High-stability high-permeability two-phase composite oxygen separation membrane and preparation method thereof

A high-permeability, high-stability technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as limiting the practical use of chromium-based materials, unstable dual-phase composite membrane structure, and membrane failure , to achieve good high oxygen permeability, good long-term stability, and reduced transport resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a high-stability and high-permeability dual-phase composite oxygen separation membrane, comprising the following steps:

[0037] A) One-step synthesis of Ce by combustion method 0.8 SM 0.2 o 2-δ –La 0.9 Sr 0.1 FeO 3-δ Two-phase composite powder, δ is the concentration of oxygen vacancies;

[0038] Mixing the two-phase composite powder with an organic solvent to obtain a two-phase composite powder slurry;

[0039] B) mixing the pore-forming agent with an organic solvent to obtain a pore-forming agent slurry;

[0040] C) sequentially casting the two-phase composite powder slurry and the pore-forming agent slurry onto the surface of the carrier tape to obtain a casting layer compounded on the surface of the carrier tape;

[0041] curing and drying the casting layer compounded on the surface of the carrier tape to obtain a green body;

[0042] D) Sintering the green body to obtain a high-stability and high-permeability d...

Embodiment 1

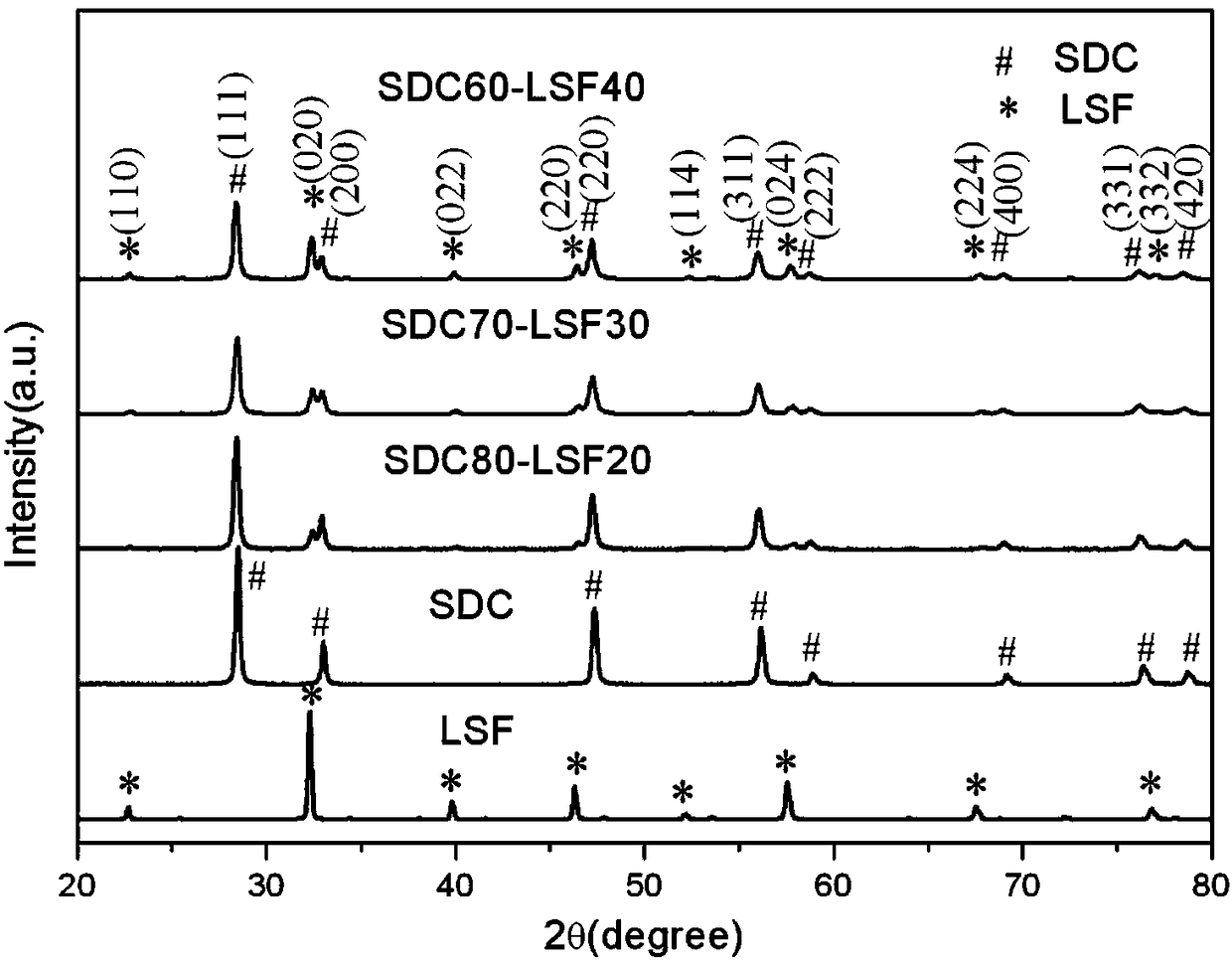

[0077] Ce with different volume ratios of 6:4, 7:3 and 8:2 0.8 SM 0.2 o 2-δ –La 0.9 Sr 0.1 FeO 3-δ (SDC–LSF) dual-phase composite powders were synthesized in one step by combustion method. Specifically, La 2 o 3 , SrCO 3 , Fe(NO 3 ) 3 9H 2 O, Sm 2 o 3 and Ce(NO 3 ) 3 ·6H 2 O was dissolved in the nitric acid solution in the corresponding stoichiometric ratio, and then during the stirring process, citric acid was added to the solution in an amount of the substance with a molar ratio of 1:1.5 to the total metal ions, and the NH 3 ·H 2 O adjust the pH of the solution to 7-8. The solution complexed by citric acid is placed on an electric furnace to heat and evaporate water to form a gel, and then the gel is burned to form an initial powder. The obtained initial powder was sintered at 1000°C for 3h in the air atmosphere of a box-type resistance furnace to obtain a dual-phase composite powder. Ce with different volume ratios of 6:4, 7:3 and 8:2 0.8 SM 0.2 o 2-δ ...

Embodiment 2

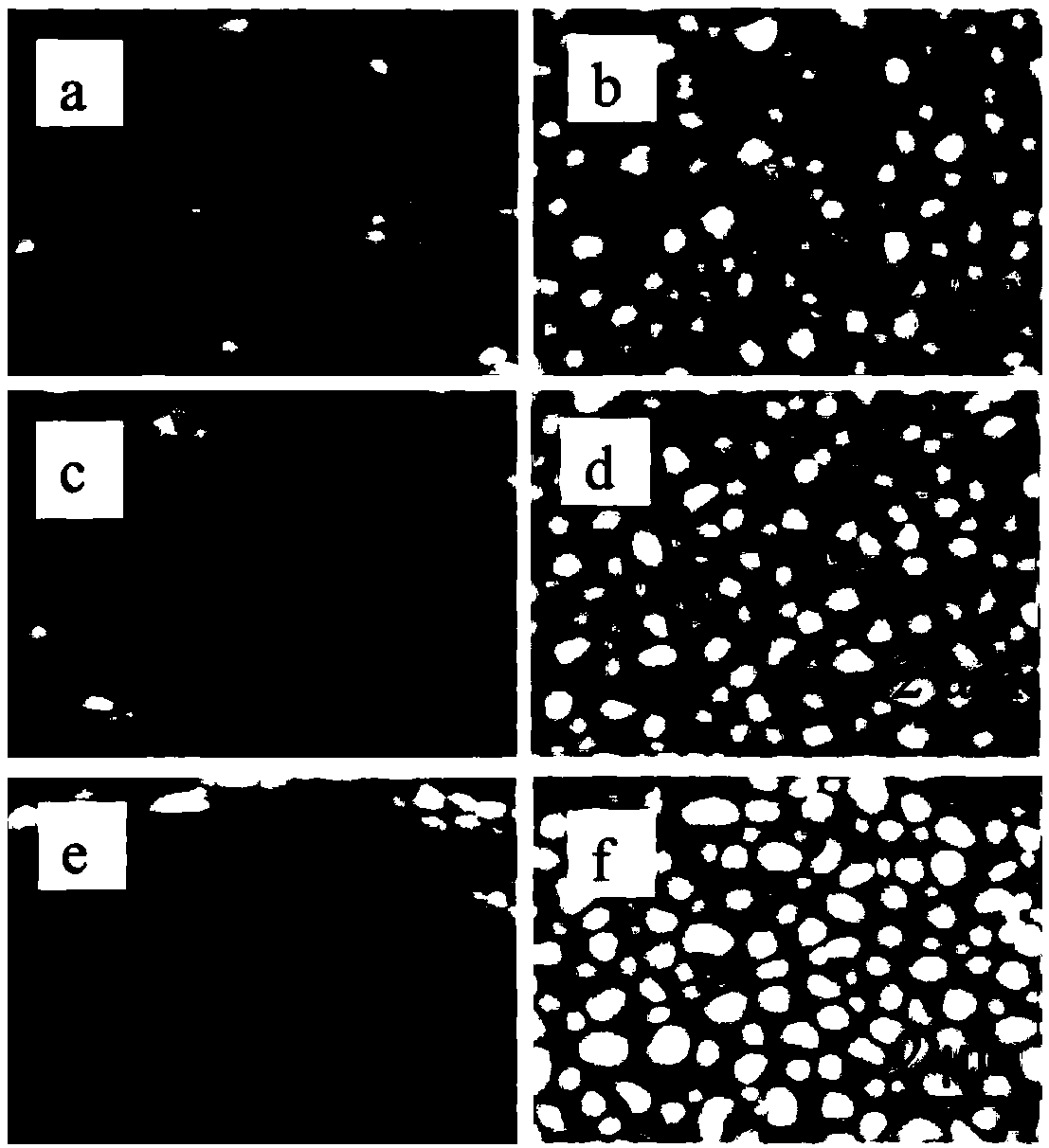

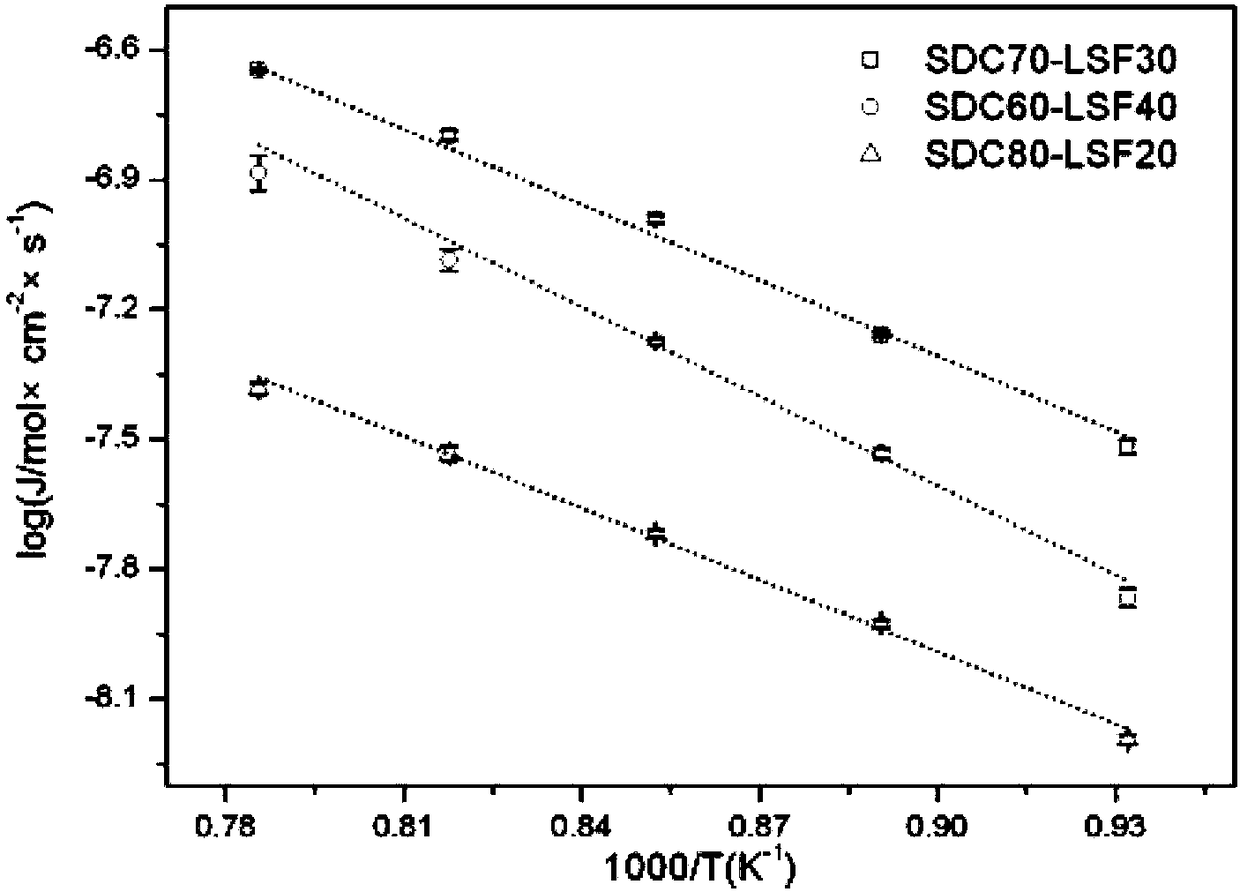

[0082] The steps are as in Example 1, and the purge gas is replaced with CO 2 When purging, the gas flow rate is 40ml min -1 ; When CO is used as the sweep gas, the flow rate is 20ml min -1 . Figure 4 It is the variation curve of oxygen permeability of SDC-LSF dual-phase composite membrane with the volume content of LSF at 900 °C, where the purge gases are He and CO, respectively. It can be seen from the figure that the SDC70–LSF30 biphasic oxygen permeable membrane has the highest oxygen permeability, and the oxygen permeability reaches 1.02×10 under the air / He gradient. -7 mol cm -2 ·s -1 ; Under the air / CO gradient, the oxygen permeability reached 6.42×10 -7 mol cm -2 ·s -1 . According to the percolation theory, an important factor affecting the two-phase mixed conductor oxygen permeable membrane is the internal connection characteristics of the two phases in the composite membrane. figure 2 The BSEM image shows that LSF cannot form a continuous internal connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com