Spray washing device of wet type electric dust remover

A technology of wet electrostatic precipitator and flushing device, which is applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., which can solve the problems of complex system, inability to form water film, easy corrosion, etc., and achieve enhanced dust removal effect and reduced corrosion effect , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

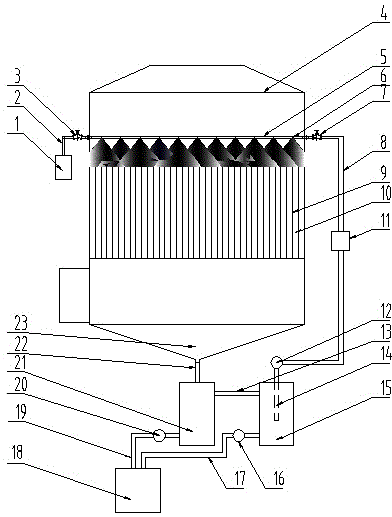

[0023] This embodiment provides a wet electrostatic precipitator spray flushing device, including desulfurization process water source 1, water pipeline 2, electric control valve (1) 3, spray water pipe 5, nozzle 6, electric control valve (2) 7, Circulating water pipe 8, filter 11, circulating water pump 12, connecting pipe 13, liquid suction pipe 14, circulating water tank 15, circulating water tank sewage pump 16, circulating water tank sewage pipe 17, desulfurization sewage pool 18, sewage tank sewage pipe 19, sewage tank Sewage pump 20, sewage tank 21, ash hopper sewage pipe 22.

[0024] The above-mentioned water delivery pipe 2 is connected to the spray water pipe 5 above the interior of the casing 4 from one side, and the circulating water pipe 8 is connected to the spray water pipe 5 above the interior of the casing 4 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com