Gel rust remover for aerugo of gilding layer

A technology of rust remover and gel, applied in the field of cultural relics protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

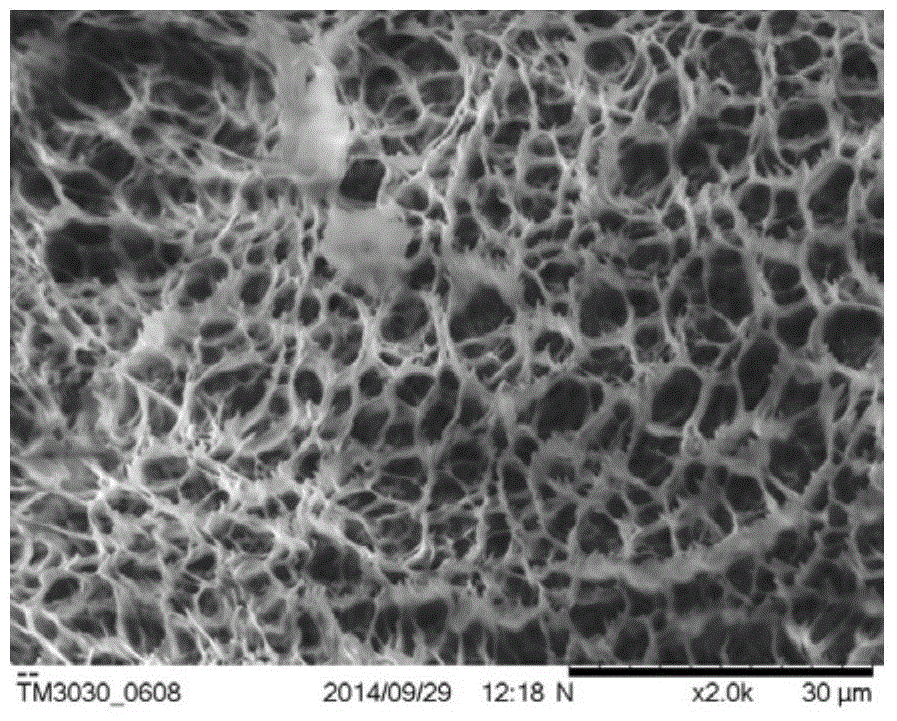

[0029] Heat 50g of distilled water to 85-90°C, add 1.0g of polyvinyl alcohol 1799, stir until the polyvinyl alcohol 1799 is completely dissolved, stop heating, cool the solution to 55°C, add 4.0g of Carbomer 940 by a small amount After adding Carbomer 940, it was observed that there will be a small amount of Carbomer agglomeration, and then continue to stir until the aqueous solution becomes transparent, and then add 0.05g triethanolamine, 0.01g borax, 0.01g formic acid, 0.01 g cysteine, cooled to room temperature, added to 100g with distilled water, to obtain the gilt layer patina gel rust remover. Depend on figure 1 It can be seen that the gel rust remover has a typical three-dimensional network pore structure. Measured by the NDJ-8S rotational viscometer, its viscosity at the 3RPM speed of the No. 4 rotor is too large, beyond the range of the NDJ-8S rotational viscometer, and cannot be measured.

Embodiment 2

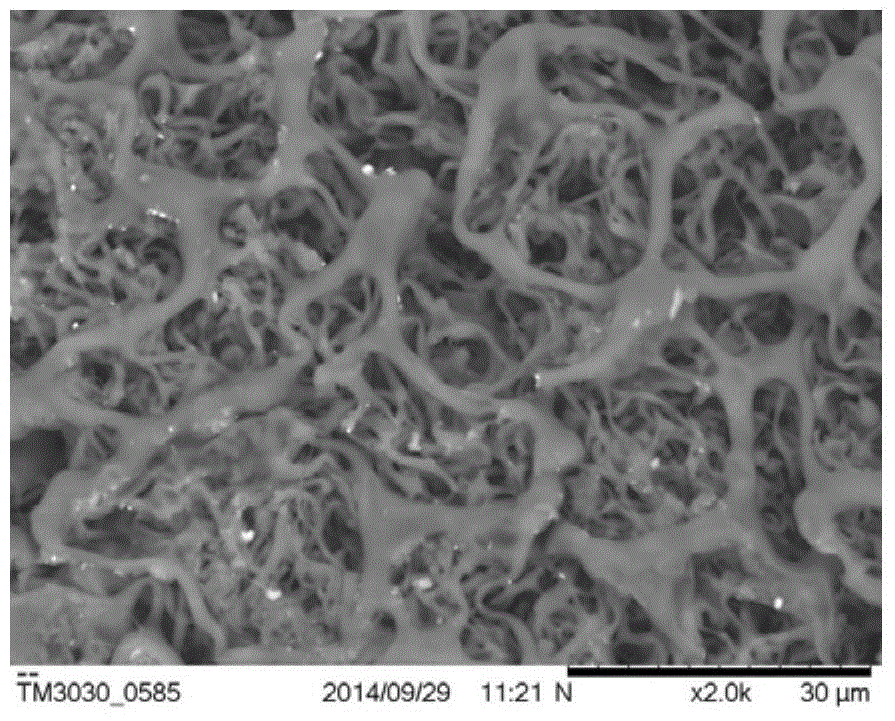

[0031] Heat 50g of distilled water to 85-90°C, add 1.0g of polyvinyl alcohol 1799, stir until the polyvinyl alcohol 1799 is completely dissolved, stop heating, cool the solution to 55°C, add 1.0g of Carbomer 940 in small amounts After adding Carbomer 940, it was observed that there will be a small amount of Carbomer agglomeration, and then continue to stir until the aqueous solution becomes transparent, and then add 0.05g triethanolamine, 0.01g borax, 0.01g formic acid, 0.01 g cysteine, cooled to room temperature, added to 100g with distilled water, to get the gilt layer patina gel rust remover (see figure 2 ). Measured by the NDJ-8S rotational viscometer, its viscosity at the 3RPM speed of No. 4 rotor is 594000mPa·s.

Embodiment 3

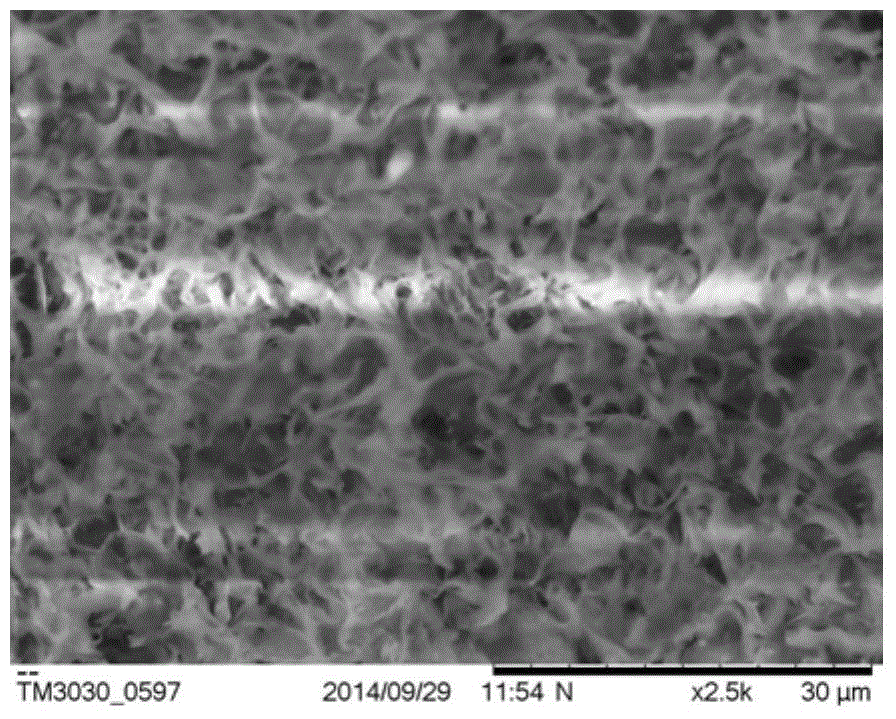

[0033] Heat 50g of distilled water to 85-90°C, add 1.0g of polyvinyl alcohol 1799, stir until the polyvinyl alcohol 1799 is completely dissolved, stop heating, cool the solution to 55°C, add 2.0g of Carbomer 940 by a small amount After adding Carbomer 940, it was observed that there will be a small amount of Carbomer agglomeration, and then continue to stir until the aqueous solution becomes transparent, and then add 0.05g triethanolamine, 0.01g borax, 0.01g formic acid, 0.01 g cysteine, cooled to room temperature, added to 100g with distilled water, to get the gilt layer patina gel rust remover (see image 3 ). Measured by the NDJ-8S rotational viscometer, its viscosity at the 3RPM speed of the No. 4 rotor is 1312000mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com