A kind of solid oxide fuel cell and its preparation method

A solid oxide and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems affecting battery performance, large concentration polarization, unsuitable for preparation, etc., and achieve excellent mechanical strength and reduced transport resistance Small, fine microstructure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

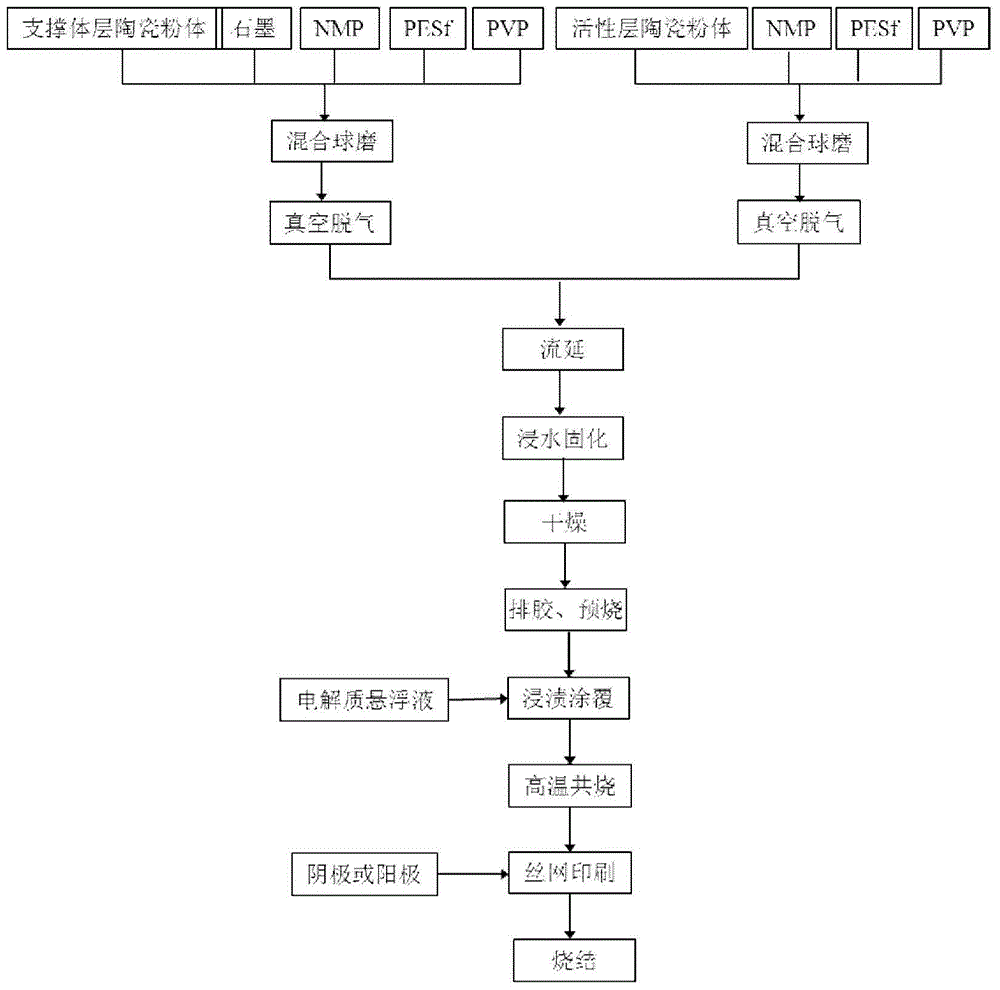

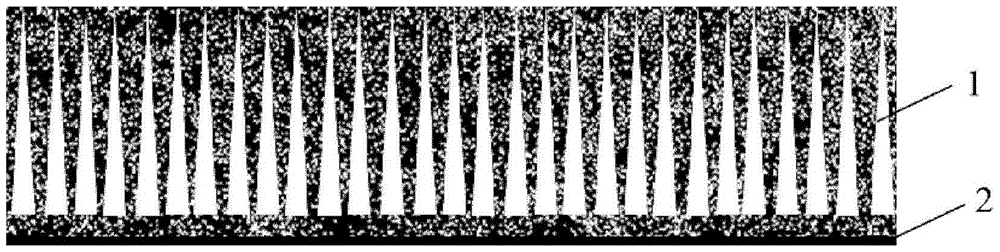

[0051] In a specific embodiment, the steps of the method for preparing a solid oxide fuel cell with a flat straight-pore structural support of the present invention are as follows:

[0052] (1) Dissolve 4-10% binder polyethersulfone (PESf) and 1-2% dispersant polyvinylpyrrolidone (PVP) in 20-38% organic solvent 1-methyl- In 2-pyrrolidone (NMP), make a uniform organic solution, then add ceramic powder and pore-forming agent to the organic solution, and ball mill to prepare a stable support layer slurry 1 with a solid content of 50-75%, wherein the ceramic powder The body accounts for 70-95% of the total solids; a similar method is used to prepare the battery anode (or cathode) active layer slurry 2, wherein the mass fraction of polyethersulfone is 4-12%, polyvinylpyrrolidone is 1-3%, 1- The solid content of the anode (or cathode) active layer material powder is 45-75%.

[0053] (2) vacuum degassing slurry 1 and slurry 2 for 5-30 minutes;

[0054] (3) On the polyester film car...

Embodiment 1

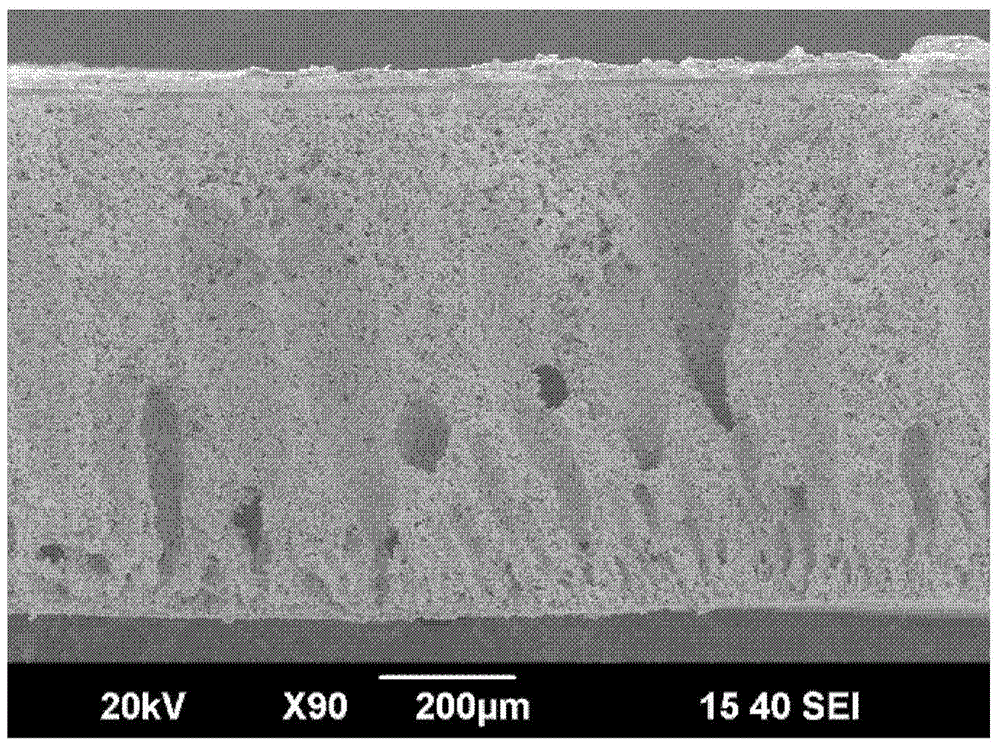

[0068] Example 1: Solid Oxide Fuel Cell Supported by Flat Straight Hole Structure Anode

[0069] The electronic conductive phase of the anode support layer adopts domestic NiO powder, its particle size D50=1μm, and the ion conductive phase adopts domestic Zr 0.84 Y 0.16 o 1.92 (YSZ), its particle size D50 = 0.75 μm; the electronically conductive phase NiO of the anode active layer is obtained by decomposing basic nickel carbonate at 700 ° C, its particle size D50 = 0.5 μm, and the ion conductive phase also uses domestic Zr 0.84 Y 0.16 o 1.92 (YSZ), the particle size D50=0.75 μm;

[0070] Mix the above-mentioned NiO and YSZ powders for the anode support layer at a volume ratio of 56:44, mix them uniformly by ball milling in ethanol for 6 hours, and obtain the NiO-YSZ mixed powder after drying; at the same time prepare the mixed powder for the anode active layer, wherein NiO and YSZ The powder volume ratio is 47:53;

[0071] Weigh 160g of anode support layer mixed powder, ...

Embodiment 2

[0078] Example 2: Flat-type straight-hole structure cathode-supported solid oxide fuel cell

[0079] According to (La 0.8 Sr 0.2 ) 0.95 MnO 3-δ (LSM) stoichiometric ratio accurately weighed La 2 o 3 , SrCO 3 and MnO 2 , the powders were mixed and ball milled with ethanol as the medium for 24 hours; after drying, they were calcined at 1100°C for 10 hours to obtain perovskite phase LSM powders with a particle size of D50=1.5 μm, which were used as the electronically conductive phase of the cathode support layer and the cathode active layer Powder. The cathode support layer and the cathode active layer ion-conducting phase powder use domestic Zr 0.84 Y 0.16 o 1.92 (YSZ), particle size D50 = 0.75 μm.

[0080] Mix the above-mentioned cathode support layer LSM and YSZ powders in a volume ratio of 50:50, mix them uniformly by ball milling in ethanol for 6 hours, and obtain the LSM-YSZ mixed powder after drying; prepare the mixed powder of the cathode active layer at the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com