Light absorbing and heat accumulating composition and light absorbing and heat accumulating structure prepared therefrom

A composition and heat storage technology, applied in the direction of heat exchange materials, rayon manufacturing, single-component polyester rayon, etc., can solve the problems of poor heat insulation ability and poor light transmittance, and achieve the best light transmittance , Good light absorption and heat generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of light-absorbing heat-storage composition

[0026] First, antimony tin oxide (purchased from Japan Ishihara Co.) and 3-aminopropyltriethoxysilane are added to alcohol with a volume percentage of 95%, and after being thoroughly mixed and stirred, an antimony tin oxide suspension is obtained . Wherein, the ratio of antimony to tin in the selected antimony tin oxide is 1:9, the particle size of the antimony tin oxide is 10-20 nanometers, and the antimony tin oxide: 3-aminopropyltriethoxy The weight ratio of silane:alcohol is 30:2:68.

[0027] Next, the antimony tin oxide suspension was continuously ball milled by a ball mill for 6 hours at a rotational speed of 1000 rpm using 1 mm zirconium beads to form a dispersed antimony tin oxide slurry.

[0028] Afterwards, the dispersed antimony-tin oxide slurry is spray-dried under the technological condition that the drying temperature is 100° C. to obtain a dried antimony-tin oxide mixed powder. The...

Embodiment 2

[0031] Embodiment 2: Preparation of light-absorbing heat-storage composition

[0032] In this example, the light-absorbing and thermal-storage composition is roughly prepared by the method of the above-mentioned Example 1, the difference is that stearic acid is added as a lubricant during the preparation process of this example, and the detailed preparation method is as follows:

[0033] Firstly, antimony tin oxide, 3-aminopropyltriethoxysilane and stearic acid are added into 95% alcohol by volume, and after being thoroughly mixed and stirred, the antimony tin oxide suspension is obtained. Among them, the weight ratio of antimony tin oxide: 3-aminopropyltriethoxysilane: stearic acid: alcohol is 30:1:1:68.

[0034]Next, the antimony tin oxide suspension was continuously ball milled by a ball mill for 6 hours at a rotational speed of 1000 rpm using 1 mm zirconium beads to form a dispersed antimony tin oxide slurry.

[0035] Afterwards, the dispersed antimony-tin oxide slurry is...

Embodiment 3

[0038] Embodiment 3: Preparation of light-absorbing heat-storage composition

[0039] In this example, the light-absorbing and thermal-storage composition was prepared roughly by the method of Example 1 above, the difference being that the dispersant used in this example was Solsperse 20000, which was purchased from Lubrizol, USA.

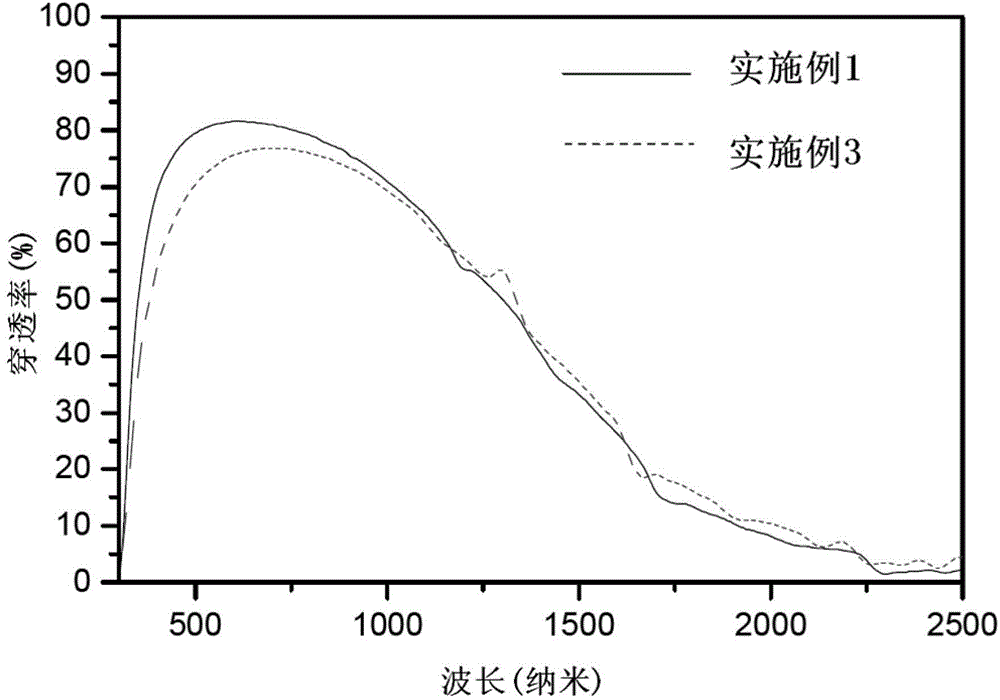

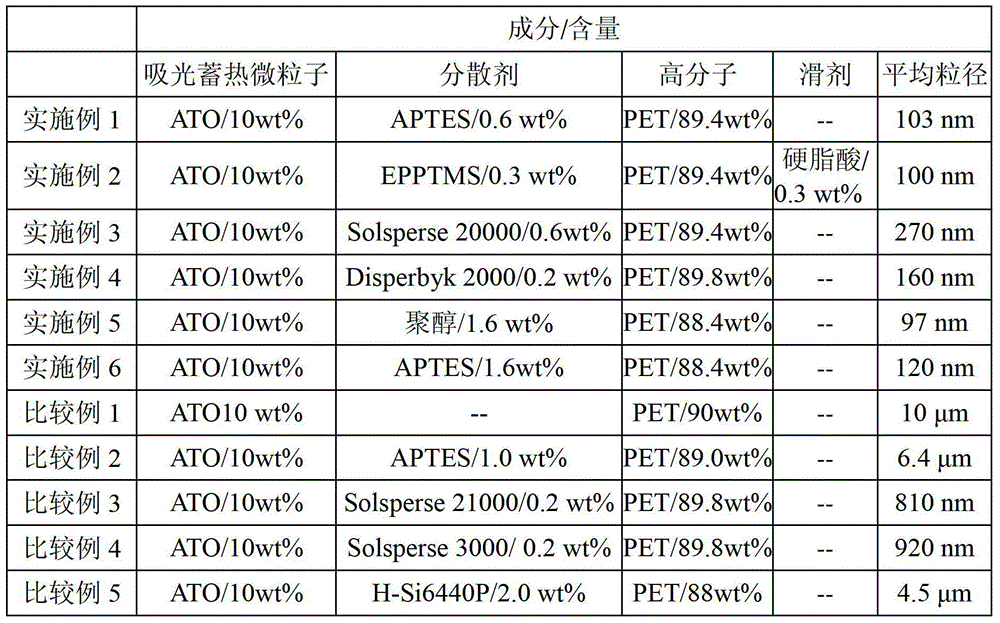

[0040] The specific components and contents of light-absorbing and heat-storage microparticles, dispersants and polymers in the light-absorbing and heat-storage composition prepared in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com