Corrosion inhibitor for reinforced concrete and preparation method thereof

A technology of reinforced concrete and rust inhibitor, which is applied in the field of building materials, can solve problems such as improving concrete and aggravating corrosion, and achieves the effects of low equipment dependence, inhibition of steel corrosion, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

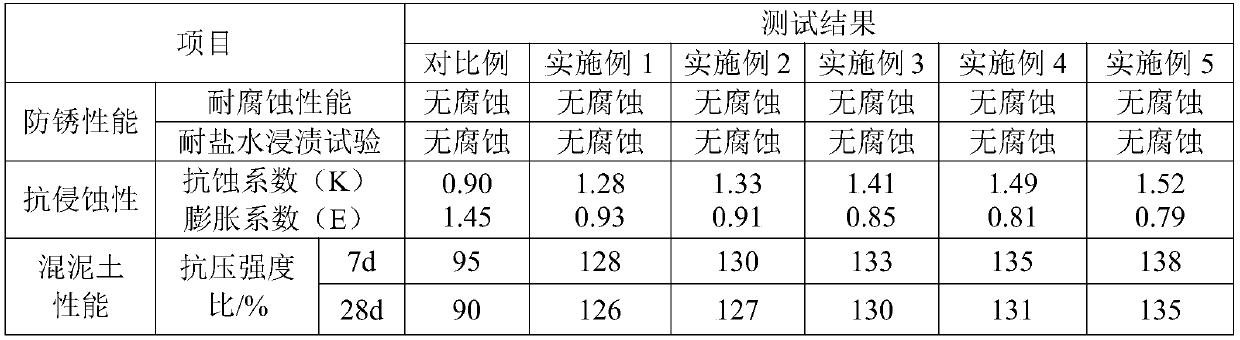

Examples

Embodiment 1

[0030] A rust inhibitor for reinforced concrete, consisting of the following components by weight: 10 parts of surface modified Mo-Zn-Dy-O-B, (1R,2R,3S,4R,6S)-4,6-diamino- 2,3-dihydroxycyclohexyl 6-amino-6-deoxy-alpha-D-glucopyranoside 10 parts, epoxy glycoside modified {(2S)-2-{bis[3,5-bis(tri Fluoromethyl)phenyl]hydroxymethyl}-1-pyrrolidinyl[4-(1-pyrrolidinyl)-3-pyridyl]methanone 15 parts, water 60 parts, alkylbenzenesulfonate primer Air agent 0.01 part.

[0031]The epoxy glycoside modified {(2S)-2-{bis[3,5-bis(trifluoromethyl)phenyl]hydroxymethyl}-1-pyrrolidinyl[4-(1-pyrrolidine base)-3-pyridyl]methanone preparation method, comprising the steps of: {(2S)-2-{bis[3,5-bis(trifluoromethyl)phenyl]hydroxymethyl}-1- Add 17g of pyrrolidinyl[4-(1-pyrrolidinyl)-3-pyridyl]methanone, 10g of 3,4-epoxybutyl-beta-cellobioside, and 3g of sodium carbonate into 100g of dimethyl sulfoxide , stirred and reacted at 90°C for 4 hours, then filtered to remove insoluble salts, and then rotary ev...

Embodiment 2

[0037] A rust inhibitor for reinforced concrete, consisting of the following components by weight: 11 parts of surface modified Mo-Zn-Dy-O-B, (1R,2R,3S,4R,6S)-4,6-diamino- 2,3-dihydroxycyclohexyl 6-amino-6-deoxy-alpha-D-glucopyranoside 11 parts, epoxy glycoside modified {(2S)-2-{bis[3,5-bis(tri Fluoromethyl)phenyl]hydroxymethyl}-1-pyrrolidinyl[4-(1-pyrrolidinyl)-3-pyridyl]methanone 16 parts, water 63 parts, ferric saponin air-entraining agent 0.02 share.

[0038] The epoxy glycoside modified {(2S)-2-{bis[3,5-bis(trifluoromethyl)phenyl]hydroxymethyl}-1-pyrrolidinyl[4-(1-pyrrolidine base)-3-pyridyl]methanone preparation method, comprising the steps of: {(2S)-2-{bis[3,5-bis(trifluoromethyl)phenyl]hydroxymethyl}-1- Pyrrolidinyl[4-(1-pyrrolidinyl)-3-pyridyl]methanone 17g, 3,4-epoxybutyl-beta-cellobioside 10g, potassium carbonate 3.5g were added to N,N-di In 110 g of methylformamide, the reaction was stirred at 93° C. for 4.5 hours, then the insoluble salt was removed by filtrati...

Embodiment 3

[0044] A rust inhibitor for reinforced concrete, consisting of the following components by weight: 13 parts of surface modified Mo-Zn-Dy-O-B, (1R,2R,3S,4R,6S)-4,6-diamino- 2,3-dihydroxycyclohexyl 6-amino-6-deoxy-alpha-D-glucopyranoside 13 parts, epoxy glycoside modified {(2S)-2-{bis[3,5-bis(tri Fluoromethyl)phenyl]hydroxymethyl}-1-pyrrolidinyl[4-(1-pyrrolidinyl)-3-pyridyl]methanone 18 parts, water 65 parts, alkylbenzenesulfonate primer Air agent 0.03 parts.

[0045] The epoxy glycoside modified {(2S)-2-{bis[3,5-bis(trifluoromethyl)phenyl]hydroxymethyl}-1-pyrrolidinyl[4-(1-pyrrolidine base)-3-pyridyl]methanone preparation method, comprising the steps of: {(2S)-2-{bis[3,5-bis(trifluoromethyl)phenyl]hydroxymethyl}-1- Pyrrolidinyl[4-(1-pyrrolidinyl)-3-pyridyl]methanone 17g, 3,4-epoxybutyl-beta-cellobioside 10g, sodium hydroxide 4g were added to N-methylpyrrolidone 130g, stirred and reacted at 95°C for 5 hours, then filtered to remove insoluble salts, and then rotary evaporated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com