Low-temperature high-concentration polycarboxylic acid water reducing agent and preparation method thereof

A polycarboxylate and superplasticizer technology, applied in the field of polycarboxylate superplasticizers, can solve problems such as failure to meet production requirements and inability to react, achieve rapid growth and termination of free radicals, and are extremely easy to operate and implement. The effect of slow acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

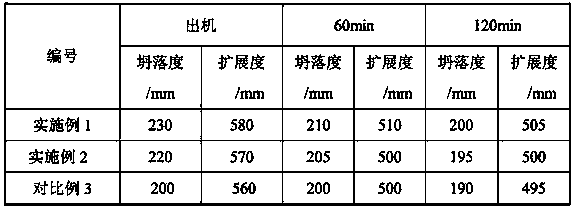

[0033]According to the requirements of high-performance concrete in the Bailifeng area of Xinjiang section of Lanzhou-Xinjiang Railway, C30 grade concrete was prepared. Among them, the cement is Tianshan low-alkali cement PO 42.5, the fly ash is grade II ash, the sand is medium sand with a fineness modulus of 2.8 (mud content 3.5%), and the gravel is a continuous gradation of 5-25mm (mud content 1.5%), the amount of superplasticizer is 1.0% of the amount of gelling material, and the relative air humidity is 20%. Carry out experiments according to the following mixing ratio: cement: fly ash: sand: stone: water: admixture = 269:145:709:1020:160:4.14 (unit: Kg); basic requirements for concrete: machine slump 220±20mm, loss of no more than 15% in 2 hours, no segregation or bleeding of concrete. According to the above requirements, the trial mix of concrete was carried out, and the results are shown in Table 1.

[0034] Table 1 Concrete performance test results

[0035]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com