Method for synthesizing ethyl p-hydroxybenzoate through catalysis of modified metal oxide type solid super acid

A technology of ethyl hydroxybenzoate and p-hydroxybenzoic acid, which is applied in the field of catalytic synthesis of ethyl p-hydroxybenzoate by modified metal oxide solid superacids, and can solve the problems of lack of green synthesis technology of ethyl p-hydroxybenzoate , achieve the effect of maintaining high activity for repeated use, high economic and social benefits, and remarkable catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

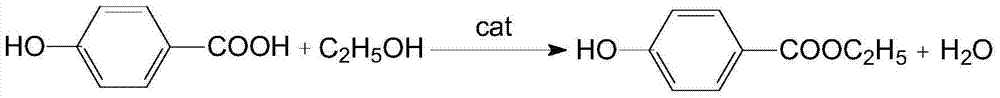

Method used

Image

Examples

Embodiment 1

[0017] Preparation of modified metal oxide solid superacid:

[0018] ZrOCl 2 ·8H 2 O is dissolved in deionized water to prepare a solution with a certain concentration. First, add quantitatively calculated boric acid, stir and dissolve, then add a certain proportion of ammonium metatungstate, stir and dissolve, and mix the prepared solution with 6mol / l ammonia water gradually under stirring conditions. Add dropwise to a certain amount of ammonia solution with pH=9, control the pH value of the whole dropping process to be constant at 9, continue to stir for a certain period of time after the dropwise addition, leave it to age at room temperature, filter and wash with deionized water until it cannot be detected Cl - ion, dried at 120°C for 12h, and then roasted at 700°C for 3h in an atmosphere-protected box furnace to obtain a modified metal oxide solid superacid WO 3 / B 2 o 3 -ZrO 2 ,stand-by.

[0019] Synthesis of ethyl p-hydroxybenzoate:

[0020] Add 3.45g p-hydroxybe...

Embodiment 2

[0025] The difference between embodiment 2 and embodiment 1 is: add 3.45g p-hydroxybenzoic acid, 10.5ml dehydrated alcohol and 0.58g modified metal oxide type solid superacid WO in the reaction vessel 3 / B 2 o 3 -ZrO 2 , heating to raise the temperature, and carry out the esterification reaction under the condition of reflux temperature. After the reaction, the solid superacid catalyst was separated and recovered by filtration, and the excess ethanol was removed from the filtrate by rotary evaporation to obtain the product ethyl p-hydroxybenzoate with a yield of 91.8%.

[0026] The recovered solid superacid catalyst can be recycled after being regenerated and vacuum-dried.

Embodiment 3

[0028] The difference between embodiment 3 and embodiment 1 is: add 3.45g p-hydroxybenzoic acid, 12.0ml dehydrated alcohol and 0.49g modified metal oxide type solid superacid WO in the reaction vessel 3 / B 2 o 3 -ZrO 2 , heating to raise the temperature, and carry out the esterification reaction under the condition of reflux temperature. After the reaction, the solid superacid catalyst was separated and recovered by filtration, and excess ethanol was removed from the filtrate by rotary evaporation to obtain the product ethyl p-hydroxybenzoate with a yield of 91.0%.

[0029] The recovered solid superacid catalyst can be recycled after being regenerated and vacuum-dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com