Water-based electroplating sealing gloss oil and preparation method thereof

A water-based and varnish technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as difficulties in international exchanges and cooperation, small VOC emissions, unfavorable improvement of coating technology level, etc., to ensure clarity and VOC emissions Reduced, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

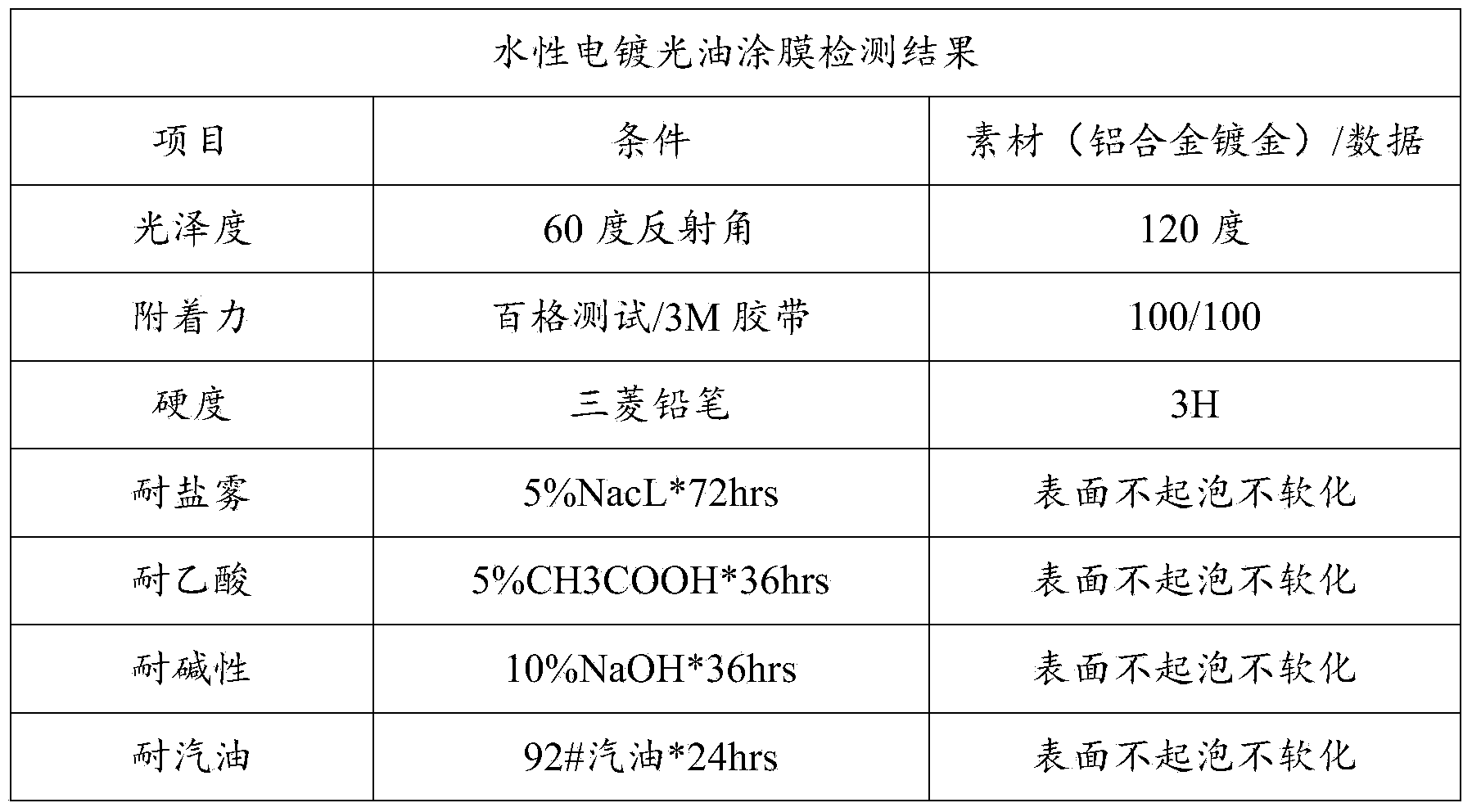

Image

Examples

Embodiment 1

[0026] The water-based electroplating sealing varnish described in the present embodiment is made from the raw materials of the following mass ratios:

[0027] Raw material composition of varnish

The role of each component

The mass percentage of each component

Waterborne thermosetting acrylic resin

Provide adhesion hardness salt spray resistance

30%

Waterborne methyl etherified amino resin

Provides bridging cure acid etch resistance

5%

Salt Spray Resistance Auxiliary

Provides salt spray resistance

4%

Provides adhesion promotion

0.3%

Leveling Auxiliary (Efka)

Provide long-wave leveling of coating film

0.5%

Defoaming additive (Efka)

Provide defoaming properties of coatings

0.2%

IPA

Thinner

20%

Ethylene glycol butyl ether BCS

Thinner

10%

Propylene glycol methyl ether acetate PMA

Thinner

15%

Neutrali...

Embodiment 2

[0036] The water-based electroplating sealing varnish described in the present embodiment is made from the raw materials of the following mass ratios:

[0037] Raw material composition of varnish

[0038] Waterborne methyl etherified amino resin

[0039] The preparation process of the water-based electroplating sealing varnish described in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0041] The water-based electroplating sealing varnish described in the present embodiment is made from the raw materials of the following mass ratios:

[0042] Raw material composition of varnish

[0043] The preparation process of the water-based electroplating sealing varnish described in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com