Differential mechanism shell casting process

A differential housing and casting process technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of inability to guarantee the shape and position accuracy of the four cross shaft holes, low machining accuracy, and wear of boring tools. Achieve the effect of solving shrinkage cavity and shrinkage defects, reducing the amount of machining and cutting, and avoiding the formation of hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

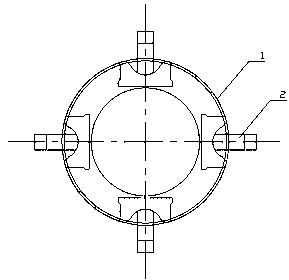

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

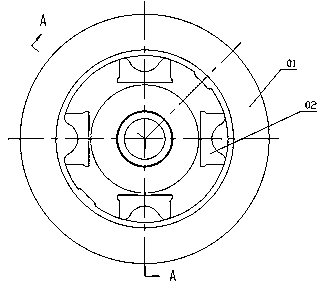

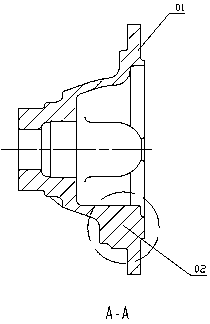

[0034] combined with image 3 to attach Figure 9 , a differential case casting process, it comprises the steps:

[0035] 1. A core making machine is used to produce a sand core main body 1. The sand core main body 1 is an integrated structure with a casting hole sand column 2 for casting a cross shaft hole on a differential case;

[0036] 2. Dry the sand core main body 1 described in step 1;

[0037] 3. Place the sand core main body 1 after drying in step 2 in the upper and lower molds of the differential case, and then cast the molds according to the conventional casting process;

[0038] Four, finally open the casting mold to obtain the differential case 4 with the cross shaft hole 6 .

[0039] Preferably, the core-making machine is a core-shooting machine that uses a hot box process to make coated sand cores.

[0040] The conventional casting method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com