Preparation method of dual-layer glue-free type double-face flexible copper-clad plate

A flexible copper-clad laminate and double-sided technology is applied in the field of preparation of two-layer adhesive-free double-sided flexible copper-clad laminates, which can solve the problems of dimensional stability, heat resistance, and solder resistance of double-sided flexible copper-clad laminates. The production process of double-sided flexible copper clad laminates is complicated, and the bonding strength is difficult to improve, so as to achieve the effect of simplifying the overall structure and production process, high flexibility, and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

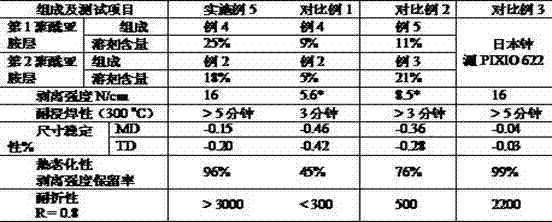

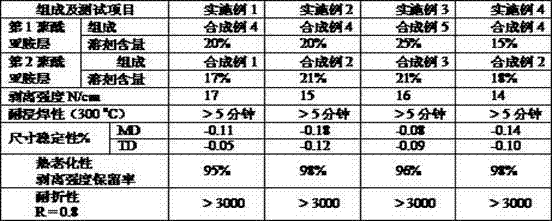

Examples

Synthetic example 1

[0029][Synthesis Example 1]: Under nitrogen atmosphere, add 200.2 g of 4,4'-ODA and 212.2 g of 4,4'-diaminobenzophenone into 4132 g of DMAc solvent, stir until completely dissolved; then 620.4 g of s-ODPA was added in three batches, followed by stirring for about 24 h to prepare a polyimide precursor solution with a solid content of 20 wt% and a viscosity of 1500 mPa·s.

Synthetic example 2

[0030] [Synthesis Example 2]: Under a nitrogen atmosphere, add 300.3 g of 4,4'-ODA and 106.1 g of 4,4'-diaminobenzophenone into 4119 g of DMAc solvent, and stir until completely dissolved; then 542.9 g of s-ODPA and 80.56 g of s-BTDA were added in three batches, followed by stirring for about 24 h to prepare a polyimide precursor solution with a solid content of 20 wt% and a viscosity of 3750 mPa·s.

Synthetic example 3

[0031] [Synthesis Example 3]: Under a nitrogen atmosphere, add 396.5 g of 4,4'-MDA into 4068 g of NMP solvent and stir until completely dissolved; then add 310.2 g of s-ODPA and 310.2 g of a-ODPA, followed by stirring for about 24 h to prepare a polyimide precursor solution with a solid content of 20 wt% and a viscosity of 4200 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com