A 3D printed porous metal scaffold with composite decalcified bone matrix and its preparation method

A decalcified bone matrix and 3D printing technology, which is applied in the field of biomedical materials, can solve the problems of unfavorable cell attachment, difficulty in achieving cell growth, matrix secretion and filling, and inability to achieve three-dimensional microenvironment cell culture. The effect of maximizing bone ingrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 Preparation of 3D printed porous metal scaffold with composite demineralized bone matrix

[0058] 1. Preparation of porous titanium alloy scaffold

[0059] (1) Import the CT image into 3D imaging software such as Mimics or CAD to obtain a 3D image of the target bone tissue. The average pore column is 100μm and the pore diameter is 300μm. Fill and expand the image with regular hexahedron and regular dodecahedron structure units. Personalized three-dimensional digital model of porous connectivity (such as figure 1 Shown).

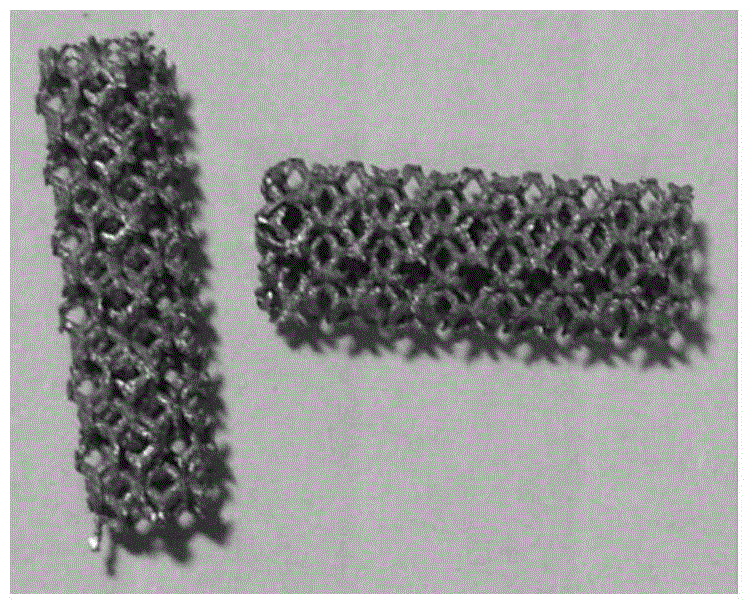

[0060] (2) Using EOS M280 metal material 3D printer, using titanium alloy (Ti-6Al-4V) as raw material, printing porous titanium stents (such as figure 2 Shown).

[0061] 2. Preparation of decalcified bone matrix

[0062] (1) Take several corpses of New Zealand white rabbits and cut off their limbs;

[0063] (2) Separate the bones and tissues of the limbs, and remove the surface periosteum, cartilage and tissues;

[0064] (3) The obtained limb bones are...

Embodiment 2

[0077] Example 2 Preparation of 3D printed porous metal scaffold with composite demineralized bone matrix

[0078] 1. Preparation of porous titanium alloy scaffold

[0079] (1) Import the CT image into 3D image software such as Mimics or CAD to obtain a 3D image of the target bone tissue. The average pore column is 300μm and the pore diameter is 1000μm. Fill and expand the image with regular hexahedron and regular dodecahedron structure units. Personalized three-dimensional digital model of porous connectivity (such as figure 1 Shown).

[0080] (2) Using EOS M280 metal material 3D printer, using titanium alloy (Ti-6Al-4V) as raw material, printing porous titanium stents (such as figure 2 Shown).

[0081] 2. Preparation of decalcified bone matrix

[0082] (1) Take several corpses of New Zealand white rabbits and cut off their limbs;

[0083] (2) Separate the bones and tissues of the limbs, and remove the surface periosteum, cartilage and tissues;

[0084] (3) The obtained limb bones are ...

Embodiment 3

[0097] Example 3 Preparation of 3D printed porous metal scaffold with composite demineralized bone matrix

[0098] 1. Preparation of porous titanium alloy scaffold

[0099] (1) Import the CT image into 3D image software such as Mimics or CAD to obtain a 3D image of the target bone tissue. The average pore column is 1000μm and the pore size is 3000μm. Fill and expand the image with regular hexahedron and regular dodecahedron structure units. Personalized three-dimensional digital model of porous connectivity (such as figure 1 Shown).

[0100] (2) Using EOS M280 metal material 3D printer, using titanium alloy (Ti-6Al-4V) as raw material, printing porous titanium stents (such as figure 2 Shown).

[0101] 2. Preparation of decalcified bone matrix

[0102] (1) Take several corpses of New Zealand white rabbits and cut off their limbs;

[0103] (2) Separate the bones and tissues of the limbs, and remove the surface periosteum, cartilage and tissues;

[0104] (3) The obtained limb bones are was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com