Composite 3D printing porous metal support for demineralized bone matrix and preparation method of metal support

A decalcified bone matrix and 3D printing technology, applied in the field of biomedical materials, can solve the problems of unfavorable cell adhesion, inability to realize three-dimensional microenvironment cell culture, difficulty in achieving cell growth, matrix secretion and filling, etc., to achieve The effect of maximizing bone ingrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 Preparation of 3D printed porous metal scaffold of composite decalcified bone matrix

[0058] 1. Preparation of porous titanium alloy scaffold

[0059] (1) Import the CT image into three-dimensional image software such as Mimics or CAD to obtain a three-dimensional image of the target bone tissue. The average pore column is 100 μm and the pore diameter is 300 μm. Personalized porous connected 3D digital model (such as figure 1 shown).

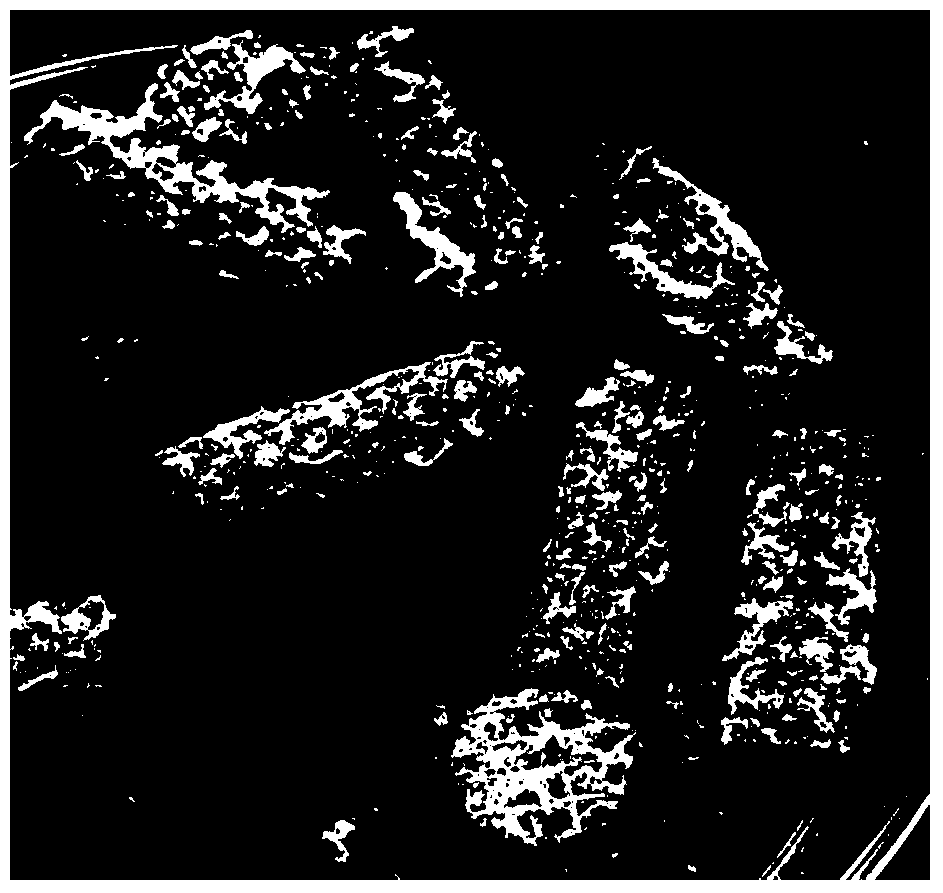

[0060] (2) EOS M280 metal material 3D printer was used to print porous titanium scaffolds (such as figure 2 shown).

[0061] 2. Preparation of decalcified bone matrix

[0062] (1) Take some corpses of New Zealand white rabbits, and cut off their limbs;

[0063] (2) Separate the bones and tissues of the limbs, and remove the periosteum, cartilage and tissues on the surface;

[0064] (3) The obtained limb bones were washed and stored in a -80°C refrigerator for later use;

[0065] (4) Take some New Zealand white rabbit li...

Embodiment 2

[0077] Example 2 Preparation of 3D printed porous metal scaffold of composite decalcified bone matrix

[0078] 1. Preparation of porous titanium alloy scaffold

[0079] (1) Import the CT image into three-dimensional image software such as Mimics or CAD to obtain a three-dimensional image of the target bone tissue. The average pore column is 300 μm and the pore diameter is 1000 μm. Personalized porous connected 3D digital model (such as figure 1 shown).

[0080] (2) EOS M280 metal material 3D printer was used to print porous titanium scaffolds (such as figure 2 shown).

[0081] 2. Preparation of decalcified bone matrix

[0082] (1) Take some corpses of New Zealand white rabbits, and cut off their limbs;

[0083] (2) Separate the bones and tissues of the limbs, and remove the periosteum, cartilage and tissues on the surface;

[0084] (3) The obtained limb bones were washed and stored in a -80°C refrigerator for later use;

[0085] (4) Take some New Zealand white rabbit l...

Embodiment 3

[0097] Example 3 Preparation of 3D printed porous metal scaffold of composite decalcified bone matrix

[0098] 1. Preparation of porous titanium alloy scaffold

[0099] (1) Import the CT image into three-dimensional image software such as Mimics or CAD to obtain a three-dimensional image of the target bone tissue. The average pore column is 1000 μm and the pore diameter is 3000 μm. Personalized porous connected 3D digital model (such as figure 1 shown).

[0100] (2) EOS M280 metal material 3D printer was used to print porous titanium scaffolds (such as figure 2 shown).

[0101] 2. Preparation of decalcified bone matrix

[0102] (1) Take some corpses of New Zealand white rabbits, and cut off their limbs;

[0103] (2) Separate the bones and tissues of the limbs, and remove the periosteum, cartilage and tissues on the surface;

[0104] (3) The obtained limb bones were washed and stored in a -80°C refrigerator for later use;

[0105] (4) Take some New Zealand white rabbit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com