Pipeline system capable of utilizing biogas slurry efficiently

A pipeline system and biogas slurry technology, which is applied in agriculture and the environment, can solve the problems of low filtration efficiency and difficulty in biogas slurry utilization, and achieve the effects of improving filtration efficiency, preventing and controlling various diseases and insect pests, and having broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

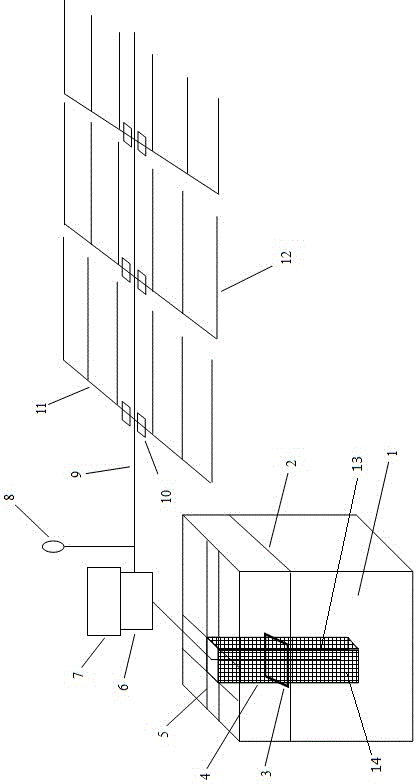

[0022] Example 1: Corn Biogas Slurry Pipeline System and Utilization

[0023] Such as figure 1 , Pipeline utilization of biogas slurry in corn fields. The corn field is rectangular, with an area of 45*115m. Biogas slurry pool 1 is located in the middle of one side of the field, in a square shape, with a side length of 5.3m, a pool depth of 2.4m, and a volume of biogas slurry of 60m 3 about. The surroundings of the filter box 4 are fixed with brackets 5 and placed in the middle of the biogas slurry tank 1 with an area of 1m 2 , 2m deep, consisting of a steel frame 13 and a steel wire mesh 14, the steel wire mesh 14 is wrapped on the periphery of the steel frame on three sides, with the opening upward; the mesh of the steel mesh is 60 mesh. The anti-blocking ring 3 is set on the outside of the filter box 4 and floats on the liquid surface 2 of the biogas slurry. One end of the booster pump 6 is put into the biogas slurry filter box 4, and the lower port is placed below ...

Embodiment 2

[0024] Embodiment 2: the filtering effect of the filter screen of the pipeline system according to the present invention

[0025] The fresh biogas slurry in this example is taken from the biogas slurry storage pond of Huawei pig farm biogas project in Huai'an, and the biogas project operates normally all year round. The difference between the pipeline system for high-efficiency utilization of biogas slurry used in Example 1 is that the test site of Example 2 is a laboratory test, and the steel mesh meshes are 40 mesh and 60 mesh. After transporting back, observe 40 mesh and 60 mesh. The maximum particle size in the biogas slurry under the condition of mesh filter pore size, the results are shown in Table 1:

[0026] Table 1 The maximum particle size in biogas slurry under the condition of 40 mesh and 60 mesh filter pore size

[0027] Filter porosity 40 mesh 60 mesh Maximum particle size on mesh surface (mm) 1.1 0.7 Mycelium status on the mesh surface...

Embodiment 3

[0028] Embodiment 3: Comparison of the effects of the pipeline system of the present invention and the traditional biogas slurry spraying method

[0029] The test site is Datian, Liuhe Animal Science Experimental Base of Jiangsu Academy of Agricultural Sciences. The biogas slurry comes from the liquid storage tank of the pig farm biogas project in the base, and the biogas project operates all year round. Biogas slurry filtration method is the same as in Example 1. Under the condition that the diesel engine power is 2.8kw and the booster pump power is 1.1kw, the micro-irrigation described in Example 1 is compared with the traditional three biogas slurry utilization methods of sprinkler irrigation and drip irrigation, and the results are shown in Table 2.

[0030] Table 2 Results of three biogas slurry utilization methods

[0031] Biogas slurry utilization method sprinkler irrigation The micro-irrigation system described in embodiment 1 traditional drip irrigat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com