Modified hydrophilic acrylic resin film

An acrylic resin and modification technology are applied in the field of modified acrylic resin films and laminates formed by laminating the modified acrylic resin films, which can solve the problems of low durability and inability to withstand long-term use, and achieve hydrophilicity. Improved, high-performance anti-fog properties, improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0168] Hereinafter, the present invention will be described in more detail using examples and the like, but the present invention is not limited to these examples.

[0169] In addition, in this invention, the physical property evaluation of a film was performed as follows.

[0170]

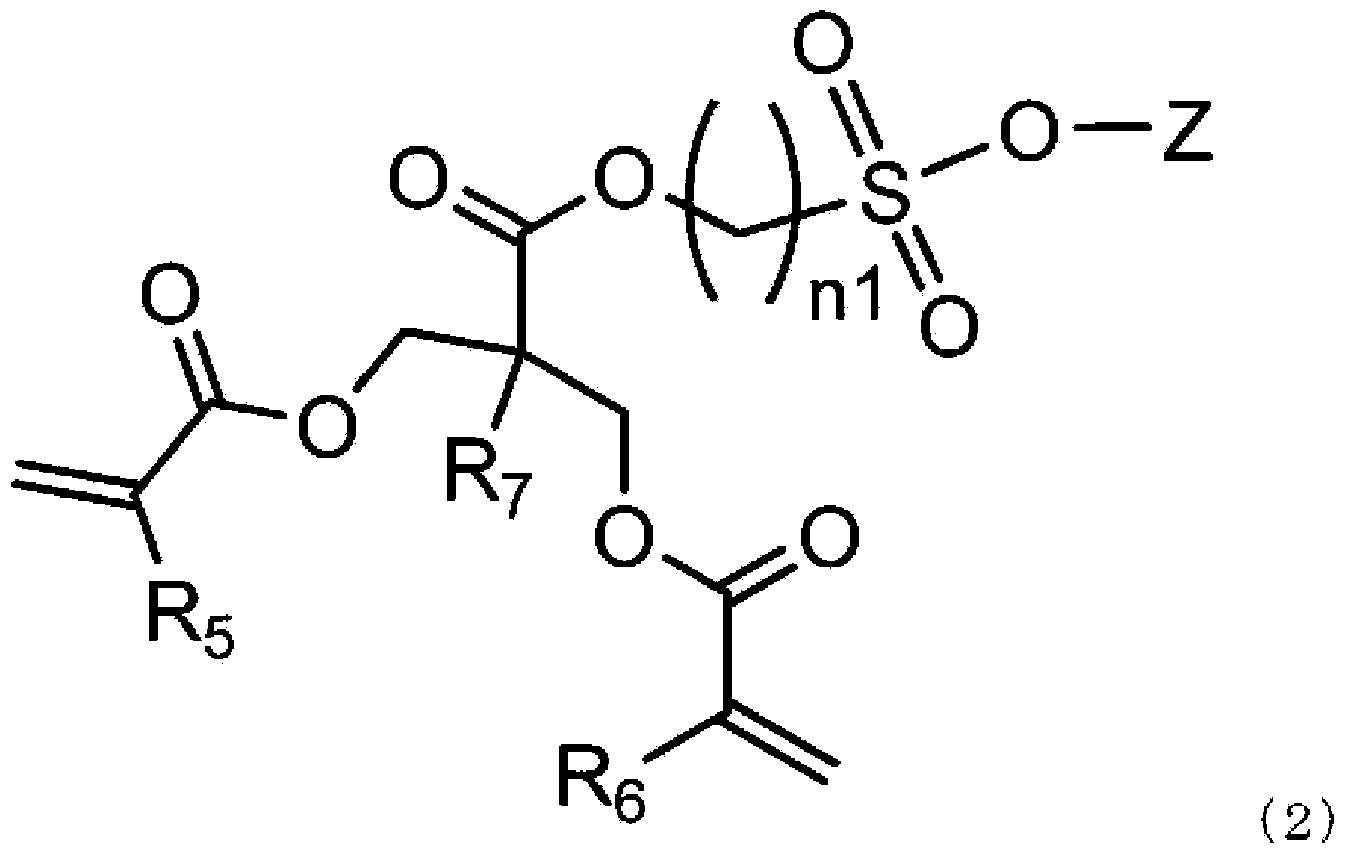

[0171] Apply an acrylic resin-based coating solution to a substrate and dry it with a solvent, and measure the 808 cm before and after UV irradiation. -1 of>C=CH 2 The peak intensity (baseline method) was used to calculate the degree of polymerization using the following formula.

[0172] Polymerization degree (mol%) = (peak intensity before UV irradiation - peak intensity after UV irradiation) / peak intensity before UV irradiation × 100

[0173]

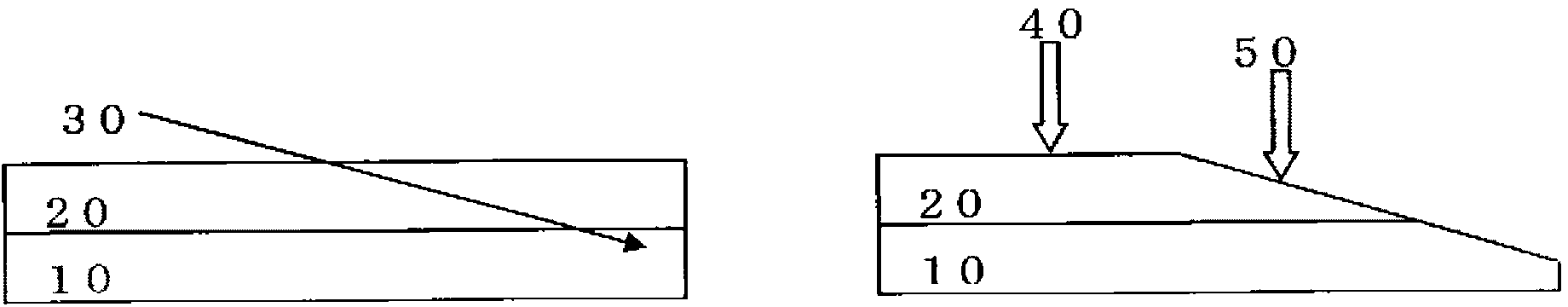

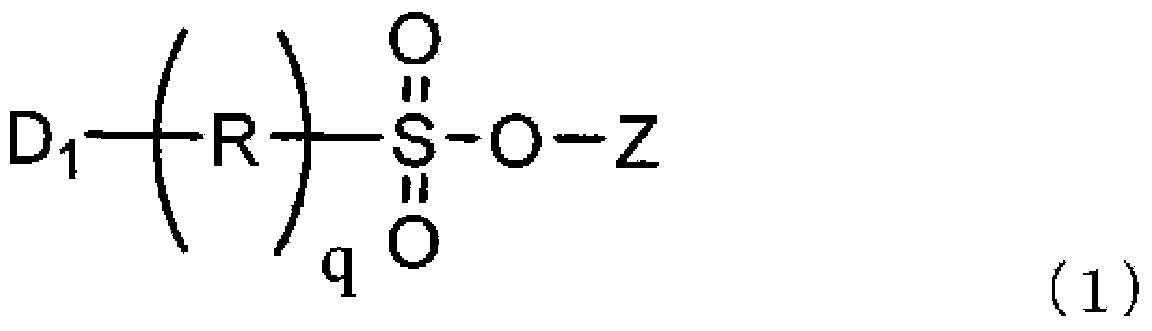

[0174] Such as figure 1 As shown in the sample preparation, the sample was cut obliquely, and the anion concentration (Sa) at the above-mentioned outer surface and the anion concentration (Da) at the above-mentioned middle position were measured...

manufacture example 1

[0201] [Manufacture Example 1] Manufacture of a coated surface (hydrophilic membrane) having an anionic hydrophilic group

[0202] (Preparation of coating solution 1)

[0203] According to the compounding ratio in Table 1, a uniform coating solution 1 with a solid content of 65 wt% was prepared.

[0204] [Table 1]

[0205] Table 1 Coating solution 1

[0206]

[0207]

[0208]

[0209]

[0210] To 10.0 g of a mixed solution of 8.3 g of cyclohexane and 1.7 g of toluene, add 1.0 g of the hydrophilic compound SPA-K: 3-sulfopropyl acrylate potassium salt, which forms the inclined film of the present invention, and stir at 25°C After 1 hour, filtration was performed with a 0.45 μm membrane filter.

[0211] The obtained filtrate was placed in an evaporating dish, heated and dried at 150° C. for 2 hours, cooled to room temperature, and the weight of the residue was measured.

[0212] Finally, the solubility in cyclohexane:toluene=5:1 (weight ratio) was calculated|requir...

Embodiment 1

[0222] First, according to Table 3, a treatment solution for grafting the surface of the membrane obtained in Production Example 1 was prepared.

[0223] [table 3]

[0224] Table 3 grafting treatment solution

[0225]

[0226]

[0227] With bar coater #20, the graft treatment liquid that obtains is coated on the coating film surface of manufacture example 1, carries out 2~3 minutes drying with the warm air drier of 40~50 ℃, then makes it pass through UV conveyor ( Fusion UV Systems, Japan, electrodeless discharge lamp H bulb, output 100%, conveyor speed 6m / min) 1 time (cumulative light amount 900mJ / cm 2 ), while carrying out the grafting treatment on the surface of the coating film, the film is fully cured. Finally, the surface of the obtained coating film was washed with running water while lightly wiping it with a sponge made of polyurethane, dried with a warm air dryer, and then cooled to room temperature to complete the coating. The results are shown in Table 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com