Coagulant for industrial water pretreatment

A technology for industrial water and pretreatment, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. Slow speed and other problems, to achieve the effect of improving effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

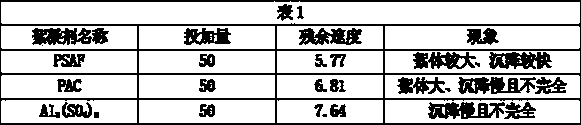

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A coagulant for industrial water pretreatment according to the present invention comprises coal-based granular activated carbon and polyaluminum-ferric silicate, and the mass-volume ratio of the two is 2:1.

[0029] The above-mentioned coal-based granular activated carbon has a particle size of 0.35-0.45mm and an apparent density of 0.35-0.42.

Embodiment 2

[0031] A coagulant for industrial water pretreatment according to the present invention comprises coal-based granular activated carbon and polyaluminum-ferric silicate, and the mass-volume ratio of the two is 8:1.

[0032] The above-mentioned coal-based granular activated carbon has a particle size of 0.35-0.45mm and an apparent density of 0.35-0.42.

Embodiment 3

[0034] A coagulant for industrial water pretreatment according to the present invention comprises coal-based granular activated carbon and polyaluminum-ferric silicate, and the mass-volume ratio of the two is 12:1.

[0035] The above-mentioned coal-based granular activated carbon has a particle size of 0.35-0.45mm and an apparent density of 0.35-0.42.

[0036] The coal-based granular activated carbon used in the present invention has unique advantages because of its high strength, well-developed pores, large specific surface area, and especially large micropore volume. Coal-based activated carbon has a strong adsorption capacity for organic matter, free chlorine and harmful gases in the air. It is an excellent adsorbent for deep purification of urban drinking water and is used to remove bacteria and toxic gases in the air. Coal-based activated carbon has a well-developed pore structure, good chemical stability and mechanical strength, and is an excellent broad-spectrum carbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com