Oversized-section hollow corrugated split conductor

A technique for dividing conductors and corrugated shapes, applied in the direction of conductors, insulated conductors, non-insulated conductors, etc., can solve problems such as low softness, increased line loss, and increased difficulty, so as to improve transmission capacity, increase conductor cross-section, and reduce adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

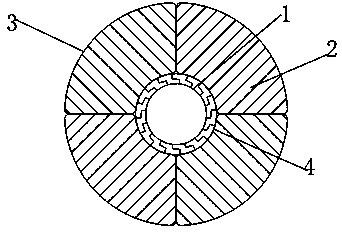

[0023] like figure 1 A super-large cross-section hollow split conductor is shown, the conductor is a combined hollow split conductor structure; a layer of Z-shaped conductor single-wire layer 1 is arranged in the center of the conductor; four pieces of corrugated conductors are arranged outside the Z-shaped conductor single-wire layer 1 A conductor strand layer 3 formed by strands 2; an isolated insulating crepe paper 4 is arranged between the conductor strand layer 3 and the self-supporting hollow outer Z-shaped conductor single wire layer 1 .

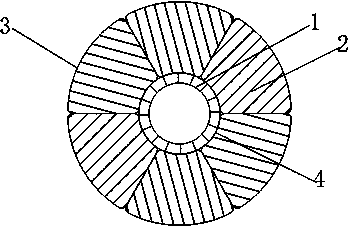

[0024] like figure 2 shown, with figure 1 The difference lies in that: there is a tile-shaped conductor single-wire layer 1 in the center of the conductor; and a conductor strand layer 3 composed of six corrugated-shaped conductor strands 2 is arranged outside the tile-shaped conductor single-wire layer 1 .

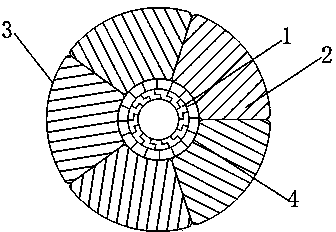

[0025] like imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com