3D (three-dimensional) printing porous metal stent of composite magnetic nano material and preparation method of 3D printing porous metal stent

A technology of porous metal and nanomaterials, applied in the field of biomedical materials, can solve the problems of lack of biological activity, insufficient mechanical strength, small application range, etc., and achieve the effect of strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Preparation of 3D printed porous metal scaffolds of composite magnetic nanomaterials

[0054] 1. Preparation of porous titanium alloy scaffold

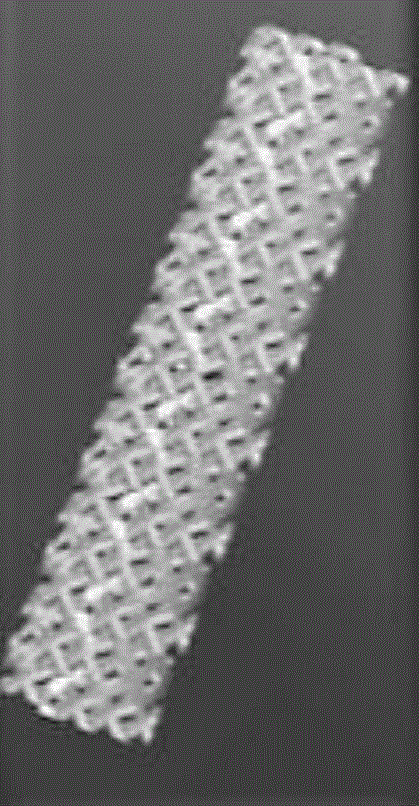

[0055] (1) Import the CT image into three-dimensional image software such as Mimics or CAD to obtain a three-dimensional image of the target bone tissue. The average pore column is 100 μm and the pore diameter is 300 μm. Personalized porous connected 3D digital model (such as figure 1 shown).

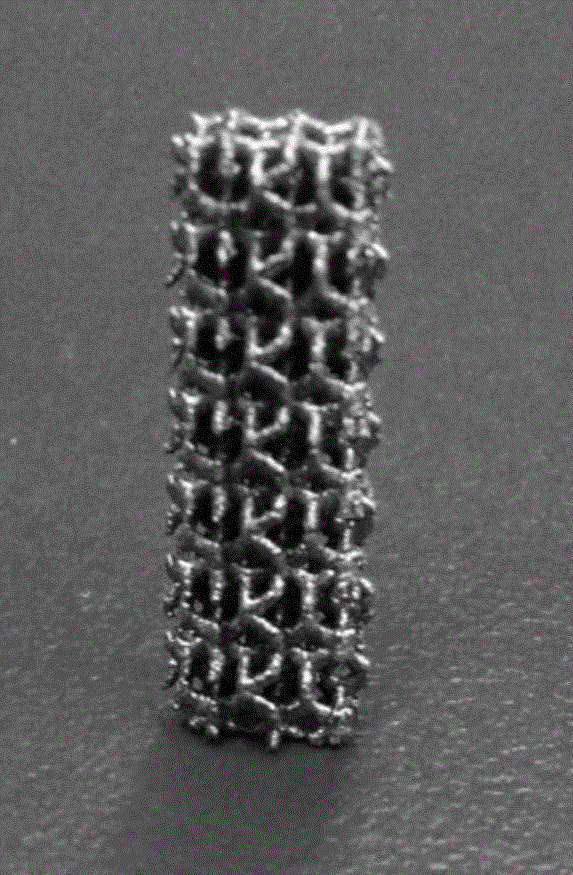

[0056] (2) EOS M280 metal material 3D printer was used to print porous titanium alloy scaffolds (such as figure 2 shown).

[0057] 2. Preparation of the mixture of magnetic particles, natural polymer materials and bioceramics

[0058] (1) Add 1.5% w / v gelatin particles into deionized water and soak for 2 hours, and at the same time stir at 37° C. with a magnetic stirrer at 300 r / min until completely dissolved.

[0059] (2) Nano-hydroxyapatite powder nHA (diameter 20nm) and γ-Fe 2 o 3 Added to gelatin solution, wherein t...

Embodiment 2

[0065] Example 2 Preparation of 3D printed porous metal scaffolds of composite magnetic nanomaterials

[0066] 1. Preparation of porous titanium alloy scaffold

[0067] (1) Import the CT image into three-dimensional image software such as Mimics or CAD to obtain a three-dimensional image of the target bone tissue. The average pore column is 300 μm and the pore diameter is 1000 μm. Personalized porous connected 3D digital model (such as figure 1 shown).

[0068] (2) EOS M280 metal material 3D printer was used to print porous titanium scaffolds (such as figure 2 shown).

[0069] 2. Preparation of the mixture of magnetic particles, natural polymer materials and bioceramics

[0070] (1) Add 3% w / v gelatin particles into deionized water and soak for 2 hours, and at the same time stir at 37° C. with a magnetic stirrer at 300 r / min until completely dissolved.

[0071] (2) Nano-hydroxyapatite powder nHA (diameter 20nm) and γ-Fe 2 o 3 Added to gelatin solution, wherein the mass...

Embodiment 3

[0077] Example 3 Preparation of 3D printed porous metal scaffolds of composite magnetic nanomaterials

[0078] 1. Preparation of porous titanium alloy scaffold

[0079] (1) Import the CT image into three-dimensional image software such as Mimics or CAD to obtain a three-dimensional image of the target bone tissue. The average pore column is 1000 μm and the pore diameter is 3000 μm. Personalized porous connected 3D digital model (such as figure 1 shown).

[0080] (2) EOS M280 metal material 3D printer was used to print porous titanium scaffolds (such as figure 2 shown).

[0081] 2. Preparation of the mixture of magnetic particles, natural polymer materials and bioceramics

[0082] (1) Add 5% w / v gelatin particles into deionized water and soak for 2 hours, and at the same time, stir at 37° C. with a magnetic stirrer at 300 r / min until completely dissolved.

[0083] (2) Nano-hydroxyapatite powder nHA (diameter 20nm) and γ-Fe 2 o 3 Added to gelatin solution, wherein the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com