A kind of preparation method of high-efficiency spherical-like green phosphor for white LED

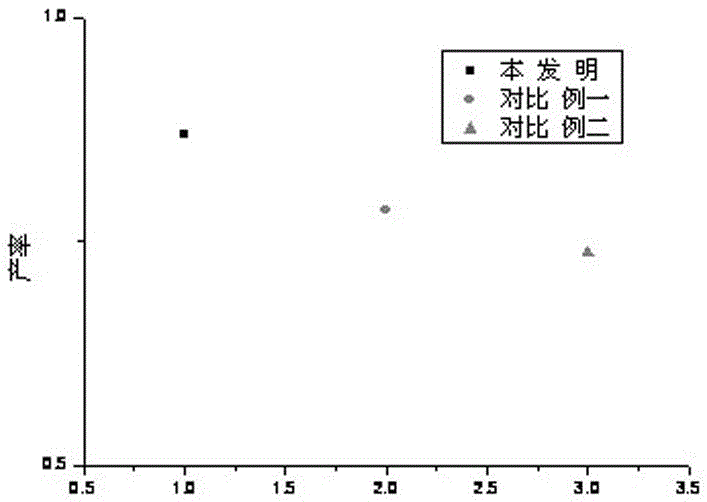

A technology of green fluorescent powder and spherical type, which is applied in the field of preparation of fluorescent materials for white light LEDs, can solve the problems of uneven distribution of green fluorescent powder particles and low luminous efficiency for white light LEDs, and achieve improved luminous quantum efficiency and crystallization High degree, the effect of reducing the existence of impurity phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

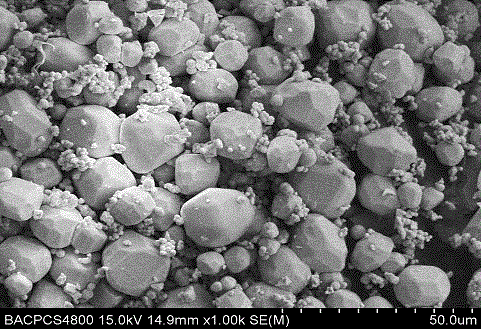

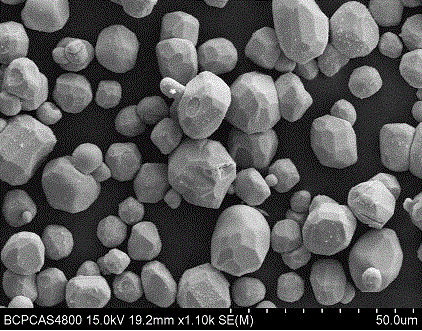

Embodiment 1

[0039] Weigh 119.38g Lu 2 o 3 , 50.98g Al 2 o 3 , 1.72g CeO 2 Add 1.72g of polyethylene oxide into 1L of deionized water, then put it into a ball mill tank, grind at 60rpm for 2h, and spray dry the obtained powder slurry. The outlet temperature of the spray dryer is 85°C. One-time sintering, the sintering atmosphere is air atmosphere, the sintering temperature is 1100°C, and the sintering time is 2h. The obtained powder is passed through a 100-mesh nylon sieve, and then mixed with 15.49g SrF 2 and 0.86g H 3 BO 3 , use a V-type mixer to mix for 3 hours, and then sinter in a reducing atmosphere. The sintering temperature is 1550 ° C, the sintering time is 2 hours, and the sintering atmosphere is H 2 :N 2 =3:2 (volume ratio), the sintered powder undergoes a post-processing process to form a product. The resulting product looks like figure 2 shown.

Embodiment 2

[0041] According to the process conditions described in Table 1, implement according to the method of Example 1, all examples can realize the object of the invention of the present invention.

[0042] Table 1

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com