Thickened oil cold-water-injected fat-soluble dissolving nano oil-displacing agent as well as preparation method and application of nano oil-displacing agent

A fat-soluble, oil-displacing agent technology, applied in chemical instruments and methods, earthwork drilling, mechanical equipment, etc., can solve the problems of high wax content, low pressure at the suction port, and reduced oil flow channel, etc. Strong solubility, reduce the viscosity of heavy oil, reduce the effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1 of the present invention discloses a heavy oil injection cold water fat-soluble dissolving nano-oil displacement agent HCD 1 , The technical solutions adopted are as follows:

[0083] A heavy oil injection cold water fat-soluble dissolving nano-oil displacement agent HCD 1 , Consists of the following components in weight percentage: 18% isoamyl butyrate, 18% isooctyl acrylate, 16% benzyl acetate, 10% isobutyl isobutyrate, 8% 2-ethylhexanol, Decanol 7%, methyl isobutyl methanol 6%, ethylene glycol butyl ether acetate 6%, butyl butyrate 6%, APG12145%. Among them, APG1214 has strong salt resistance, is not affected by temperature, and has good biodegradability. It can significantly reduce surface tension when combined with alcohol. It can dissolve paraffin, asphalt, and gum, especially at low temperature. It has good solubility and good viscosity reduction effect.

[0084] The heavy oil obtained in this example is cold-water-injected fat-soluble dissolving nano-oil...

Embodiment 2

[0088] Embodiment 2 of the present invention discloses a heavy oil injection cold water fat-soluble dissolving nano-oil displacing agent HCD 2 , The technical solutions adopted are as follows:

[0089] A heavy oil injection cold water fat-soluble dissolving nano-oil displacement agent HCD 2 , Consists of the following components in weight percentage: 9% isoamyl butyrate, 9% isooctyl acrylate, 9% benzyl acetate, 5% methyl isobutyl methanol, ethylene glycol butyl ether acetate 5 %, isobutyl isobutyrate 8%, butyl butyrate 5%, isoamyl acetate 5%, dioctyl phthalate 5%, tributyl phosphate 2%, methyl methacrylate 2%, 2-ethylhexanol 3%, decanol 5%, APG12148%, pentanol 5%, neopentyl alcohol 5%, 2-heptanol 5%, cyclohexanol 5%.

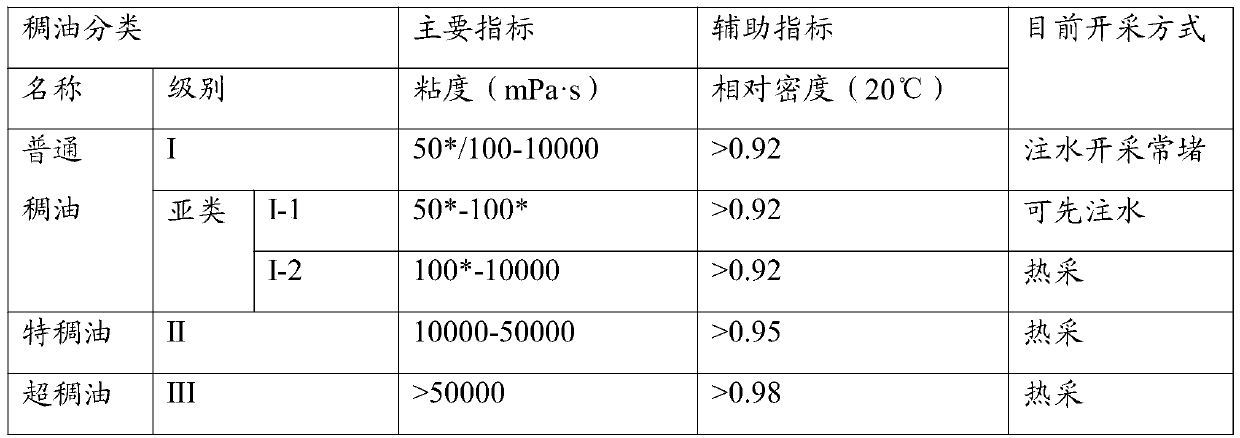

[0090] This embodiment is suitable for the thin oilization of super heavy oil with a viscosity of 50000 mPa.s-100000 mPa.s, which can increase the seepage rate of heavy oil in the formation and increase the pipeline oil delivery speed.

[0091] Under normal temperatur...

Embodiment 3

[0093] Example 3 of the present invention discloses a heavy oil injection cold water fat-soluble dissolving nano-oil displacing agent HCD 3 , The technical solutions adopted are as follows:

[0094] A heavy oil injection cold water fat-soluble dissolving nano-oil displacement agent HCD 3 , Consisting of the following components in weight percentage: 4% isoamyl butyrate, 4% isooctyl acrylate, 4% phenyl acetate, 7% methyl isobutyl methanol, ethylene glycol butyl ether acetate 7 %, isobutyl isobutyrate 8%, butyl butyrate 7%, isoamyl acetate 5%, dioctyl phthalate 5%, tributyl phosphate 5%, methyl methacrylate 5%, Dioctyl adipate 3%, dioctyl phthalate 3%, dioctyl sebacate 3%, pentanol 5%, neopentyl alcohol 5%, 2-heptanol 5%, cyclohexanol 5%, APG081010%, of which APG0810 has good foam performance, good dissolved rock performance, strong acid sensitivity, water sensitivity, and salt sensitivity.

[0095] Embodiment 3 of the present invention is suitable for the thin oilization of extra-h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com