Suppository containing high-elasticity-modulus viscose fiber and preparation method thereof

A technology of viscose fiber and high elasticity, which is applied in the field of medicine, and can solve the problems that the expansion carrier cannot effectively expand, the drug cannot effectively reach the focus, and is not conducive to the treatment of gynecological diseases, so as to improve compliance, effectively expand, and the preparation method is simple and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 High elastic modulus viscose fiber

[0039] High elastic modulus viscose fiber is prepared by processing raw fiber including the following parts by weight:

[0040] Cotton fiber 10 Rose fiber 5 Silk 40 Acetate fiber 8

[0041] Preparation:

[0042] a. Mix cotton fiber, rose fiber, silk, and acetate fiber to obtain composite cellulose pulp;

[0043] b. Immerse the composite cellulose pulp in a 10% NaOH solution at 52°C for 30 minutes to obtain alkali cellulose;

[0044] c. After the alkali cellulose is squeezed and pulverized by a press, it undergoes a yellowing reaction with carbon disulfide to generate cellulose xanthate, the temperature of the yellowing reaction is 25° C., and the yellowing time is 100 min;

[0045] d. Dissolve the cellulose xanthate in a 10% NaOH solution for 60 minutes to obtain a viscose solution;

[0046] e. The viscose solution is matured at 20°C for 30 min, and defoamed and filtered during the maturation process to obtain a spinning solution;

[004...

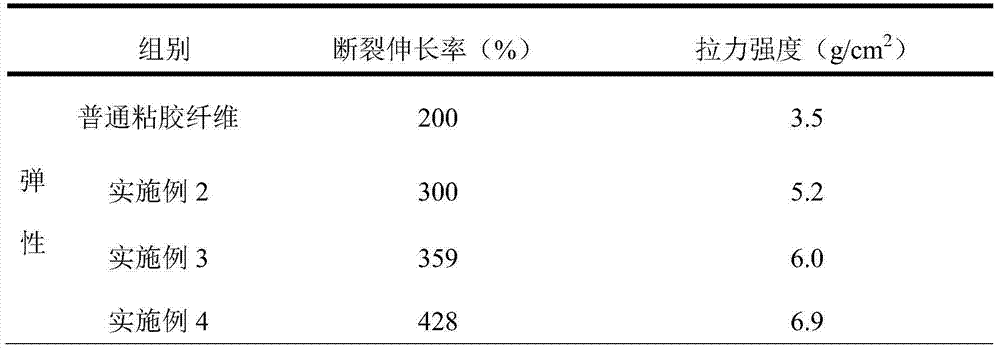

Embodiment 2

[0048] Example 2 High elastic modulus viscose fiber

[0049] High elastic modulus viscose fiber is prepared by processing raw fiber including the following parts by weight:

[0050] Cotton fiber 30 Rose fiber 25 Silk 15 Acetate fiber 3

[0051] Preparation method: According to the method of Example 1, a high elastic modulus viscose fiber was prepared.

Embodiment 3

[0052] Example 3 High elastic modulus viscose fiber

[0053] High elastic modulus viscose fiber is prepared by processing raw fiber including the following parts by weight:

[0054] Cotton fiber 20 Rose fiber 15 Silk 30 Acetate fiber 5

[0055] Carbon Fiber 2 Ethylene Butyl Acrylate 2

[0056] Preparation:

[0057] a. Blend cotton fiber, rose fiber, silk, acetate fiber, and carbon fiber to obtain composite cellulose pulp;

[0058] b. Immerse the composite cellulose pulp in a 10% NaOH solution at 52°C for 30 minutes to obtain alkali cellulose;

[0059] c. Add ethylene butyl acrylate to the alkali cellulose, mix it evenly, press and pulverize by a press, and then undergo a yellowing reaction with carbon disulfide to produce cellulose xanthate. The temperature of the yellowing reaction is 25°C, The yellowing time is 100min;

[0060] d. Dissolve the cellulose xanthate in a 10% NaOH solution for 60 minutes to obtain a viscose solution;

[0061] e. The viscose solution is matured at 20°C for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com