Full-automatic quartz sand production line

A fully automatic, production-line technology, applied in solid separation, separation of solids from solids by gas flow, chemical instruments and methods, etc., can solve the problems of low purity of quartz sand and cumbersome process, and achieve a wide range of applications and less impurities. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

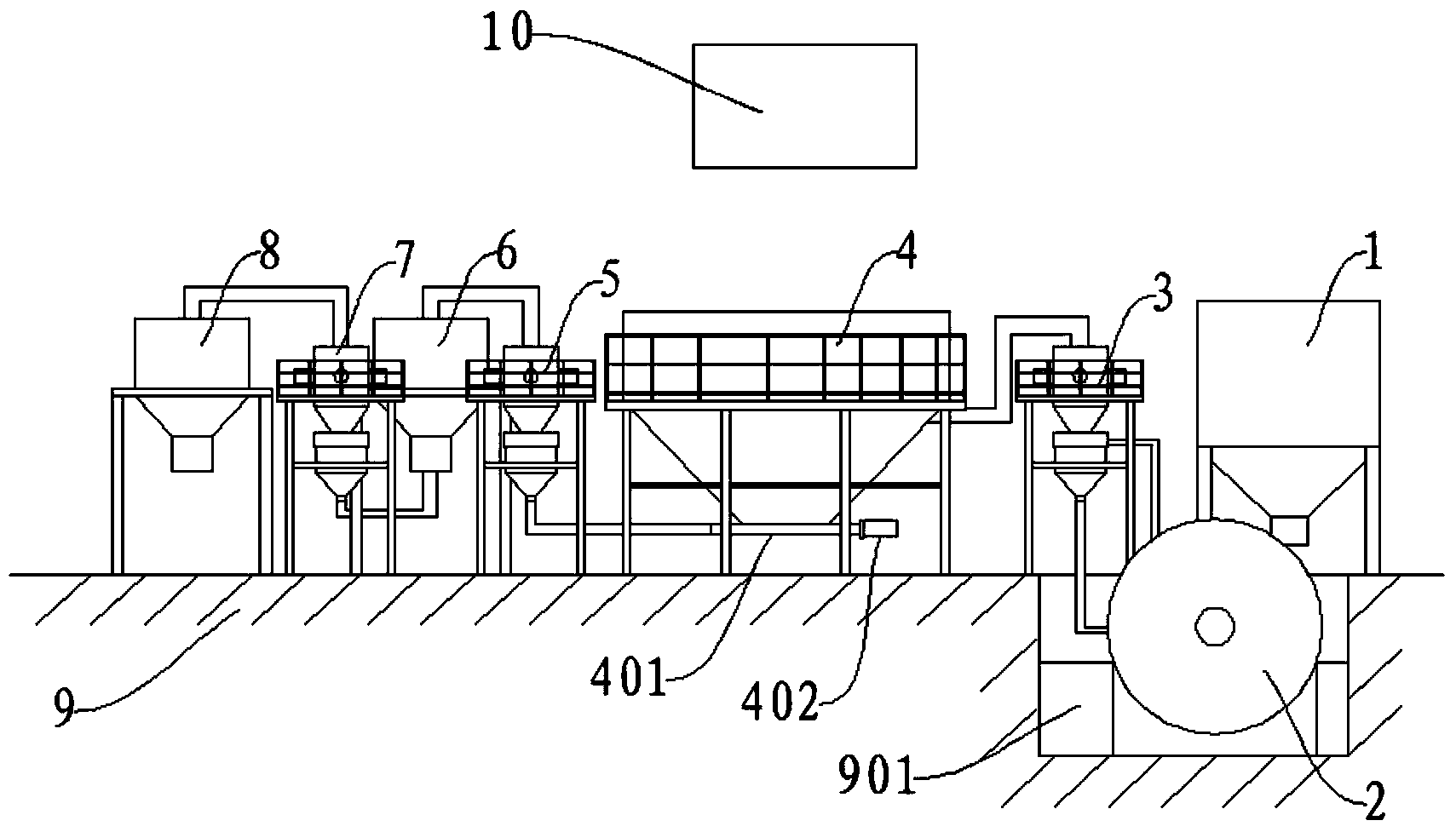

[0013] Referring to the accompanying drawings, a fully automatic production line for quartz sand, including an installation floor 9, is characterized in that: the installation floor 9 is sequentially installed with a storage bin 1, a multifunctional air classifier-3, a pulse vacuum cleaner-4, multiple Functional air classifier two 5, pulse vacuum cleaner two 6, multifunctional air classifier three 7 and pulse vacuum cleaner three 8, the installation ground 9 between the storage bin 1 and the multifunctional air classifier one 3 is provided with pits 901, the pit 901 is provided with a ball mill 2, the outlet of the ball mill 2 is connected to the multifunctional air classifier-3 through a pipeline, and the multifunctional air classifier-3 is connected to the pulse vacuum cleaner through a pipeline One 4, the bottom of the pulse vacuum cleaner one 4 is provided with a conveying device, the multifunctional air classifier two 5, the pulse vacuum cleaner two 6, the multifunctional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com