Preparation method of natural high-concentration black tea essence

A technology of black tea essence and high concentration, which is applied in the fields of tea fragrance and food science, which can solve the problems of potential safety hazards, overall incoordination, and low product concentration, and achieve the effects of good aroma coordination, clear and transparent appearance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

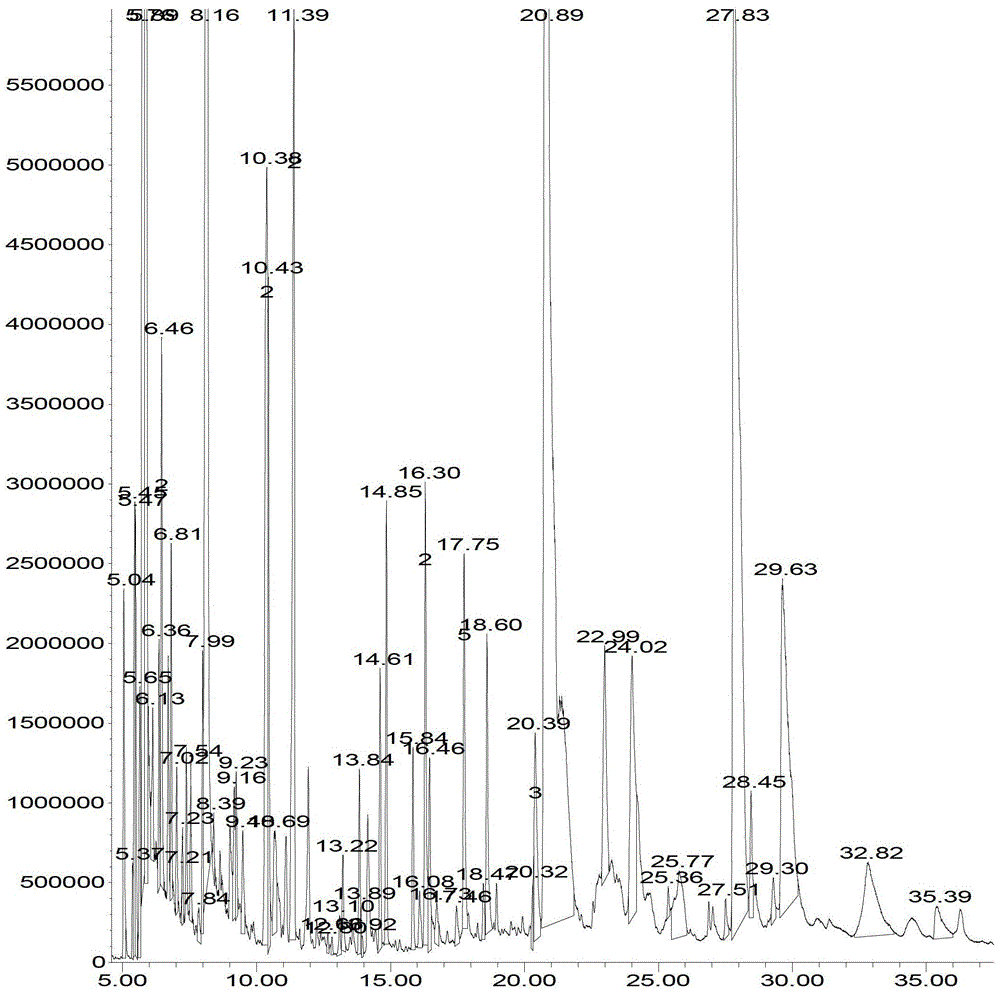

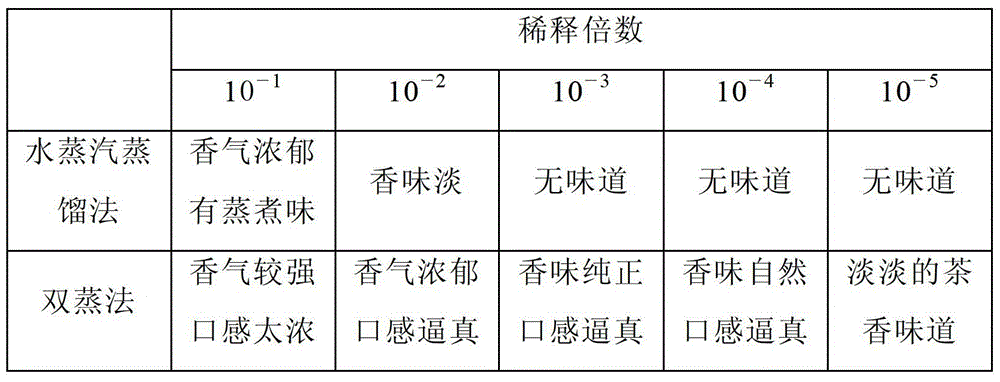

Image

Examples

Embodiment 1

[0022] (1) Put the impurity-free and mildew-free Dianhong tea into a closed extraction tank with a steam heating and condensing device, turn on the steam heating and condensing system, and pass in steam for distillation. The pressure of the steam is 500Kpa, and the condensate The outflow rate is 1.0L / min, the outflow temperature of the condensate is controlled at 30-40°C, and the condensate is collected to obtain black tea distillate A;

[0023] (2) When the black tea distillate A obtained in the collection step (1) reaches 4.5 times the weight of the raw material (based on the tea raw material), the collection is stopped, and it is refrigerated for later use, and the refrigerated temperature is controlled at 5-10°C;

[0024] (3) Extract the black tea distillate A obtained through steps (1) and (2) using the SCC (Spinning Cone Column) method, and set the working parameters of the SCC system. The specific parameters are: the system temperature is 100°C; the black tea distillatio...

Embodiment 2

[0026] Same as Example 1, the difference is: the present embodiment adopts Keemun black tea as raw material, and the outflow speed of condensate increases in step (1), and the Keemun black tea without impurities and mildew is dropped into a sealed belt with steam heating and In the extraction tank of the condensing device, turn on the steam heating and condensing system, feed water vapor for distillation, the pressure of the water vapor is 500Kpa, the outflow rate of the condensate is 1.5L / min, and the condensate is collected to obtain black tea distillate A. At the same time, reduce the amount of condensate collected in step (2). When it reaches 4 times the weight of raw materials (based on tea raw materials), stop collecting, refrigerate for standby, and control the temperature at 5-10°C. Increasing the outflow speed of the condensate and reducing the collection amount of the condensate can achieve the same effect, shorten the processing cycle and reduce the production cost. ...

Embodiment 3

[0028] Same as Example 2, except that the raw material used in this example is Ceylon black tea. In step (3), the feed temperature of the material is reduced and the temperature difference between the feed temperature and the temperature of the SCC system is increased, and the obtained A liquid is used in SCC (Spinning Cone Distillation Column) method for extraction, set the working parameters of the SCC system, the specific parameters are: system temperature is 100°C; feed rate is 600L / H; material temperature is 95°C; the temperature difference between the feed temperature and the system is -5°C; the external extraction rate is 2.6-2.8%, and the natural high-concentration black tea essence B is obtained. The same effect can be achieved by changing the feed temperature and the temperature difference between the feed temperature and the SCC system temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com