Enhanced-type composite adhesive of lithium ion battery, preparation method and application thereof

A technology for composite binders and lithium-ion batteries, which is applied in the direction of non-polymer binder additives, binder types, cellulose binders, etc., can solve problems that do not consider the binding force of binders and active materials, and the environment. Influence and other issues, to achieve the effect of improving cycle stability, preventing volume expansion, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

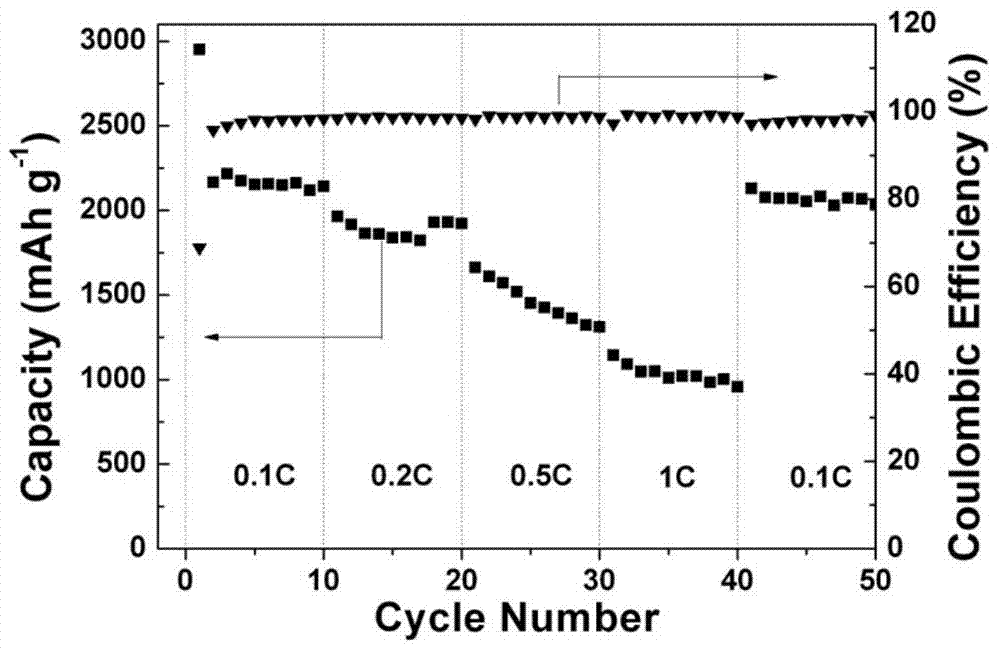

Embodiment 1

[0026] The lithium-ion battery-enhanced composite adhesive in this embodiment is composed of 0.01 g of carboxyl-functionalized carbon nanotubes and 0.1 g of sodium alginate.

[0027] The preparation method of carboxyl functionalized carbon nanotubes in this embodiment comprises the following steps:

[0028] (1) Prepare 120mL of mixed solution of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1;

[0029] (2) Add 3g of carbon nanotubes to the mixture, ultrasonicate for 8 hours at a frequency of 22kHz and a power of 500W, then stir and reflux at 120°C for 2 hours, remove the supernatant after centrifuging the obtained solution, and add deionized water to shake After uniformity, centrifuge again, repeat the operation until the pH value of the supernatant is greater than 6.5, and vacuum-dry at 120°C to obtain the final product.

[0030] The preparation method of lithium-ion battery-enhanced ...

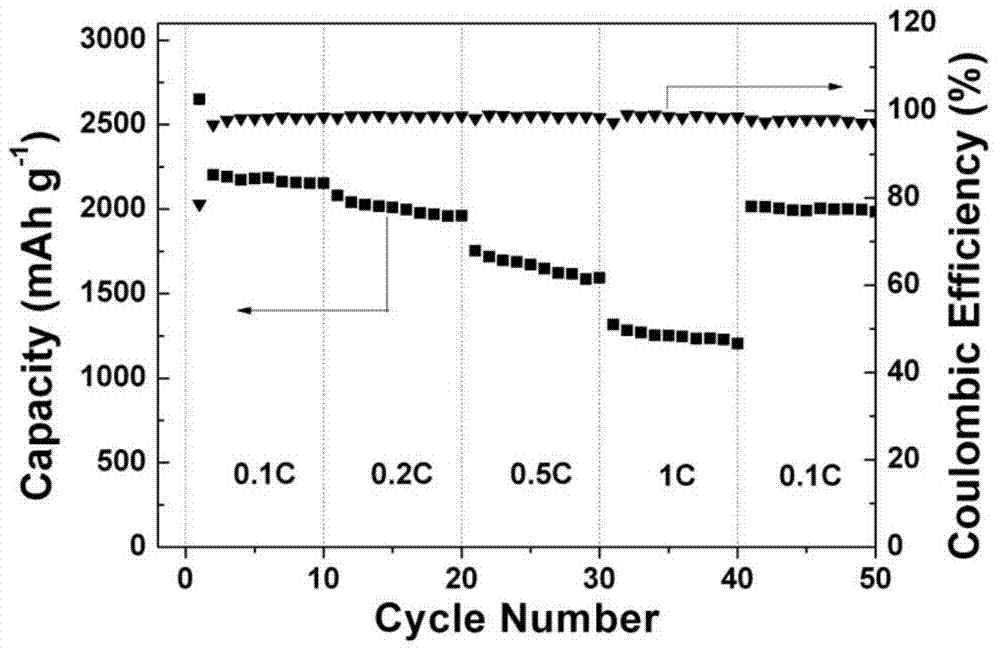

Embodiment 2

[0038] The lithium-ion battery-enhanced composite adhesive in this example is composed of 0.1 g of carboxy functionalized carbon nanotubes and 0.1 g of carboxymethyl chitosan.

[0039] The preparation method of carboxyl functionalized carbon nanotubes in this embodiment comprises the following steps:

[0040] (1) Prepare 120mL of mixed solution of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:2;

[0041] (2) Add 3g of carbon nanotubes to the mixture, ultrasonicate for 6 hours at a frequency of 22kHz and a power of 500W, then stir and reflux at 60°C for 12 hours, remove the supernatant after the obtained solution is centrifuged, and add deionized water to shake After uniformity, centrifuge again, repeat the operation until the pH value of the supernatant is greater than 6.5, and vacuum-dry at 120°C to obtain the final product.

[0042] The preparation method of lithium-ion battery-enhan...

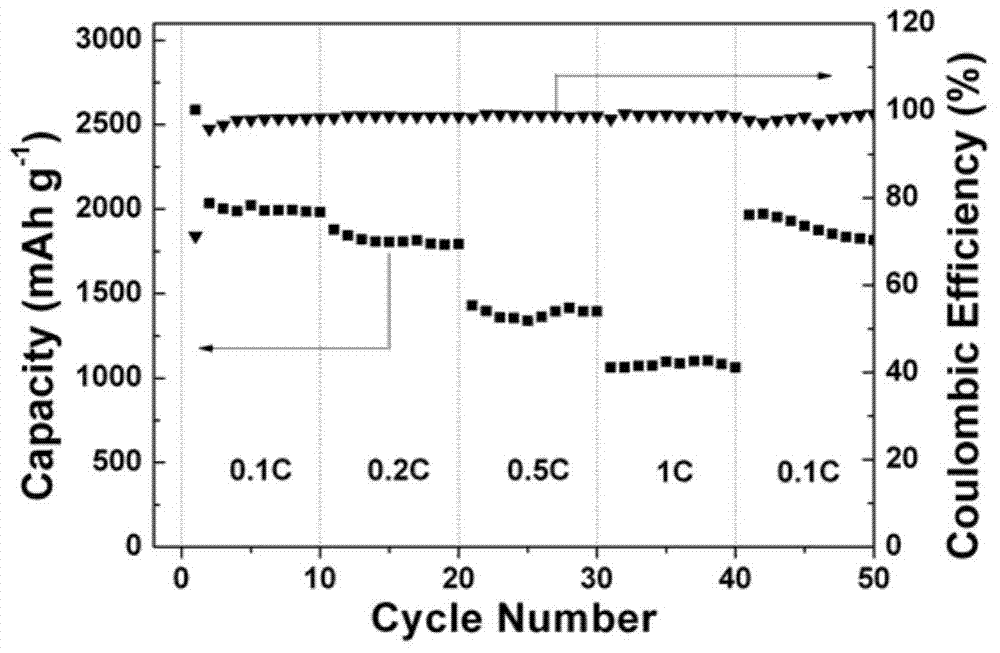

Embodiment 3

[0050] The lithium-ion battery-enhanced composite binder in this embodiment is composed of 0.05 g of carboxyl-functionalized carbon nanotubes and 0.1 g of sodium carboxymethyl cellulose.

[0051] The preparation method of carboxyl functionalized carbon nanotubes in this embodiment comprises the following steps:

[0052] (1) Prepare 120mL of mixed solution of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 2:1;

[0053] (2) Add 2g of carbon nanotubes to the mixture, ultrasonicate for 24 hours at a frequency of 22kHz and a power of 500W, then stir and reflux at 80°C for 10 hours, remove the supernatant after the obtained solution is centrifuged, and add deionized water to shake After uniformity, centrifuge again, repeat the operation until the pH value of the supernatant is greater than 6.5, and vacuum-dry at 120°C to obtain the final product.

[0054] The preparation method of lithium-ion b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Inverse specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com