Linear compressor and piston thereof

A linear compressor and piston technology, applied in machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of reducing the performance of the linear compressor, damage to the suction valve plate 22, damage to the piston head 23, etc. , to avoid skew, reduce quality and reduce defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

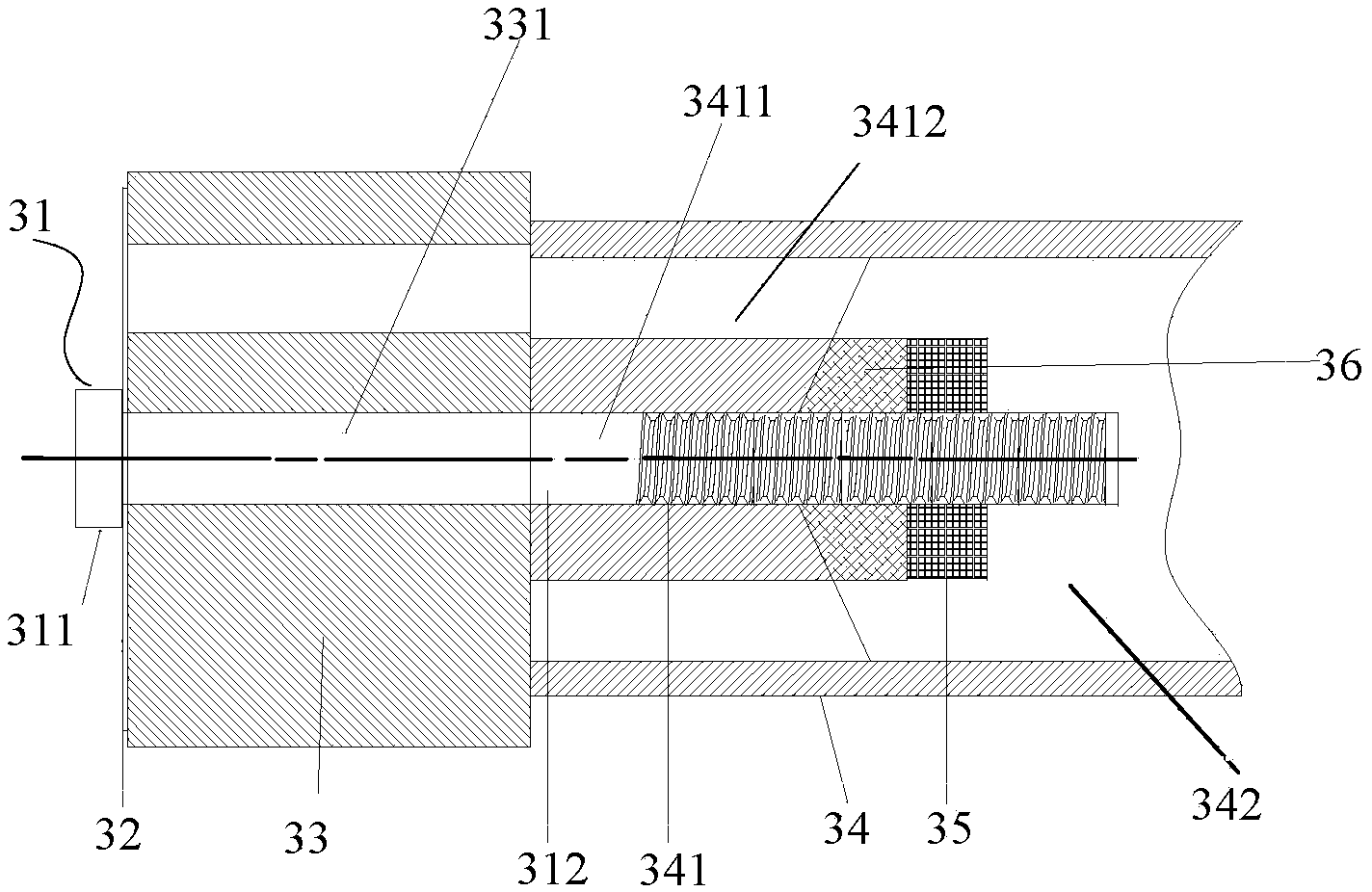

[0061] Such as image 3 Shown is a schematic diagram of the piston of the linear compressor of the present invention, the piston includes a piston head 33 and a piston rod 34 , and the piston head 33 and the piston rod 34 are fixedly connected by bolts 31 and nuts 35 .

[0062] The bolt 31 includes a bolt head 311 and a screw rod 312 . A suction valve plate 32 is arranged between the bolt head 311 and the piston head 33 .

[0063] The center of the piston head 33 defines a through positioning hole 331 . The part of the piston rod 34 close to the piston head 33 is a solid section 341 , and the rest is a hollow section 342 . The center of the solid section 341 defines a through positioning through hole 3411 , the positioning through hole 331 of the piston head 33 and the positioning through hole 3411 of the solid section 341 are passed through by the screw rod 312 . Such positioning through-hole technology facilitates processing and improves production efficiency. The solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com