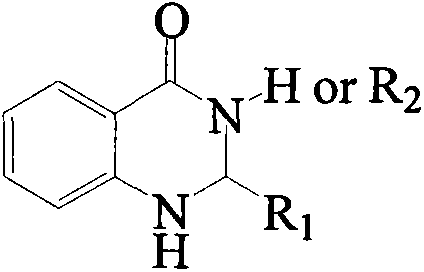

Synthesis method for substituted 2, 3-dihydro-4(1H)-quinazolinone compound

A technology of quinazolinone and synthesis method, applied in the field of substitution 2, can solve the problems of expensive catalyst, use of toxic reagents, long reaction time and the like, and achieve the effects of short synthesis time, high product yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

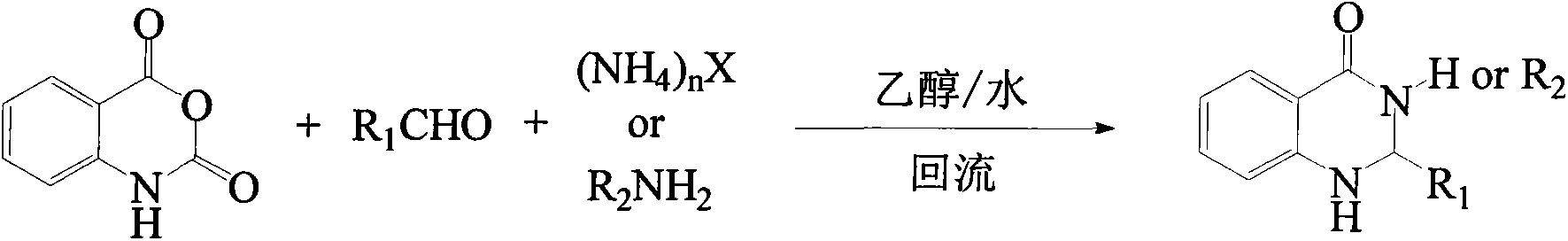

Method used

Image

Examples

Embodiment 1

[0017] Add 110mmol isatoic anhydride, 100mmol benzaldehyde, 110mmol ammonium carbonate, 50mL ethanol / water mixed solution (volume ratio 1:3) to a 500mL reaction flask, heat and stir under reflux for 1h. After the reaction, the reaction bottle was cooled to room temperature, washed with ethanol / water (volume ratio 1:1), and filtered to obtain a crude product. The crude product was obtained by further recrystallization from absolute ethanol. The product is a white crystal with a yield of 90% and a melting point of 225-226°C.

[0018] IR(KBr): 3304, 3188, 1652, 1615, 1507, 1392, 1300, 1149, 748cm -1 ;

[0019] 1 H NMR (500MHz, DMSO-d 6 ): δ8.32(s, 1H), 7.62(d, J=7.2Hz, 1H), 7.50(d, J=6.8Hz, 2H), 7.42~7.35(m, 3H), 7.25(t, J= 8.4Hz, 1H), 7.14(s, 1H), 6.75(d, J=8.0Hz, 1H), 6.68(t, J=7.2Hz, 1H), 5.76(s, 1H);

[0020] Elemental Analysis C 14 h 12 N 2 O, found (calculated) (%): C 74.80 (74.98), H 5.51 (5.39), N 12.55 (12.49).

Embodiment 2

[0022] Add 110mmol isatoic anhydride, 100mmol 3-nitrobenzaldehyde, 110mmol ammonium carbonate, 50mL ethanol / water mixed solution (volume ratio 1:3) to a 500mL reaction flask, heat and stir under reflux for 2.7h. After the reaction, the reaction bottle was cooled to room temperature, washed with ethanol / water (volume ratio 1:1), and filtered to obtain a crude product. The crude product was obtained by further recrystallization from absolute ethanol. The product is a yellow crystal with a yield of 91% and a melting point of 200-202°C.

[0023] IR(KBr): 3337, 3147, 1673, 1635, 1526, 1386, 1187, 772cm -1 ;

[0024] 1H NMR (500MHz, DMSO-d 6 ): δ8.76(d, J=7.4Hz, 2H), 8.42(t, J=7.5Hz, 2H), 7.97(brs, 1H), 7.87(dt, J=6, 7.5Hz, 2H), 7.62 (brs, 1H), 7.57(t, J=6.2Hz, 1H), 7.38(t, J=7.5Hz, 1H), 7.26(s, 1H);

[0025] Elemental Analysis C 14 h 11 N 3 o 3 , found (calculated) (%): C 62.31 (62.45), H 4.07 (4.12), N 15.70 (15.61).

Embodiment 3

[0027] Add 110mmol isatoic anhydride, 100mmol 4-chlorobenzaldehyde, 110mmol ammonium acetate, 50mL ethanol / water mixed solution (volume ratio 1:3) to a 500mL reaction flask, heat and stir under reflux for 1h. After the reaction, the reaction bottle was cooled to room temperature, washed with ethanol / water (volume ratio 1:1), and filtered to obtain a crude product. The crude product was obtained by further recrystallization from absolute ethanol. The product is a white crystal with a yield of 90% and a melting point of 206-207°C.

[0028] IR (KBr): 3309, 3188, 1655, 1611, 1509, 1386, 1153, 753cm -1 ;

[0029] 1 H NMR (500MHz, DMSO-d 6 ): δ8.35(s, 1H), 7.62(d, J=8.8Hz, 2H), 7.49(dd, J=8.8, 8.8Hz, 3H), 7.26(t, J=7.6, 8.8Hz, 1H) , 7.15(s, 1H,), 6.75(d, J=8.0Hz, 1H), 6.69(t, J=7.2, 7.6Hz, 1H), 5.77(s, 1H);

[0030] Elemental Analysis C 14 h 11 N 2 OCl, found (calculated) (%): C 65.19 (65.00), H 4.23 (4.29), N 10.75 (10.83).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com