Polyphenylene sulfide desalting method

A technology of polyphenylene sulfide and reactor, which is applied in the desalination field of polyphenylene sulfide synthesized by sodium sulfide method, can solve the problems of poor desalination effect, high energy consumption, large amount of solvent, etc., and achieves the convenience of industrial production and Popularization and application, simple equipment, and the effect of simplifying the purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

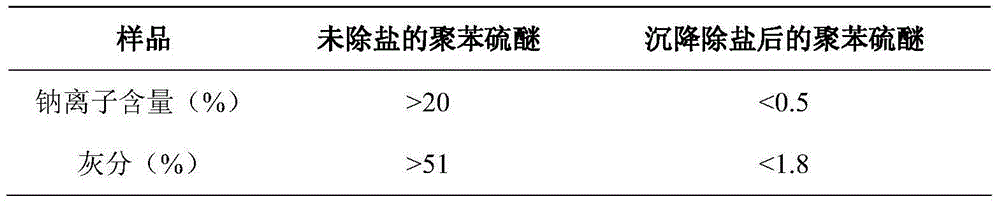

Embodiment 1

[0037] After the polyphenylene sulfide synthesis reaction is completed, stop stirring, keep the reaction kettle warm at 220°C, keep the reaction pressure and let it stand for 20 minutes to allow the by-product salt and reaction additives to settle to the bottom of the kettle. After the settlement is over, replace the air in the storage tank with nitrogen before the polyphenylene sulfide solution is moved to the storage tank. After the replacement, the pressure in the storage tank is maintained at 0 MPa; Balanced with tank pressure. Then, the temperature of the polyphenylene sulfide solution in the storage tank was lowered to 150° C., so that the polyphenylene sulfide was precipitated from the reaction solution to form a suspension; the suspension in the storage tank was filtered to obtain a polyphenylene sulfide filter cake. Adding N-methylpyrrolidone into the reaction kettle containing salt, stirring under the conditions of reaction temperature and pressure during polyphenyle...

Embodiment 2

[0039] After the polyphenylene sulfide synthesis reaction is completed, stop stirring, keep the reaction kettle warm at 230° C., keep the reaction pressure and let stand for 35 minutes to allow the by-product salt and reaction additives to settle to the bottom of the kettle. After the settlement is over, replace the air in the storage tank with nitrogen before the polyphenylene sulfide solution is moved to the storage tank. After the replacement, the pressure in the storage tank is maintained at 0 MPa; Balanced with tank pressure. Then, the temperature of the polyphenylene sulfide solution in the storage tank was lowered to 130° C., so that the polyphenylene sulfide was precipitated from the reaction solution to form a suspension; the suspension in the storage tank was filtered to obtain a polyphenylene sulfide filter cake. Adding N-methylpyrrolidone into the reaction kettle containing salt, stirring under the conditions of reaction temperature and pressure during polyphenylen...

Embodiment 3

[0041] After the synthesis reaction of polyphenylene sulfide, the stirring was stopped, and the reaction kettle was kept warm at 240° C., and the reaction pressure was kept for 45 minutes to allow the by-product salt and reaction additives to settle to the bottom of the kettle. After the settlement is over, replace the air in the storage tank with nitrogen before the polyphenylene sulfide solution is moved to the storage tank. After the replacement, the pressure in the storage tank is maintained at 0 MPa; Balanced with tank pressure. Then, the temperature of the polyphenylene sulfide solution in the storage tank was lowered to 120° C., so that the polyphenylene sulfide was precipitated from the reaction solution to form a suspension; the suspension in the storage tank was filtered to obtain a polyphenylene sulfide filter cake. Adding N-methylpyrrolidone into the reaction kettle containing salt, stirring under the conditions of reaction temperature and pressure during polypheny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com