A glass melting furnace quantitative pulse bubbling device

A glass melting furnace and bubbling device technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of insufficient operation accuracy and stability, aggravating the negative impact of bubbling on the flushing of bubbling bricks at the bottom of the furnace, etc. Achieve the effect of eliminating the natural fluctuation phenomenon of reversing combustion, eliminating defects completely, and stabilizing the liquid flow

Active Publication Date: 2017-07-14

广东华兴玻璃股份有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the size of the bubbling bubble diameter (gas volume) is easily affected by fluctuations in process factors such as melting temperature, flame length, and stockpile distribution, especially in the periodic cycle of flame combustion exchange. And the glass liquid temperature fluctuates greatly. For glass varieties with high requirements on product quality, especially the strict control of small bubbles or microbubbles, it is not suitable due to insufficient operation accuracy and stability.

In addition, if there is a pulse-interval shielding gas in this type of system, it will intensify the negative impact of bubbling under the unstable melting process of the pool furnace and the erosion of the bubbling bricks at the bottom of the furnace.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

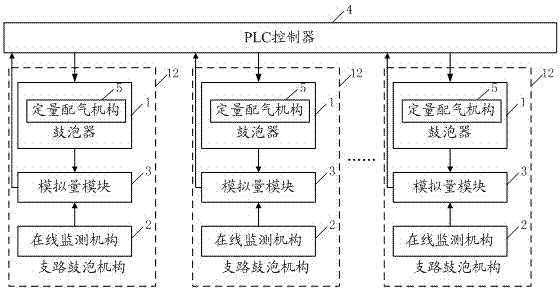

[0057] Embodiment: A quantitative variable frequency pulse bubbling device with 20 branch bubbling mechanisms 12 arranged in a row.

[0058] Reference example: 20 bubblers and 1 line-by-line double-time variable frequency pulse bubbler device are used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

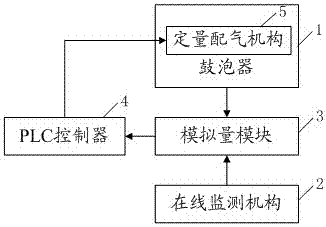

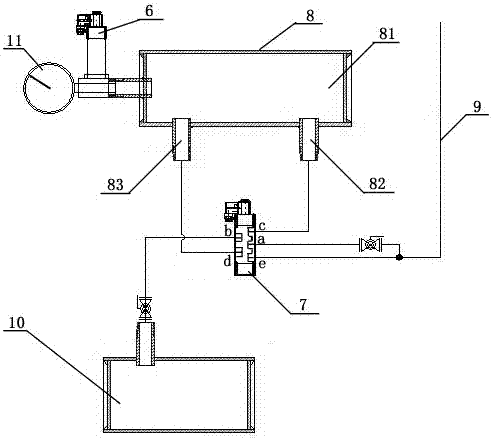

The invention discloses a quantitative pulse bubbling device used in a glass melting kiln. The quantitative pulse bubbling device comprises a bubbler, an online monitoring mechanism, an analog module and a PLC, wherein the bubbler is provided with a quantitative gas distribution mechanism, the online monitoring mechanism is arranged inside the glass melting kiln so as to measure the real-time temperature and viscosity of molten glass, the analog module is respectively connected with the PLC and the quantitative gas distribution mechanism and the PLC controller is connected with the quantitative gas distribution mechanism so as to control the bubbling frequency and the gas amount. By the quantitative pulse bubbling device, the diameter of the bubbled bubble can be accurately controlled, the bubbling frequency is automatically varied in real time so that the molten glass flows stably, the material discharge temperature is high and small in fluctuation, the degree of homogenization is high and the quality of the product is high.

Description

technical field [0001] The invention relates to glass bubbling technology, in particular to a quantitative pulse bubbling device for a glass melting furnace. Background technique [0002] Bubbling is a new technology of forced melting that appeared in the 1950s. In the mid-1970s, my country began to apply bubbling technology to brown and green bottle glass tank kilns. The bubbling technology of glass melting furnace was once developed in the 1980s and 1990s, but due to the limitation of production technology, it has not been fully developed. With the advancement of science and technology, after 30 years of research and improvement, large and medium-sized glass furnaces built in recent years have begun to use bubbling technology. This technology has been extended from bottle glass to the melting of other glass varieties. Such as container glass, medical glass, borosilicate glass, high-lead glass, fiber glass, patterned glass, float glass, electronic glass and water glass. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C03B5/193

CPCC03B5/193

Inventor 李深华李名班艾必有

Owner 广东华兴玻璃股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com