Lactating sow complete formula feed for improving milk quality

A technology for lactating sows and compound feed, which is applied to the field of full-price compound feed for lactating sows, can solve problems such as prolonged non-production days, and achieve the effects of reducing feed costs, maintaining a balanced ratio and enhancing immunity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

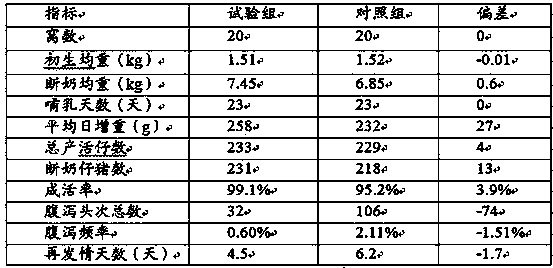

Examples

Embodiment 1

[0018] Composed of the following components by weight: 62 kg of northeast corn, 13 kg of soybean meal, 6 kg of fermented soybean meal, 5 kg of rice bran meal, 1.5 kg of imported Peruvian fish meal, 2 kg of wheat germ powder, 1.5 kg of yeast culture, and 1.26 kg of stone powder , 0.9 kg of calcium hydrogen phosphate, 0.39 kg of table salt, 0.45 kg of amino acid compound package, 3 kg of emulsified oil powder, 2 kg of premix, and 1 kg of Chinese herbal medicine additives.

[0019] Production method: feed the above-mentioned large-scale granular raw materials such as corn, wheat, soybean meal, etc. in proportion and pass through the initial cleaning and sieving treatment, then use a 2.5 mm sieve grinder to crush the above-mentioned raw materials into powder, and add small proportions of components according to the above-mentioned weight After 120 seconds of mixing by the mixer to make the mixture uniform, granulate with a granulator at a vapor pressure of 0.25 Mpa and a temperatur...

Embodiment 2

[0021] The following components are composed by weight: 50 kg of northeast corn, 10 kg of wheat, 13 kg of soybean meal, 4 kg of fermented soybean meal, 2 kg of rice bran meal, 2 kg of imported Peruvian fish meal, 4 kg of bran, 2.9 kg of wheat germ powder, Yeast culture 2 kg, stone powder 1.3 kg, calcium hydrogen phosphate 1 kg, salt 0.4 kg, amino acid compound package 0.4 kg, emulsified oil powder 4 kg, premix 2 kg, Chinese herbal medicine additive 1 kg.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] Composed of the following components by weight: 56 kg of northeast corn, 8 kg of wheat, 14 kg of soybean meal, 2 kg of fermented soybean meal, 2.8 kg of imported Peruvian fish meal, 4 kg of bran, 1 kg of wheat germ powder, and 1 kg of yeast culture , 1.15 kg of stone powder, 1.2 kg of calcium hydrogen phosphate, 0.5 kg of salt, 0.35 kg of amino acid compound package, 5 kg of emulsified oil powder, 2 kg of premix, and 1 kg of Chinese herbal medicine additives.

[0025] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com