Automobile power reducer

A technology for automobiles and power, applied in vehicle components, machines/engines, heating/cooling equipment, etc., can solve the problems of increasing the engine, failing to achieve supercharging effect, and low practicability, so as to reduce the internal resistance of intake air and save energy Fuel effect, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing and implementation.

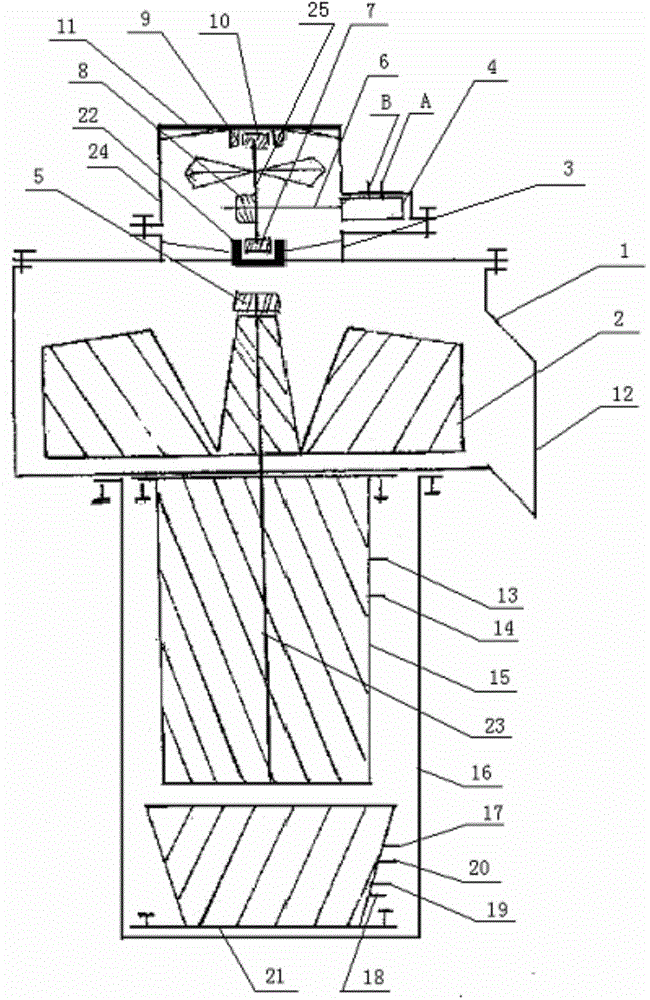

[0054] The structure of the automobile power reducer of the present invention is as follows: figure 1 As shown, an automobile power reducer is composed of a casing, an air intake device, an impeller, a motor, and a control device.

[0055] The casing is composed of a main casing 1 , an upper casing 3 , a front casing 24 and a rear cover 16 . The upper part of the front shell 24 is provided with an air inlet 11 , and the side of the main shell 1 is provided with an air outlet 12 .

[0056] The air inlet device is arranged in the front shell 24, and the air inlet device is composed of a micro switch 4, a micro push rod 6, a fan shaft 25, a fan shaft cam 8, an upper bearing 10, an upper bearing seat 9, and a lower bearing 7. , The lower bearing seat 22 constitutes. The fan blade shaft 25 is equipped with a fan blade and a fan blade shaft cam 8, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com