trade name: KAYARAD, abbreviation: TMPTA, produced by NIPPON KAYAKU Co., Ltd., Tg of homopolymer: >250°C) was added to 16 parts by mass for surface treatment Silica fine particles (A-1) and mixed uniformly. Volatile components were then removed by heating at 40° C. under a reduced pressure of 100 kPa with stirring.

[0338] Subsequently, the resulting mother liquor was mixed with 60 parts by mass of 9,9-bis[4-(2-acryloyloxyethoxy)phenyl]fluorene (trade name: A-BPEF, produced by Shin-Nakamura Chemical Co., Ltd. .Production) and 6:1 mixture of benzyl acrylate (Bz-A, produced by NIHON JYORYU KOGYO CO.LTD), 0.15 parts by mass of tetramethylpiperidinyl methacrylate (trade name: FA-712HM, produced by Hitachi Chemical Co., Ltd.) and 0.15 parts by mass of 3,9-bis[2-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionyloxy]-1,1 -Dimethylethyl]-2,4,8,10-tetraoxaspiro[5.5]undecane (trade name: Sumilizer GA-80, manufactured b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com