Pollution-free electron multiplier assembly system and assembly method thereof

An electron multiplier and assembly system technology, which is applied in the manufacture of electrode systems, installation/disassembly of discharge tubes/lamp auxiliary devices, circuits, etc., can solve the problems of complex assembly and many parts of electron multipliers, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below with reference to the drawings.

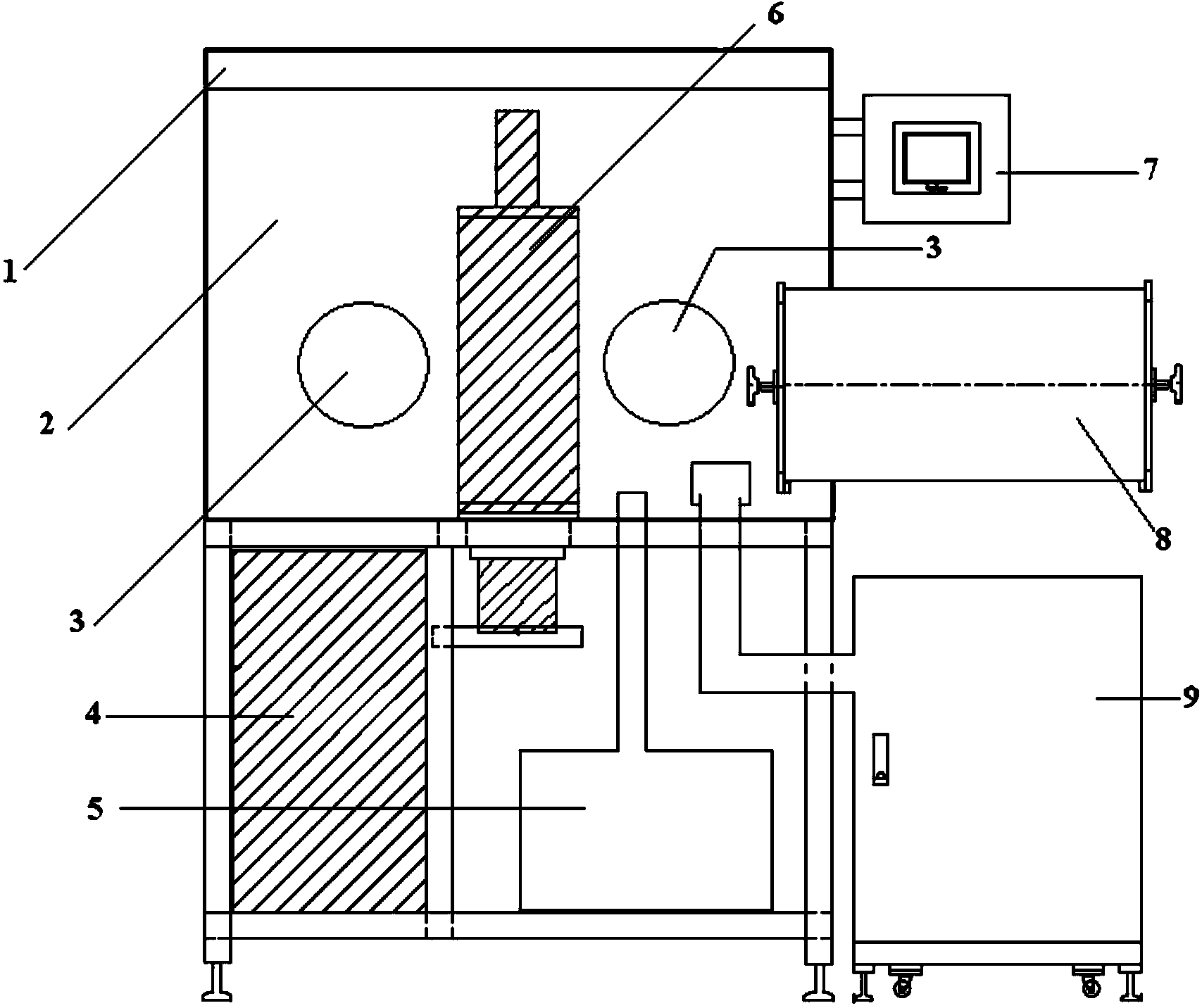

[0029] Such as figure 1 As shown, the electron multiplier pollution-free assembly system includes: main box 2, lighting system 1, operating gloves 3, electric welding machine control system 4, vacuum pumping system 5, electric welding machine 6, control system 7, transition chamber 8 and gas purification system.

[0030] The main box body 2 provides a closed space, which requires excellent sealing performance, and good sealing performance is the key to ensure the performance and safety of the equipment. The side of the main box is made of corrosion-resistant stainless steel, and the front viewing window is made of transparent tempered glass.

[0031] The interior of the main box 2 is provided with a lighting system 1 , operating gloves 3 and an electric welding machine 6 . in,

[0032] The illumination system 1 is located at the upper front part of the main cabinet and ado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com